Modular automatic arc door with concentric circle

A modular, automatic door technology, applied in the direction of revolving doors, wing leaf arrangement, door/window accessories, etc., can solve the problems of inconvenient operation, uneconomical, time-consuming and other problems, achieve simple and fast assembly, reduce assembly time, The effect of reducing assembly cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

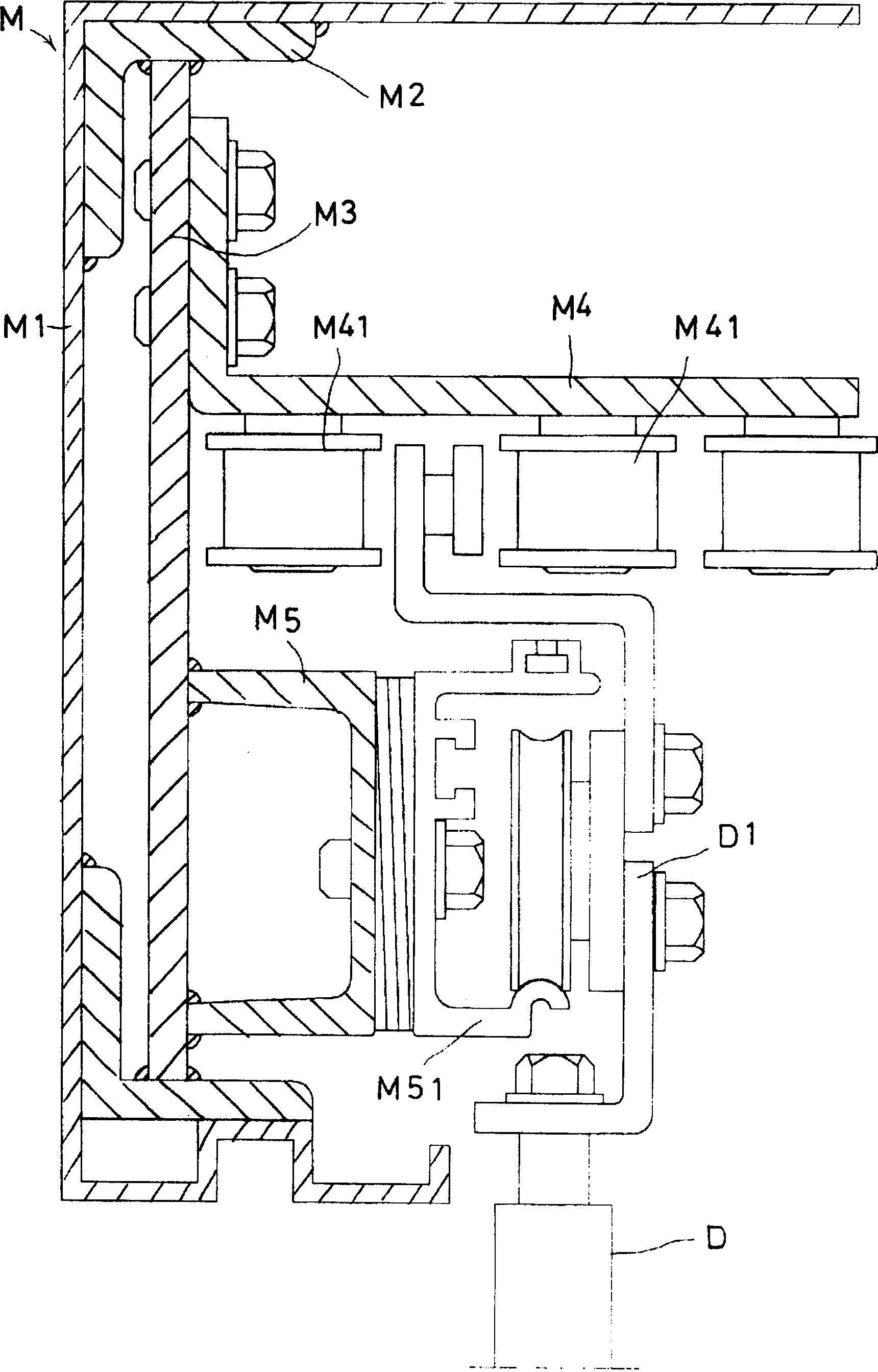

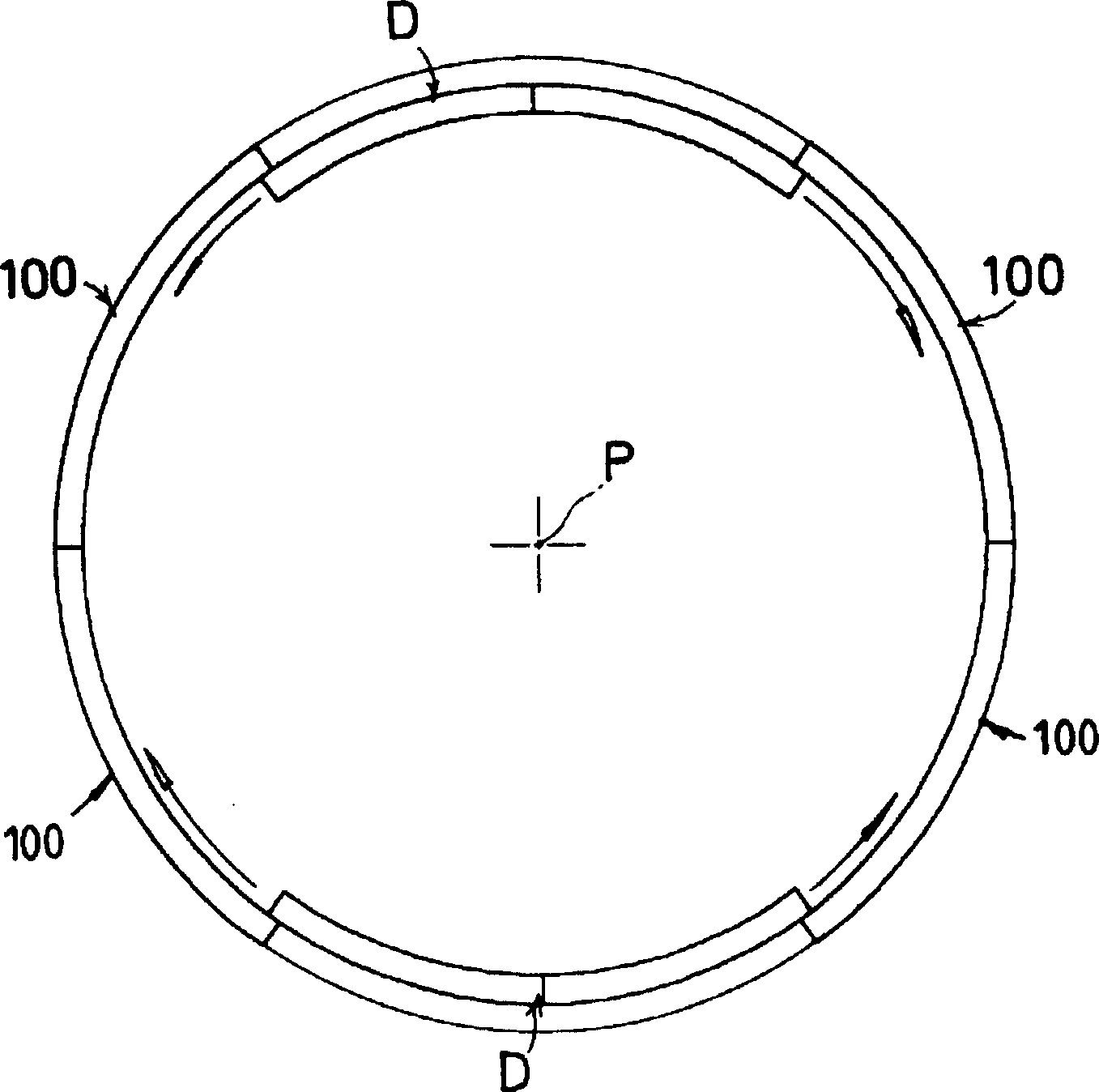

