Foldable assembly type assembly jig frame and construction method thereof

A prefabricated and tire frame technology, which is applied in the field preparation and construction of pillars and building components, can solve the problems of low steel reuse rate, low erection efficiency, and inconvenient construction, so as to improve erection efficiency and reduce hoisting The effect of small workload and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

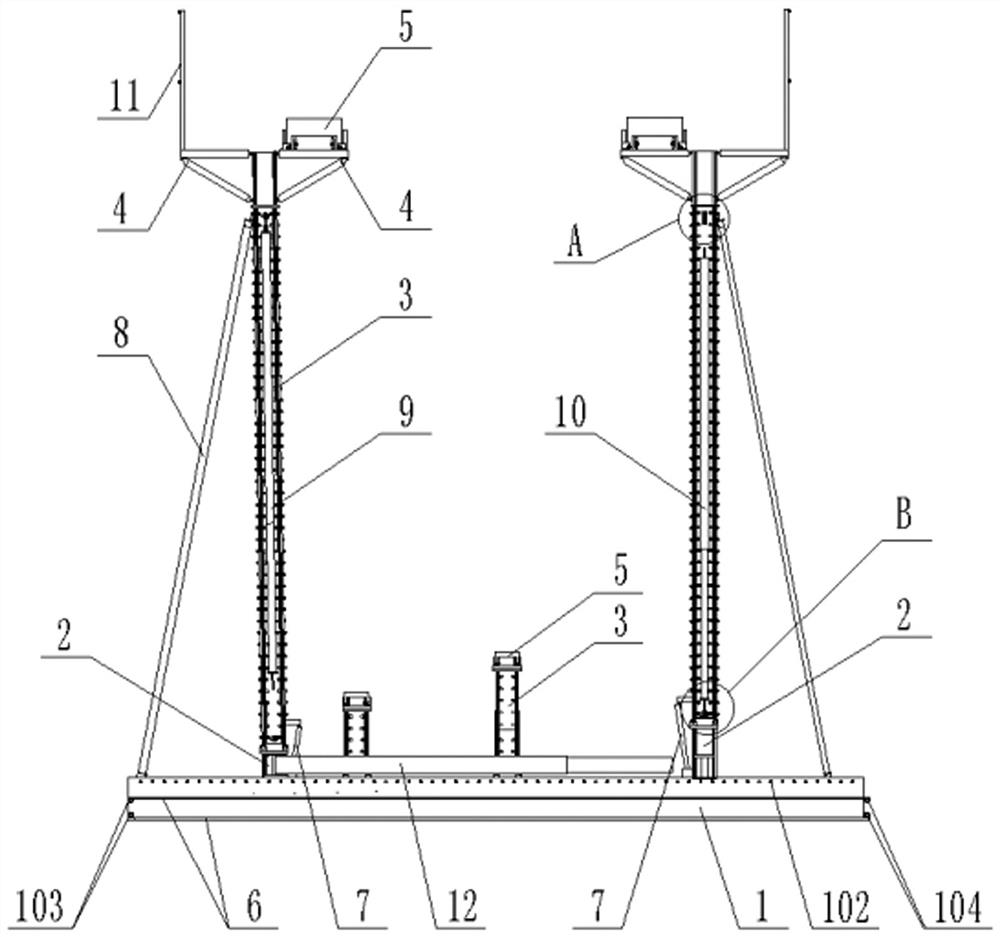

[0048] This embodiment provides a foldable assembled tire frame, please refer to figure 1 , including a bottom beam 1, a trolley 2, a column 3, a support frame 4 and a supporting member 5.

