Electrical installation pre-embedded wire pipe protection device for energy-saving building

A technology for electrical installation and protection devices, which is applied in the field of building construction, can solve problems such as insufficient protection, reduced protective performance of protective devices, and cracks at the joints of wire pipes, so as to shorten the impact time and reduce the impact. effect, the effect of high-efficiency protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

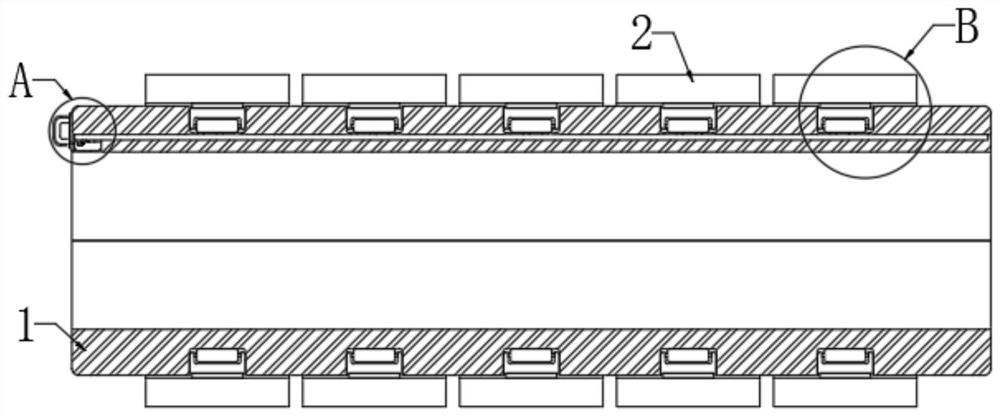

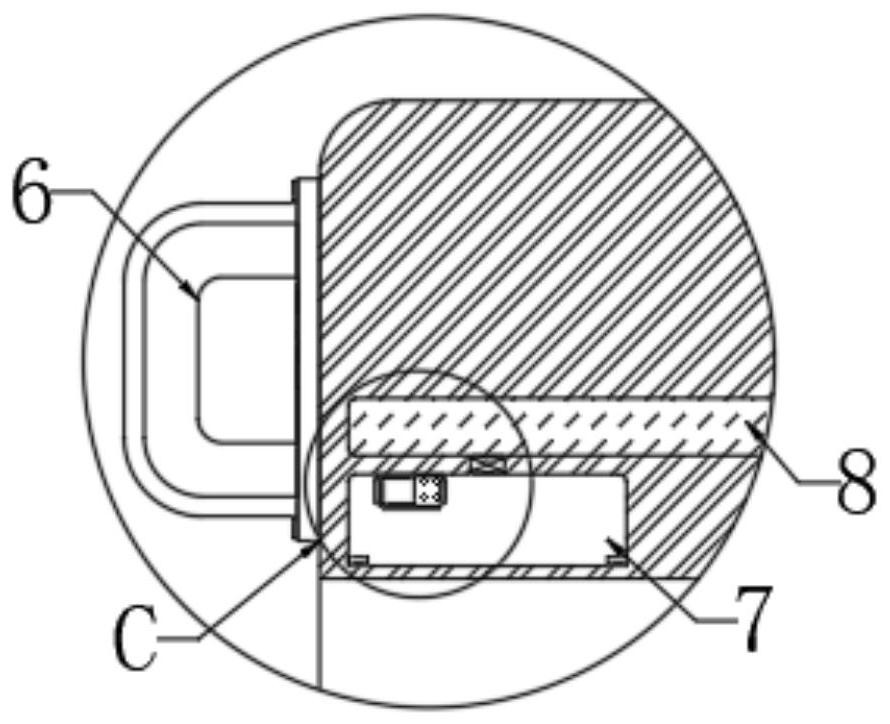

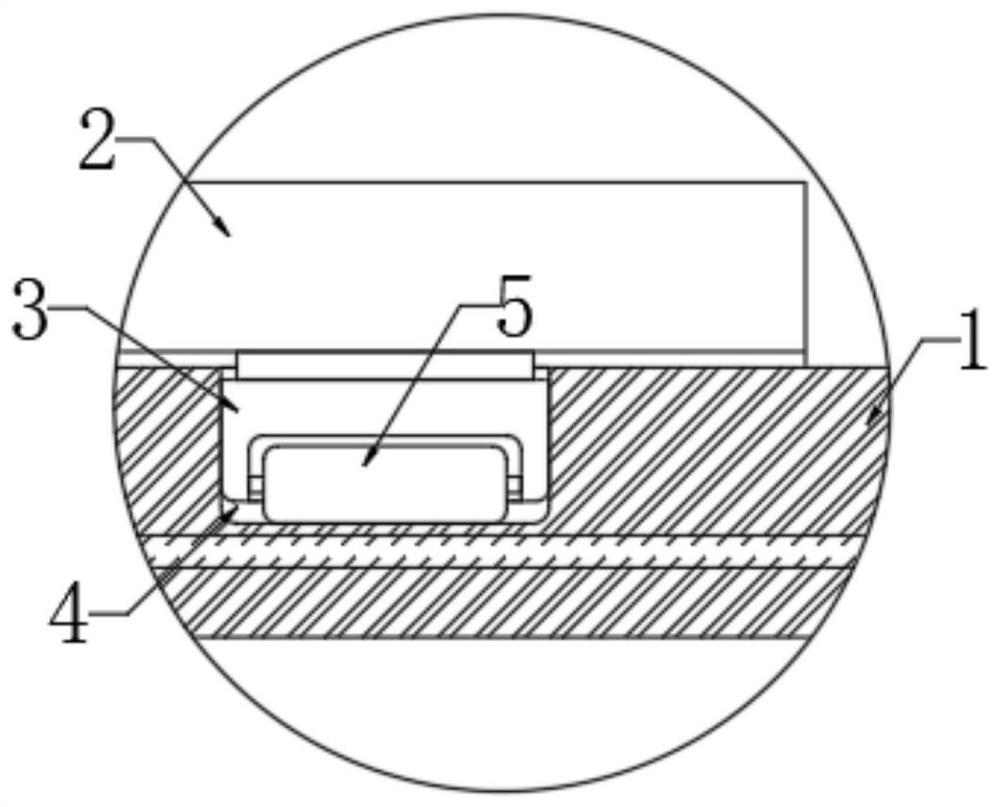

[0031] Refer Figure 1-7 A electrically mounting of electrical mounting tube protection means for energy-saving buildings, including two semi-tube bodies 1, uniformly disposed on both semi-tube body 1, and protects for pre-buried tubes Therefore, each half-loop slide 4 is provided with a protective module for protection, and the protective module includes a semi-annular protective ring 2 disposed on each of the half-loop slide 4, each of which is fixed inner side of each of the semi-annicy-shaped shear 2. Connecting an arcuate connection block 3, each curved connection block 3 is away from the side of the corresponding semi-annular shear 2, and the roller 5 is mounted;

[0032] In order to connect two corresponding semi-ring protective ring 2, each of the half-loop shelter 2 is connected to each of the above-lowering semi-annular sheath 2, the connection module includes a semi-annular shape located below. The two connecting grooves 13 in the upper end of the protective ring 2 are f...

Embodiment 2

[0039] Refer Figure 8-10 The present embodiment differs from the first embodiment in that each of the half-loop shelter is provided with a curved chamber 16, and each curved chamber 16 is provided with a sliding mesh plate 24 for sliding, each The semi-ring protective ring 2 is equipped with a placement chamber 19, and each placed chamber 19 is placed, and the expandable ball 21 is placed, the expansion ball 21 is a spherical bladder, and the inner filled with impact expansion material, the expansion material is azide sodium. Sodium azide is rapidly decomposed into a large amount of nitrogen, and the chemical equation of the reaction is as follows: 2naNan 3 ==== 2NA + 3N 2 (Gas), each of the placing cavities 19 communicate with the corresponding arc chamber 16 through the opening 20, each sliding mesh plate 24 is elastically connected by the spring 22 and the inner wall of the corresponding arc chamber 16, each sliding mesh board 24 Near the side of the corresponding placement cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com