Device for replacing oil well mouth back pressure valve for oil exploitation

A technology for oil exploitation and oil wells, which is used in the field of back pressure valve replacement, which can solve the problems of screwing out nuts and troublesome valve replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

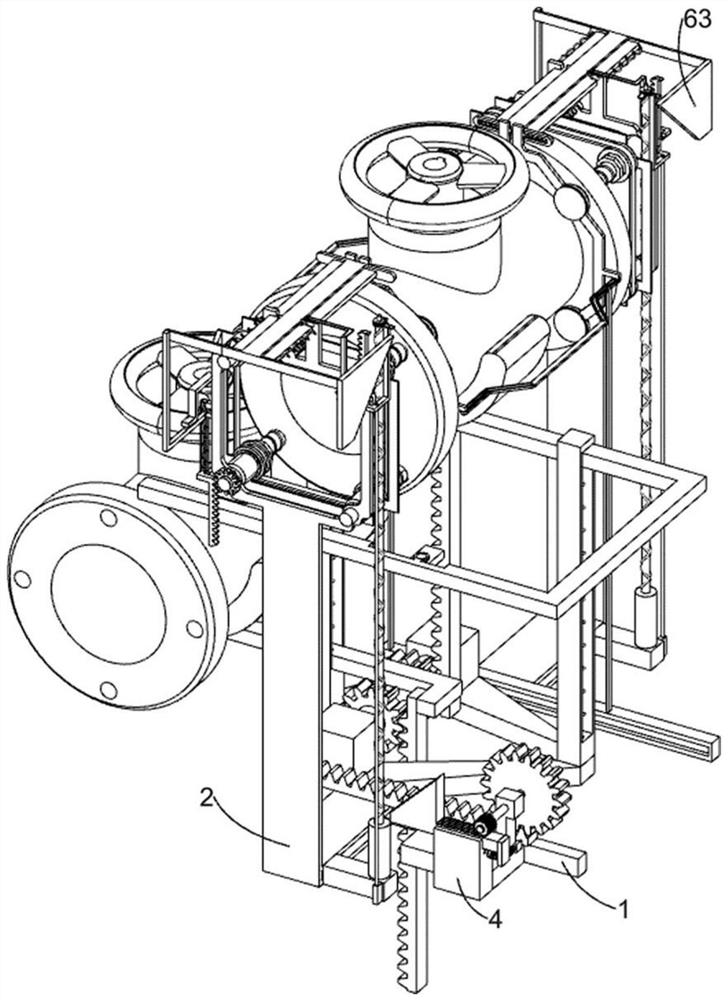

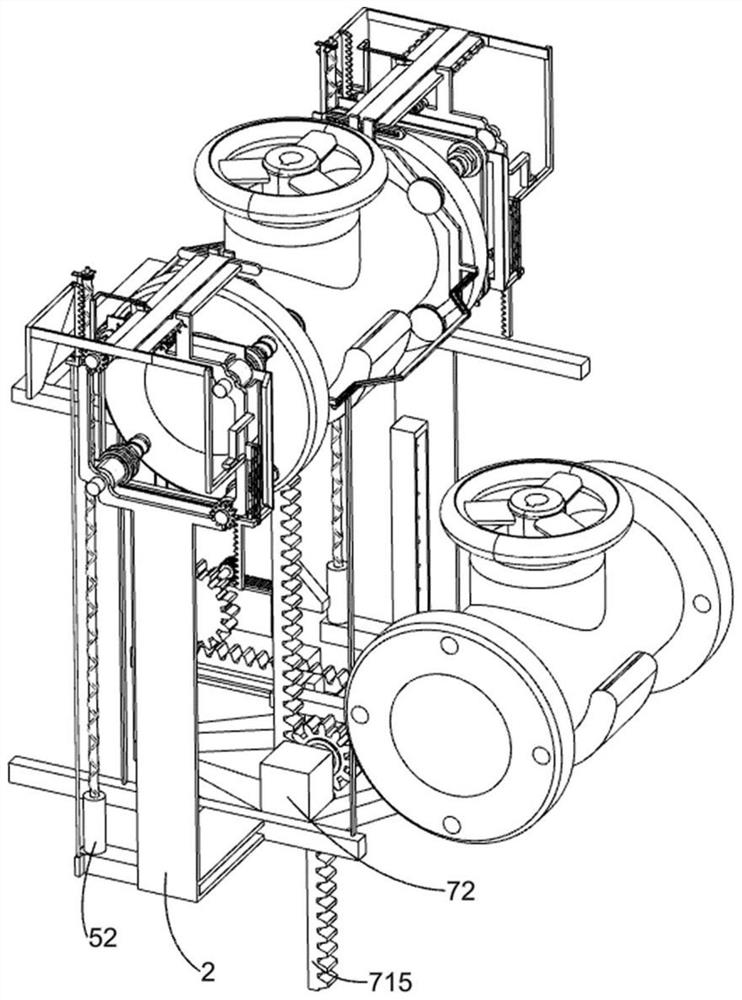

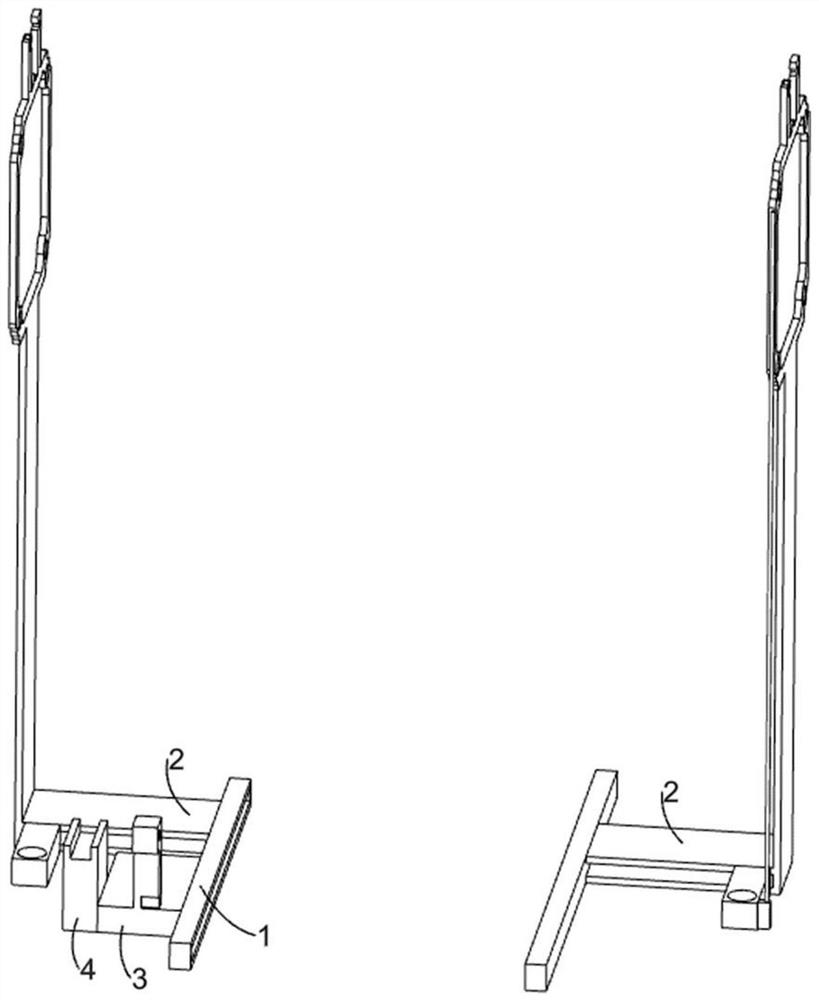

[0030] Embodiment: A kind of equipment that is used for the replacement of oil well head back pressure valve in oil exploitation, such as Figure 1-14 As shown, it includes a slotted slide rail base 1, a special-shaped slotted sliding support frame 2, a slotted opening frame 3, a slotted sliding frame 4, a reciprocating drive mechanism 5, a pushing mechanism 6, a pressing mechanism 7 and a moving mechanism 8 , two slotted slide rail bases 1 are set opposite to each other, a special-shaped slotted sliding support frame 2 is fixedly installed on the slotted slide rail base 1, and the slotted and holed frame 3 is welded on one of the slotted slide rail bases 1, and the slotted slide Frame 4 is fixedly connected on the slotted hole frame 3, and the reciprocating drive mechanism 5 is arranged on the special-shaped slotted sliding support frame 2, and the ejection mechanism 6 is also arranged on the special-shaped slotted sliding support frame 2, and the ejection mechanism 6 is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com