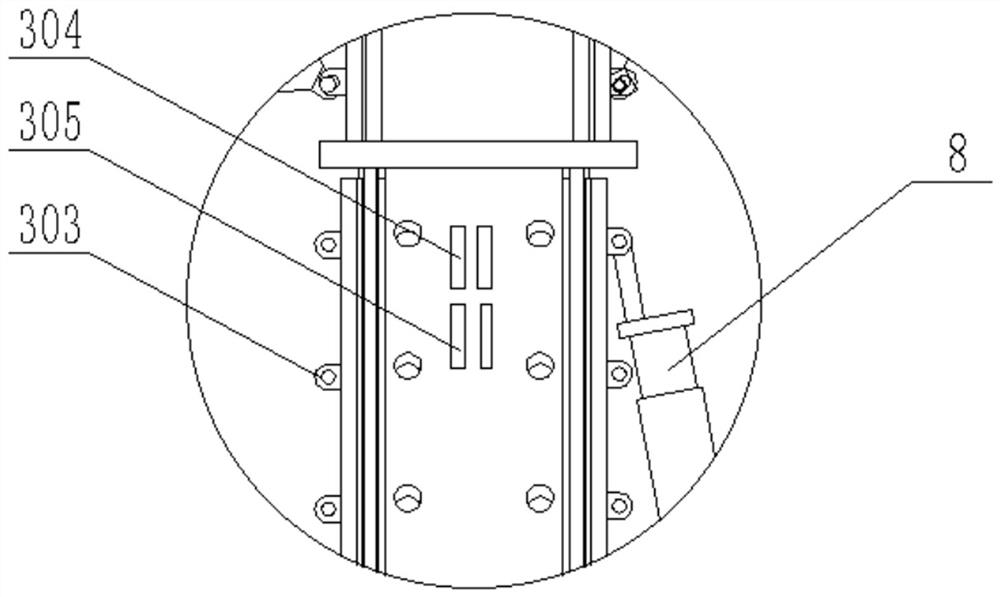

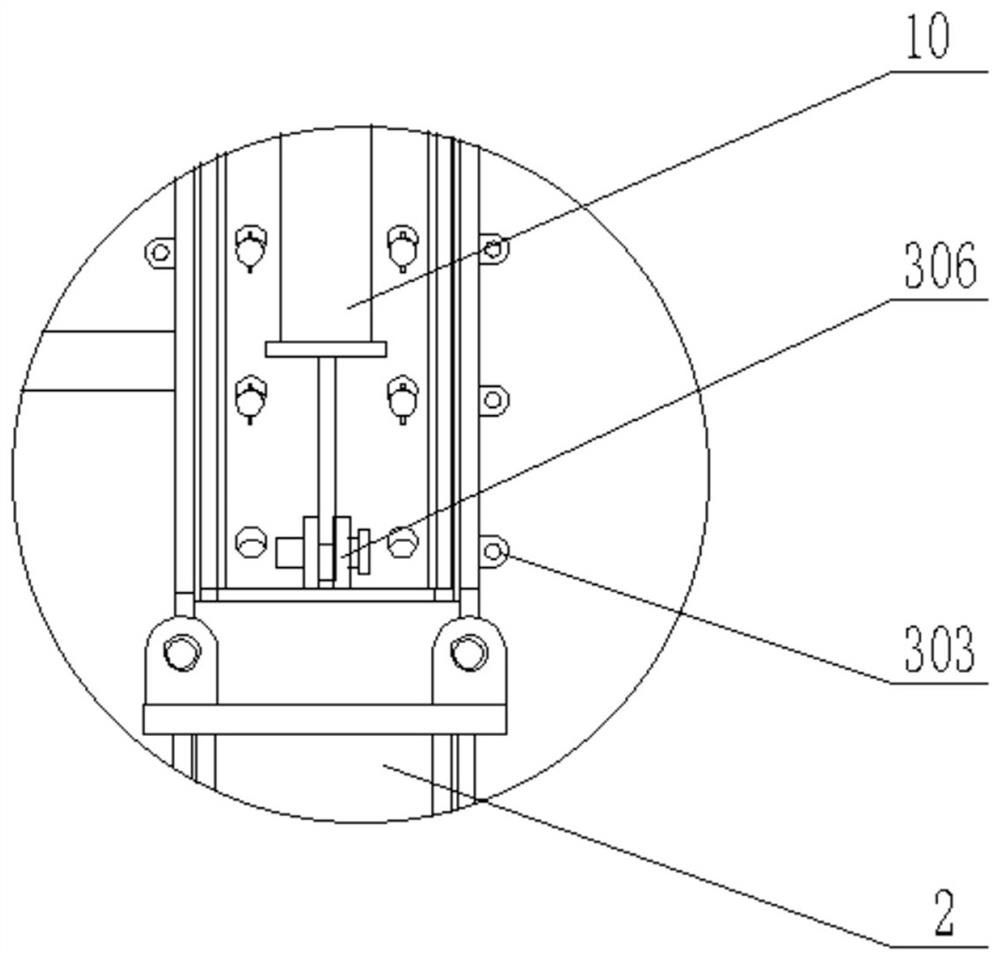

[0049] see Figure 4 , Figure 5 with Image 6 , the bottom beam 1 includes two horizontal beams and two vertical beams. On both sides of the structure, the upper end of the vertical beam plate is higher than the upper horizontal beam plate, the upper horizontal beam plate and two vertical beam plates form an H-shaped structure, and the lower horizontal beam plate is located at the lower end of the H-shaped mechanism . In order to increase the contact area with the ground and reduce settlement, one upper and one lower flange plates 6 are respectively arranged on the outer walls of the two vertical beams, and the lower end surface of the lower flange plate 6 is in contact with the bottom beam 1 The lower end is even. The two vertical beams are located above the upper horizontal beam, ...

Embodiment 2

[0059] This embodiment provides a construction method for a foldable assembled tire frame, which includes the following steps:

[0060] S1. Arrange the folded tire frames according to the layout direction of the steel structure to be assembled, which can be arranged in a straight line, in an arc, or in a folded line, etc., such as Figure 11 shown.

[0061] S2, unfold the bottom supports 12 of each tire frame, connect the bottom supports 12 of two adjacent tire frames, so that each tire frame forms a stable structure, such as Figure 12 shown.

[0062] S3, expand column 3, as Figure 13 shown. When the column 3 is unfolded, the expansion power can be provided by the telescopic cylinder 7, which can save more effort.

[0063] S4, connect the first support 9 in the plane and the second support 10 in the plane, so that each tire frame forms a stable system, such as Figure 14 As shown, the two ends of the first support 9 in the plane are respectively connected to the No. 2 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com