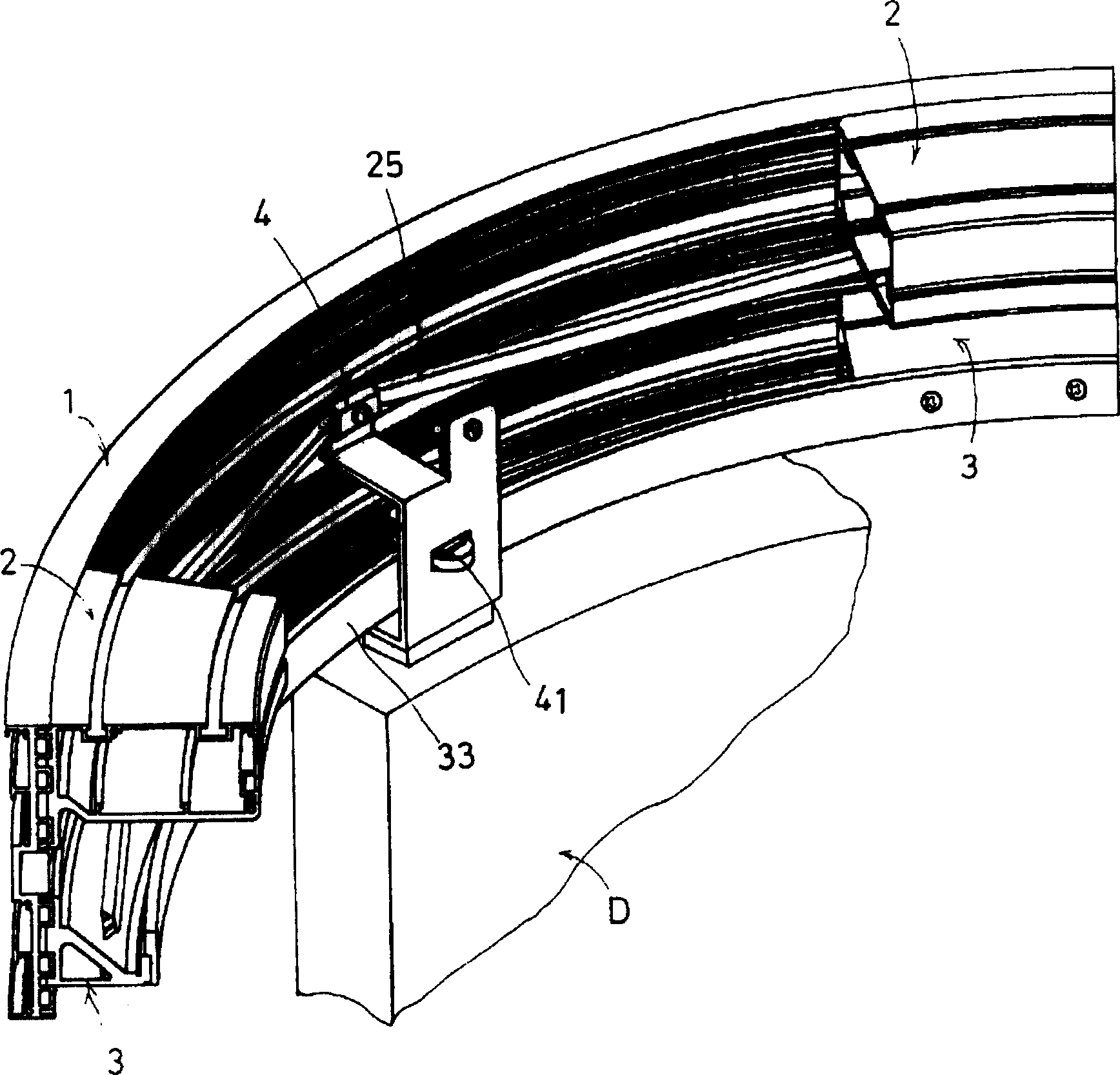

[0033] With reference to the accompanying drawings and preferred embodiments, the specific structure, features and effects of the concentric modular arc type automatic door proposed in accordance with the present invention will be described in detail below.

[0034] See Figure 2 to Figure 9As shown, the concentric modular arc type automatic door 100 of the present invention mainly includes a main frame body 1, a plurality of upper frame seats 2 and a plurality of lower frame seats 3. The main frame body 1 is curved in an arc shape, and most The upper frame seats 2 are evenly distributed and fixed on the inner upper section of the main frame body 1, and most of the lower frame seats 3 are evenly distributed and fixed on the inner lower section of the main frame body 1. The outer panel surface is formed with the same curvature as the inner panel surface of the main frame body 1, so as to fit the inner side of the main frame body 1, so that each upper frame seat 2 and lower frame sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com