Cluster type down-the-hole hammer

A down-the-hole hammer and cluster technology, which is used in drilling equipment, wellbore/well components, earth-moving drilling, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

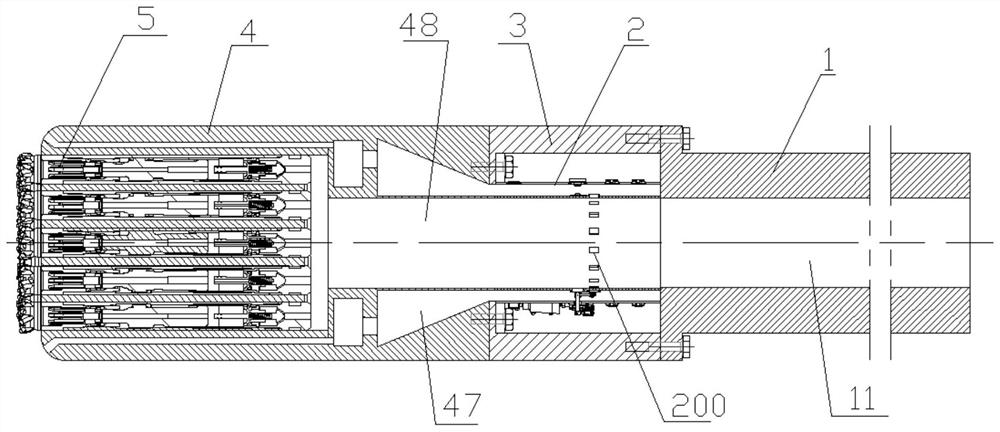

[0033] Such as Figure 1 to Figure 9 , a cluster type down-the-hole hammer of the present invention includes a drill pipe 1 and a down-the-hole hammer connected to the drill pipe. 11 is connected with the high-pressure gas chamber 48, and the high-pressure gas in the main air inlet 11 enters the high-pressure gas chamber 48, and makes the down-the-hole hammer act.

