A two-way separation device for walnut shell kernel drum

A technology of two-way separation and separation of shell and kernel, applied in wet separation, solid separation, shelling and other directions, can solve the problems of general effect, large investment, low efficiency of artificial shell-breaking separation, etc., to improve the degree of automation, two-way non-destructive separation , reduce the effect of manual selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

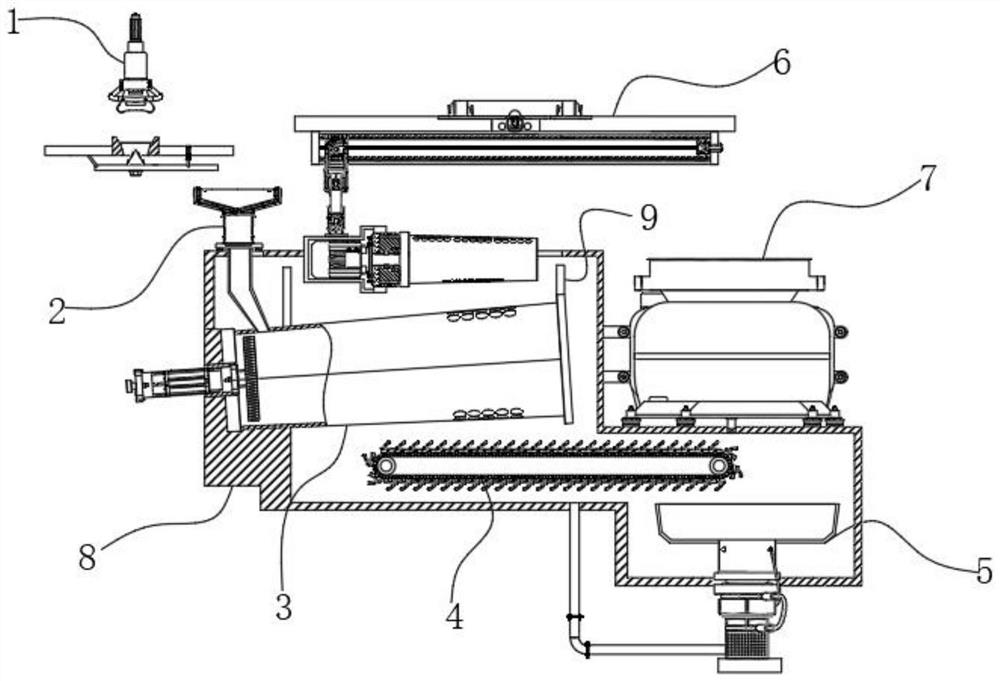

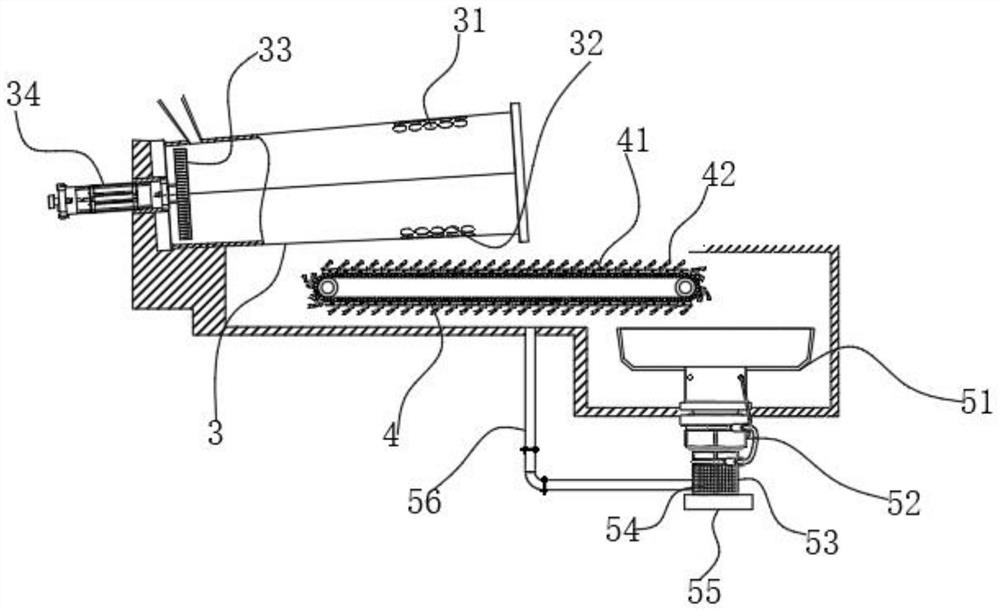

[0038] see Figure 1~4 , in an embodiment of the present invention, a two-way separation device for a walnut shell and kernel drum, comprising:

[0039] The broken shell assembly 1 is used to continuously crack the walnuts;

[0040] The feeding port 2 is used to receive the shell kernel mixture from the discharge end of the shell breaking assembly 1;

[0041] The shell and kernel separation cylinder 3 is fixedly embedded in the processing bin 8, and the two ends of the shell and kernel separation cylinder 3 are closed, one end of the shell and kernel separation cylinder 3 is connected with the feeding port 2, and the upper position of the other end is A plurality of first separation holes 31 are provided, and a plurality of second separation holes 32 are provided in the lower position, and the processing bin 8 is filled with separated water that does not exceed the separation cylinder 3; and

[0042] The walnut kernel collecting component 6 is used to collect the walnut kern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com