Sealing performance inspection unit for soft bag packaging system, and inspection method

A packaging system and inspection unit technology, applied in fluid tightness testing, liquid tightness measurement using liquid/vacuum degree, measuring device, etc., can solve the problem of cumbersome opening of the top cover, low degree of automation, and unfavorable flexible packaging bags Sealing detection and other issues to achieve the effect of improving sealing, improving work efficiency, and facilitating installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

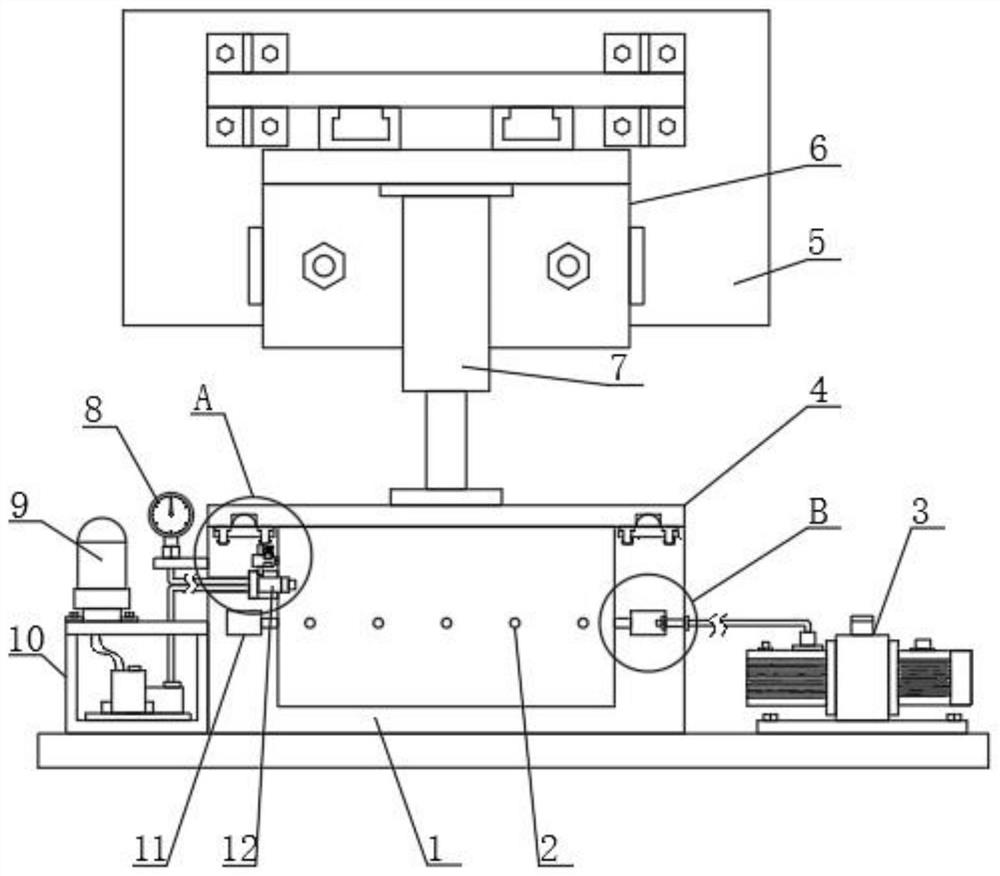

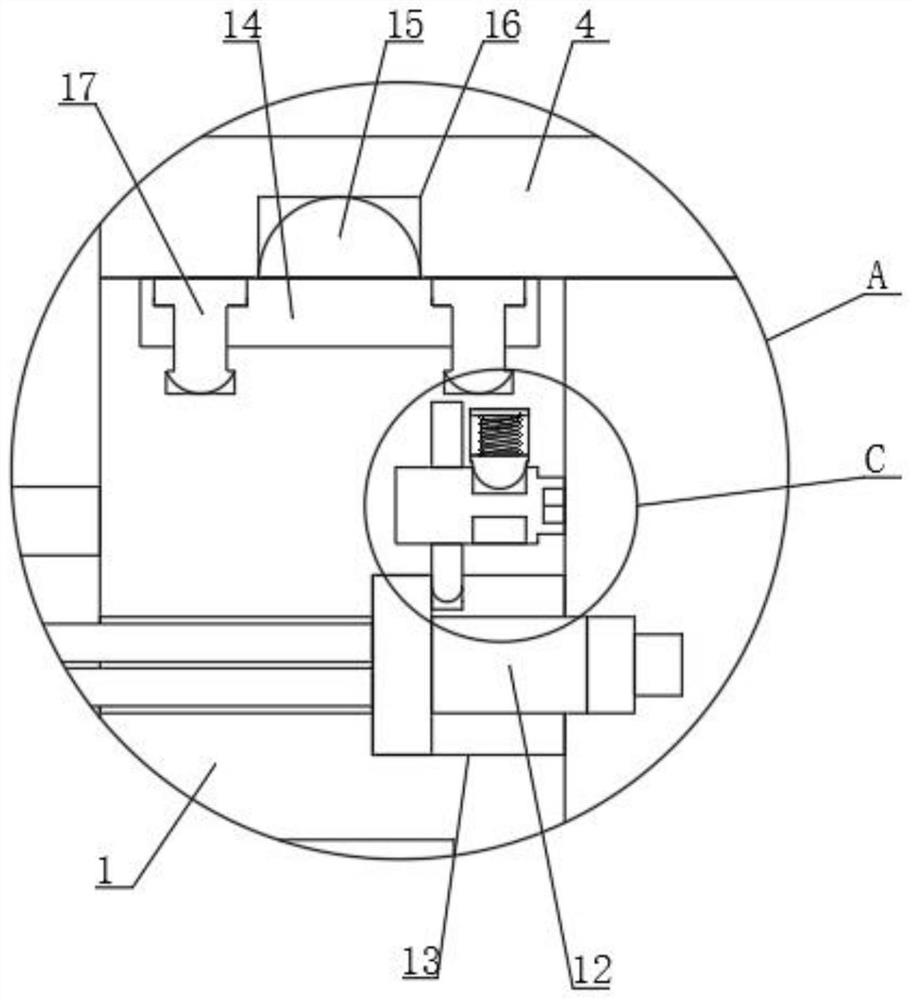

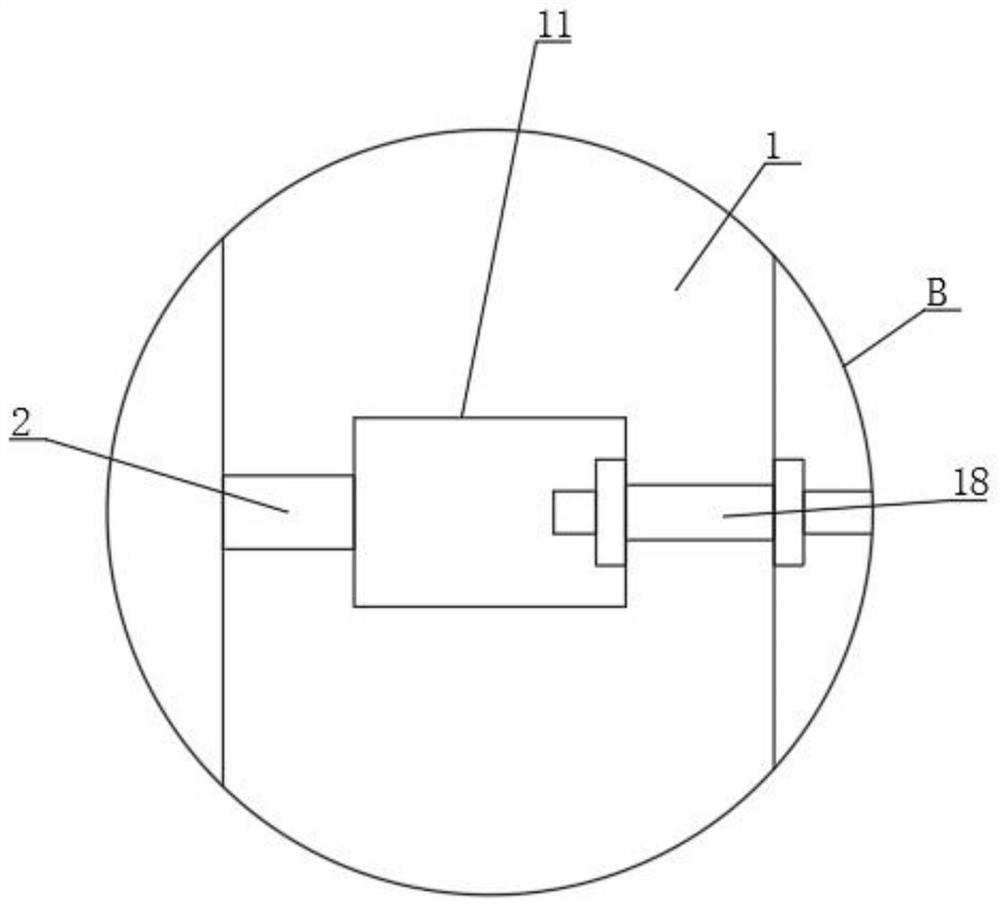

[0028] see Figure 1 to Figure 5 , the present invention provides a technical solution: a sealing inspection unit for a soft bag packaging system, including a detection tank 1, a vacuum pump 3, a top cover 4, a pressure sensor 12, a pressure gauge 8 and an alarm system, and the vacuum pump 3 is set at the detection On one side of the tank 1, the top cover 4 is arranged on the top of the detection tank 1, the pressure gauge 8 is fixed on one side of the detection tank 1, and the pressure gauge 8 is connected to the pressure sensor 12 through a connecting line, and the inner wall of one side of the detection tank 1 is opened There is an installation groove 13, and the pressure sensor 12 is installed in the installation groove 13, a disassembly structure is provided between the detection groove 1 and the pressure sensor 12, a sealing structure is provided between the top cover 4 and the detection groove 1, and the alarm system includes data processing Module, data receiving modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com