Carbon plate resistance value automatic test classifier

An automatic testing and sorting machine technology, applied in the direction of vibrating conveyor, sorting, conveyor, etc., can solve the problem of low detection efficiency, and achieve the effect of high production efficiency, rapid automatic production, and automatic production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

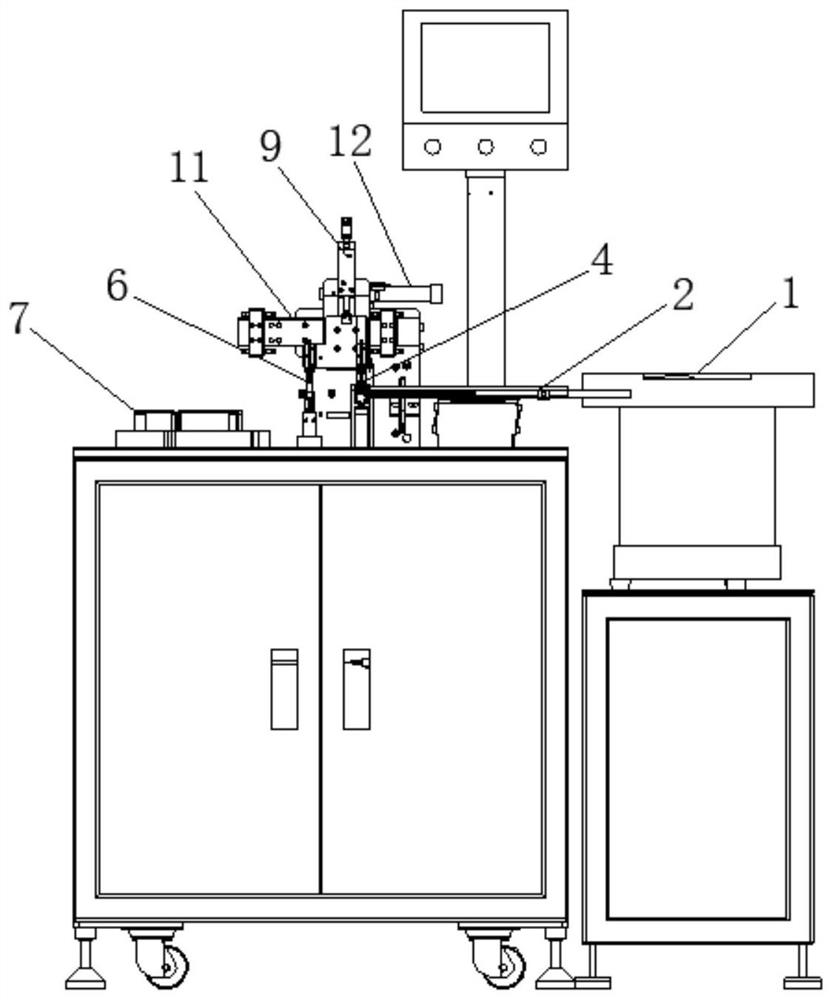

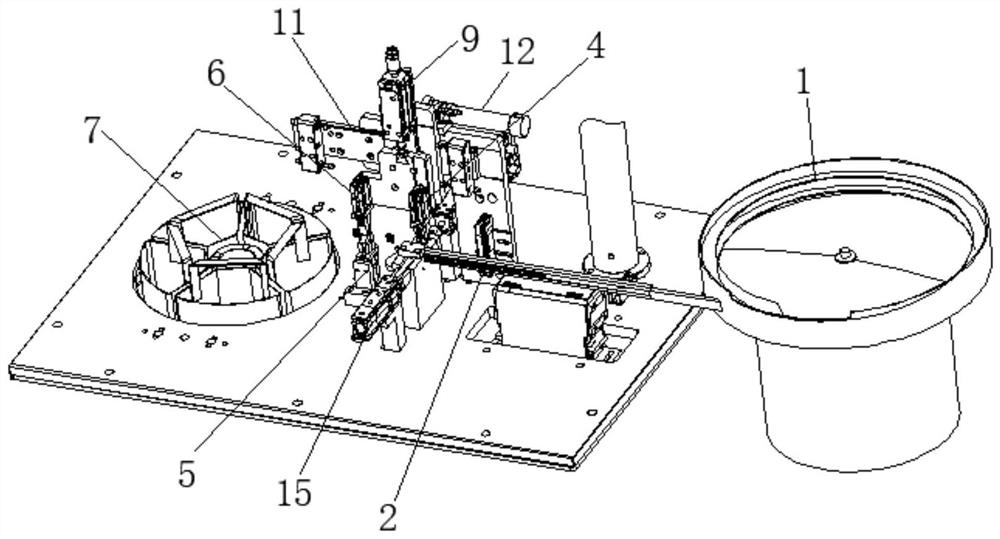

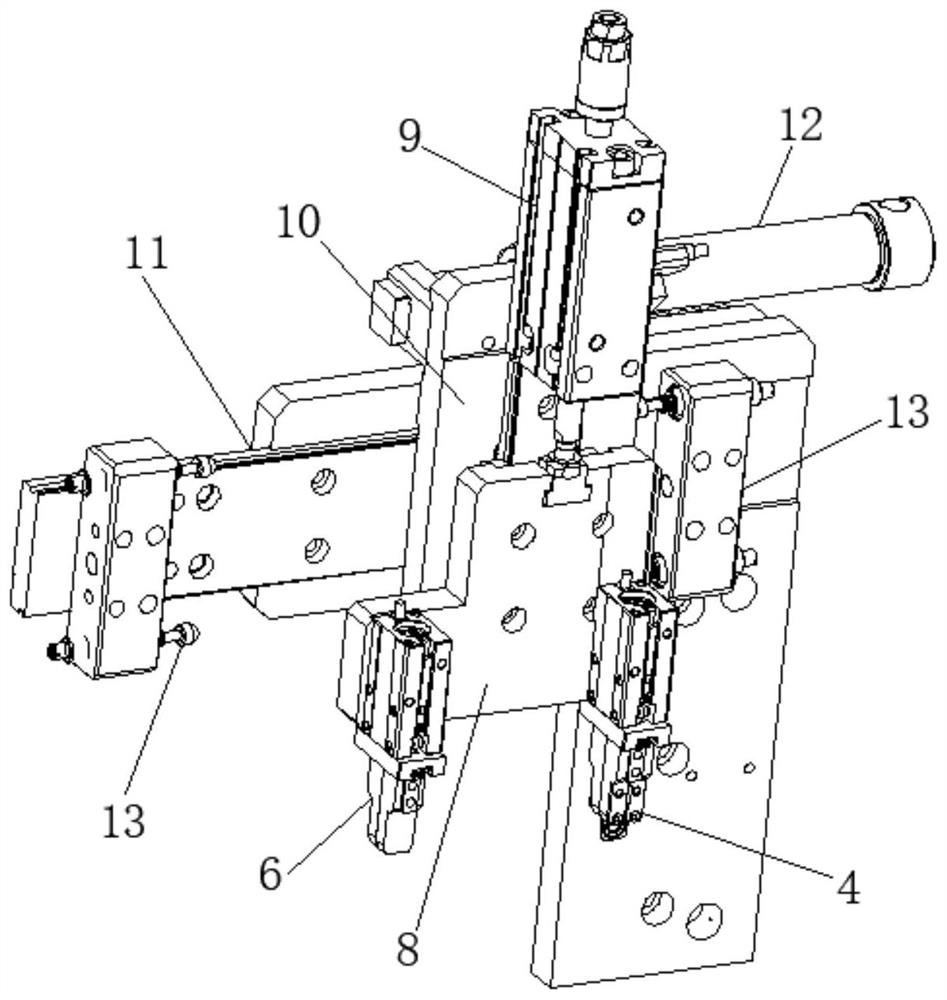

[0022] See figure 1 —— Figure 8 , the automatic testing and sorting machine for carbon sheet resistance of the present invention comprises a table top on which a feed rail 2, a detection seat 3, and a packing bucket 7 are horizontally installed, and the feed rail 2 is positioned at the side of the detection seat 3, and above the detection seat 3 The test jig arm 4 that can move along the X, Y, and Z axes is installed, and the clamping position of the test jig arm 4 is equipped with a detection pressure column 14 for detection. The detection pressure column 14 is connected to the detection controller, and the detection controller has a display Screen, feeding track 2 is connected to vibrating plate 1, and vibrating plate 1 is positioned at the side of table top, and feeding track 2 is vertically installed, and carbon sheet 23 is fed vertically.

[0023] A transfer cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com