Insulator top pre-twisted binding wire bending device and method for manufacturing bent binding wire

An insulator and pre-twisted technology, applied in the direction of insulators, overhead lines/cable equipment, electrical components, etc., can solve the problems that affect the fixing effect of cables and insulators, are not easy to bend pre-twisted wires, and are difficult to fit insulators, etc. , to achieve the effect of reducing the construction burden, ensuring the firmness of the connection, and ensuring the quality of the construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

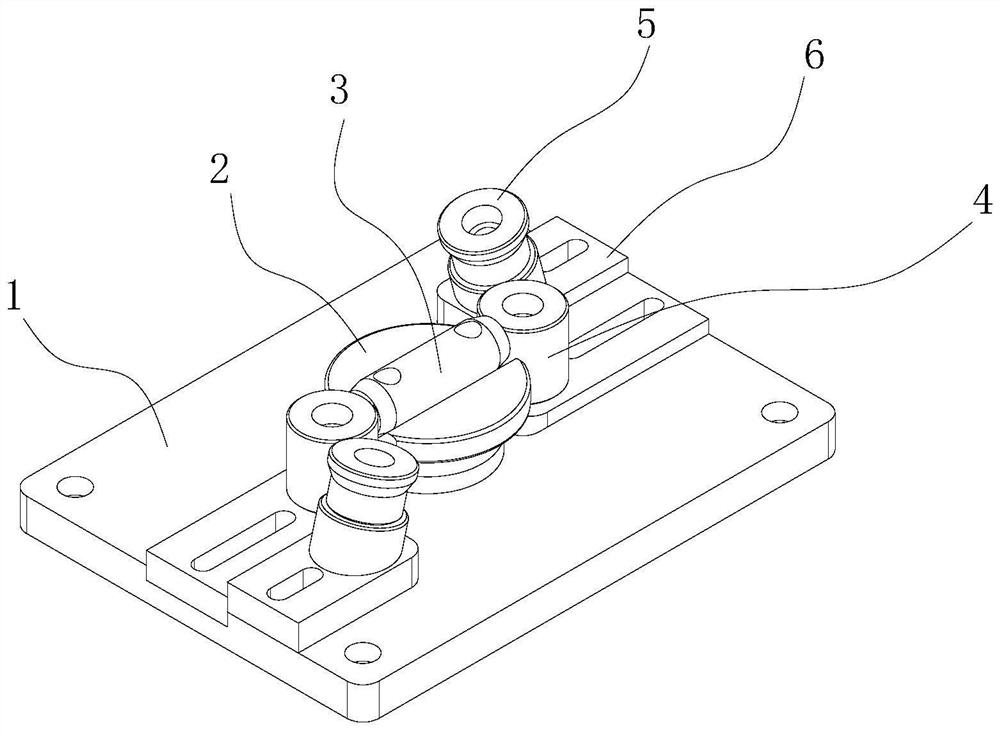

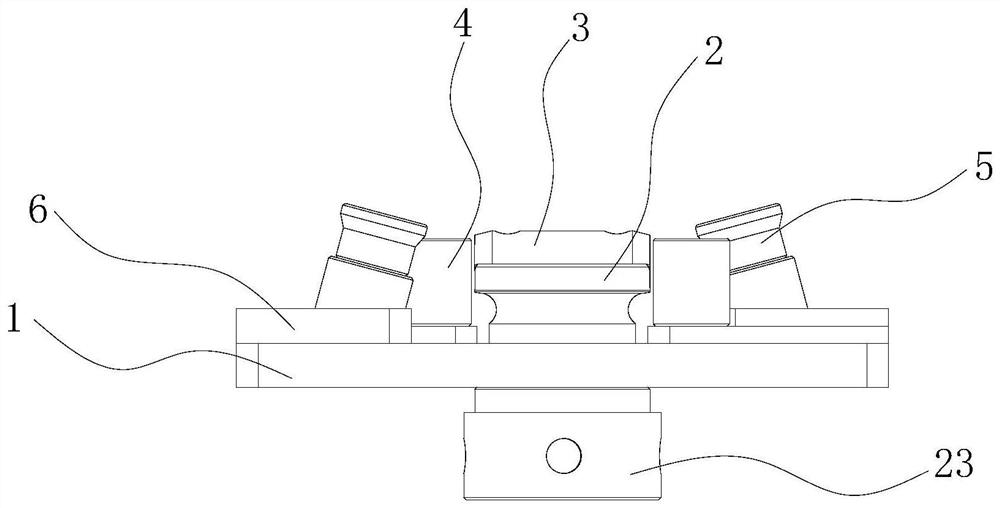

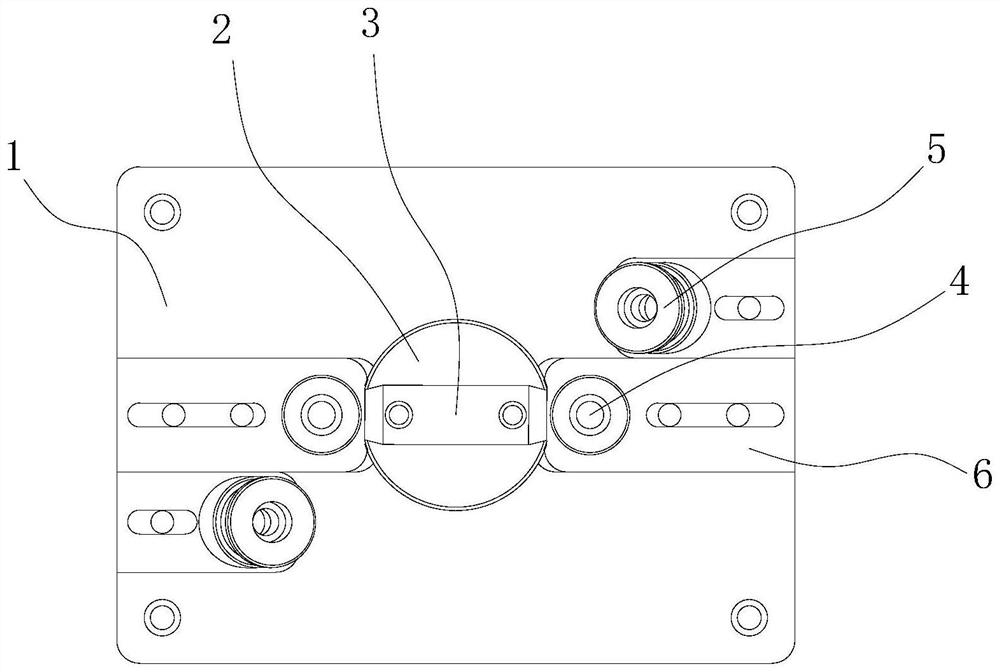

[0035] The following is attached Figure 1-9 To further illustrate the present invention, the present invention includes a mold base 1, a forming column 2, a mandrel 3, a pair of idler wheels 4 and a pair of positioning wheels 5;

[0036] The mold base 1 has a central hole, and the forming column 2 is provided with an upper profiling section on the top of the insulator and a pivoting section in the middle. The pivoting section extends into the central hole of the mold base 1 and rotates freely relative to the central hole; The section includes a top platform, an arc groove 21 and a V-shaped groove 22 provided on the top surface of the top platform. The mandrel 3 is horizontally accommodated in the V-shaped groove 22, and the size of the mandrel 3 is shaped like the diameter of the cable 8;

[0037] Two rollers 4 are symmetrically arranged on both sides of the forming column 2, the distance between the rollers 4 and the forming column 2 is greater than the diameter of the pre-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com