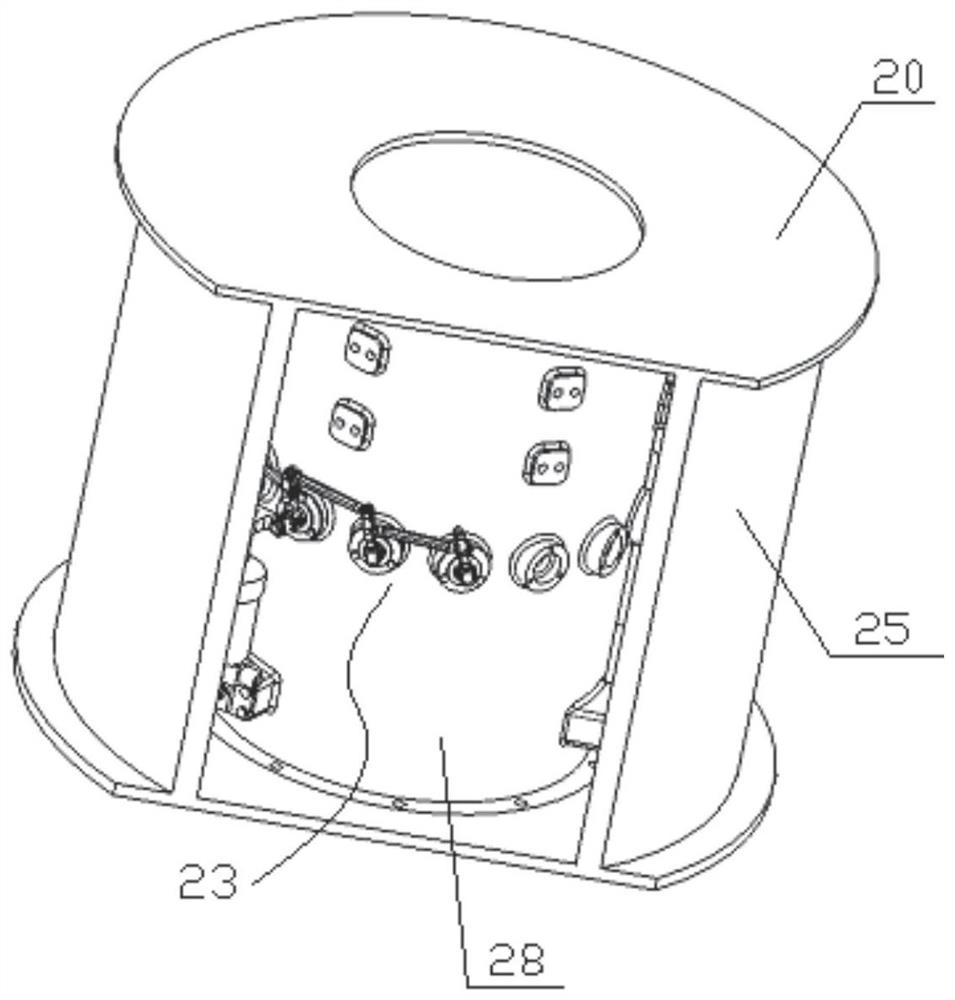

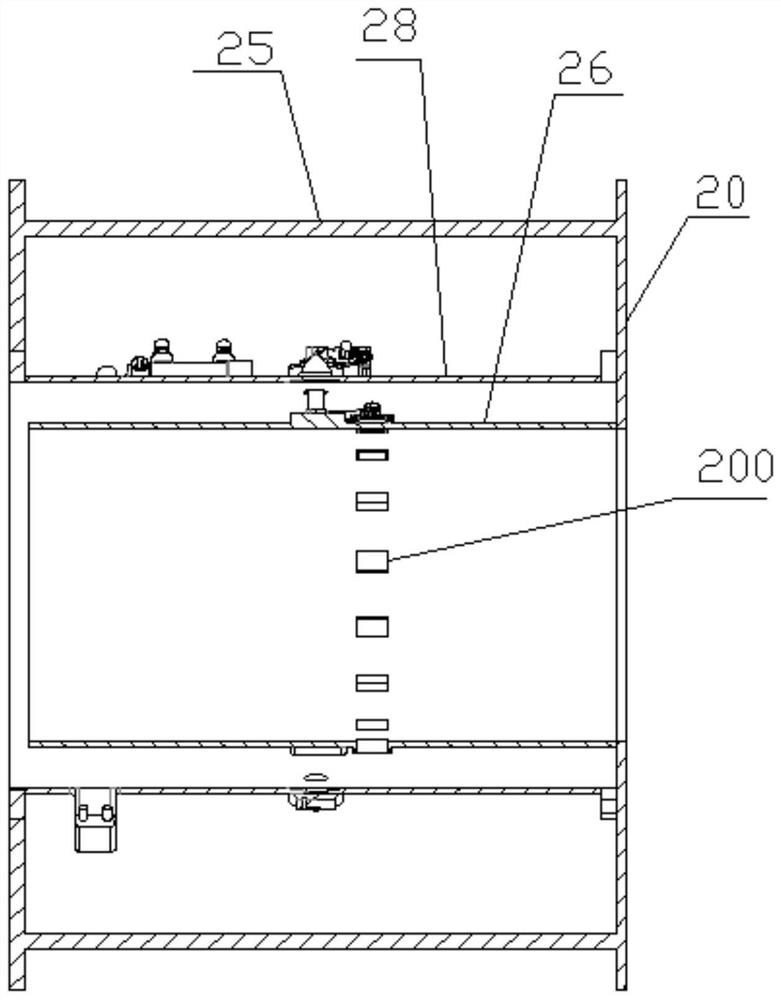

[0034] In order to regulate the airflow coming out of the main air inlet 11, the present invention arranges an airflow regulating valve 2 between the drill pipe 1 and the down-the-hole hammer, and the airflow regulating valve 2 is provided with a valve plate 24 and an airflow regulating hole 200, and the valve plate 24 Close the airflow regulating hole 200, the air inlet of the airflow regulating valve 2 is connected with the main air inlet 11, and the air outlet is connected with the high pressure air cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com