Automobile engine cover outer plate forming die

A technology for automobile engines and forming molds, which is applied in the direction of forming tools, engine components, mechanical equipment, etc. It can solve the problems of high difficulty, complex mold structure, and high position accuracy of flanged sliders, so as to increase production rate and stabilize the moving path Accurate, engine cover outer panel flanging forming quality stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

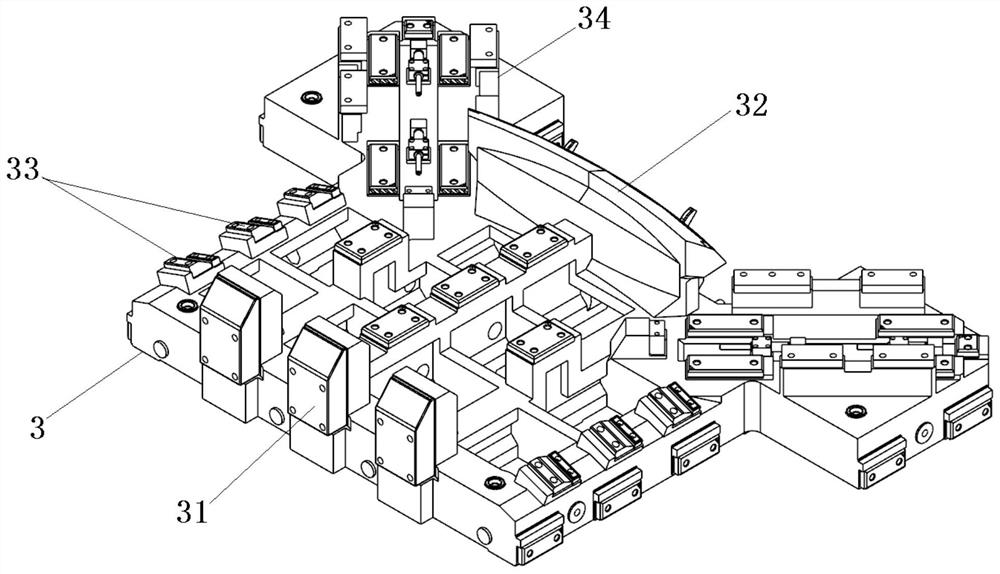

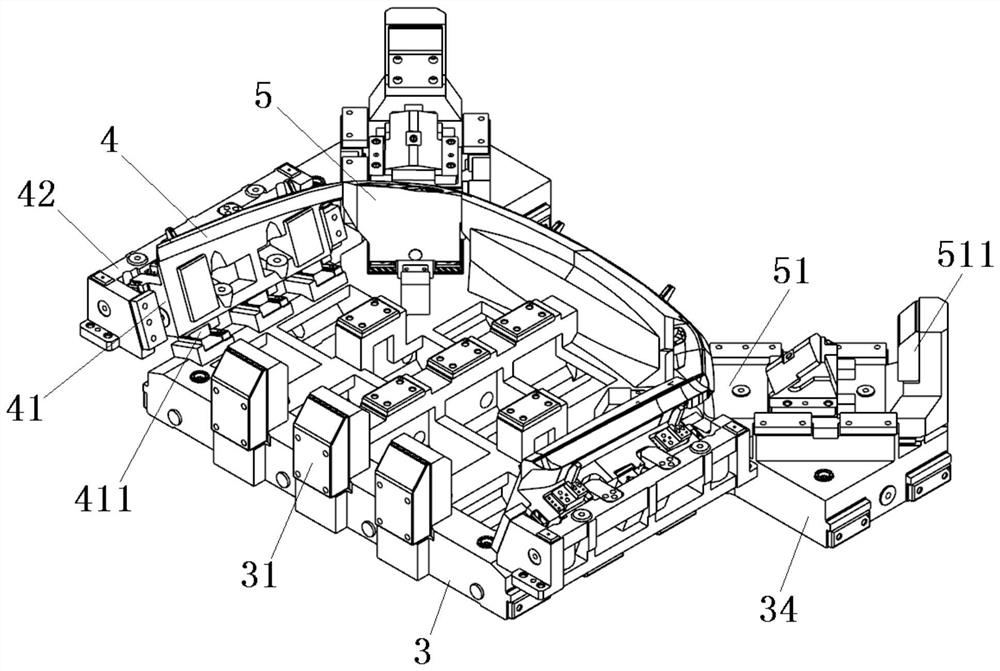

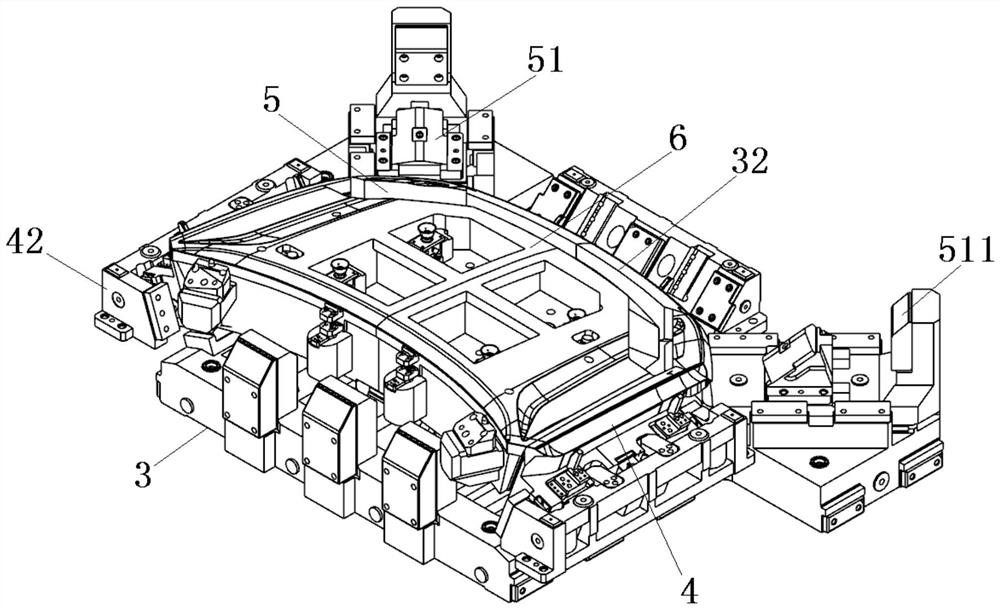

[0039] The specific embodiment of the present invention is as Figure 1-5As shown, a molding die for an automobile engine cover outer panel includes an upper mold base 1 and a lower mold base 2 . The upper surface of the lower mold base 2 is provided with a pulley 3 that can move horizontally forward. This tackle 3 becomes inverted " product " font, and both sides are all provided with guide sliding surface, are placed in the concave cavity of lower mold base 1 and move. The upper surface of the front end of the tackle 3 is provided with a front end molding 32 . Above both side edges of the tackle 3 are all provided with side edge moldings 4 that rise as the tackle 3 advances. The edge of the tackle 3 between the front end forming part 32 and the side forming part 4 is connected with a hypotenuse slider mounting seat 34, and the upper surface of the hypotenuse slider mounting seat 34 is provided with a hypotenuse molding that can move horizontally away from the side of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com