Sludge treatment sedimentation tank capable of reducing sludge flocculation

A sludge treatment and sedimentation tank technology, applied in dehydration/drying/concentration sludge treatment, mixer with rotating stirring device, mixer, etc., can solve the problem of unfavorable sewage and violent stirring of chemicals, and unfavorable sludge complete flocculation Precipitation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

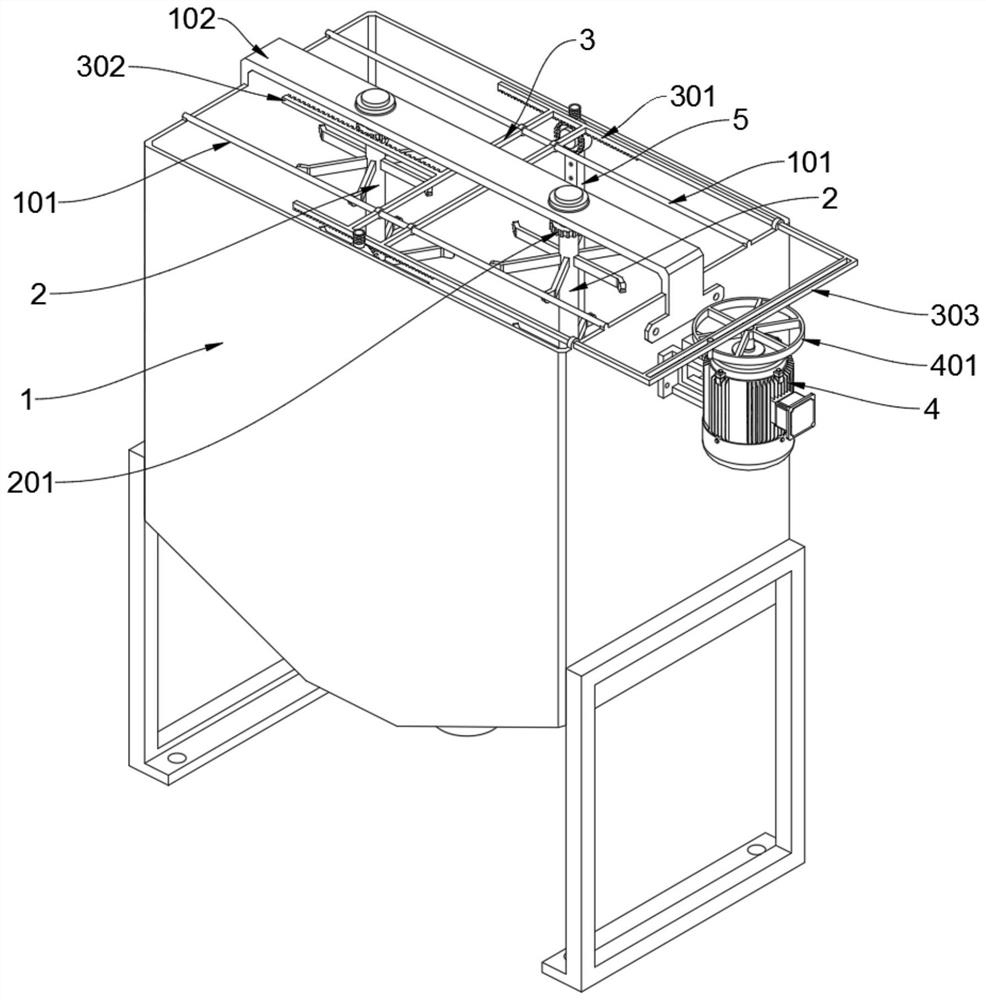

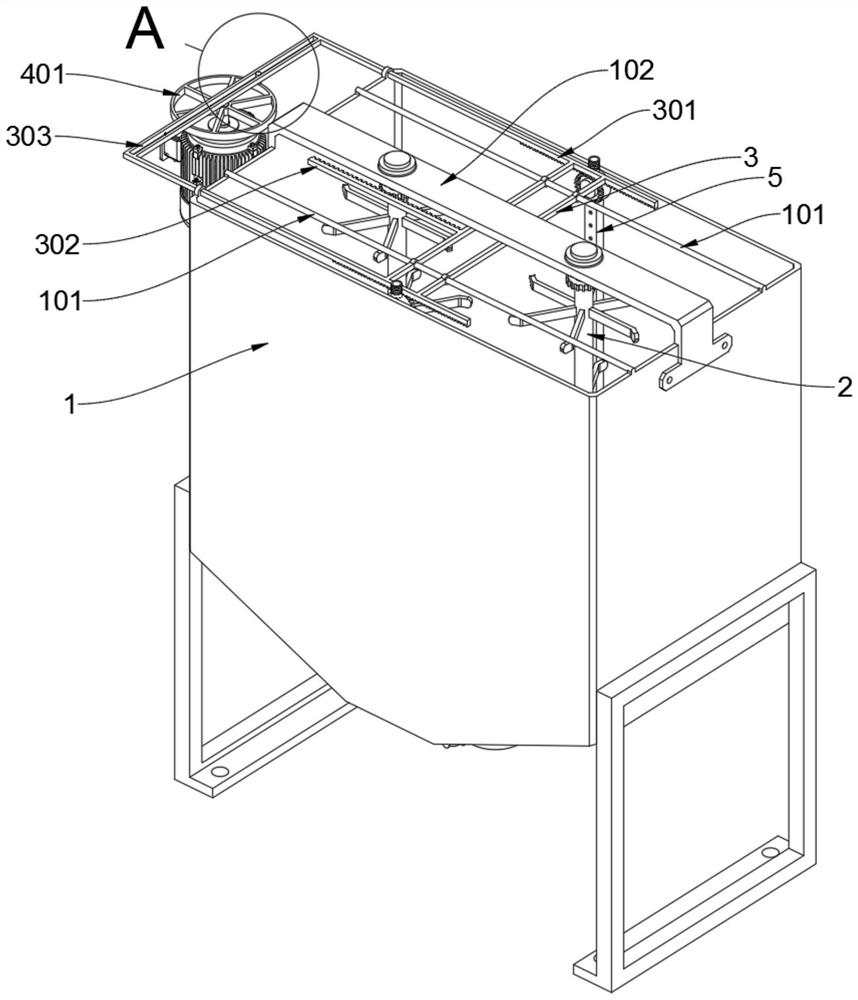

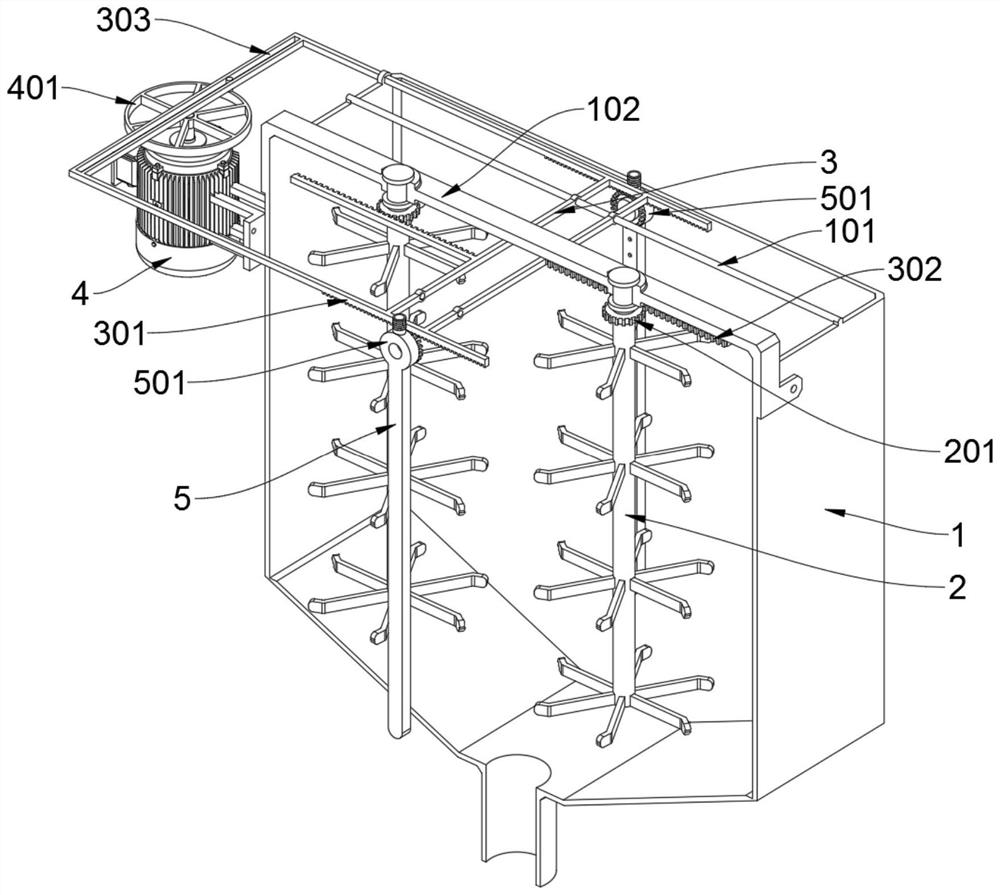

[0030] see Figure 1 to Figure 8 , the present invention provides a sedimentation tank for sludge treatment that can reduce sludge flocculation, including a sedimentation tank 1, the sedimentation tank 1 includes a cross brace positioning shaft 101 and a cross brace installation plate 102, the sedimentation tank 1 has a rectangular structure, and the sedimentation tank 1 There are two cross-brace positioning shafts 101 symmetrically welded on the top opening of the sedimentation tank 1; two flocculant spray parts 5 are symmetrically rotated in the top middle of the inner walls of the front and rear sides of the sedimentation tank 1; The driving mechanism 3; the top position of the outer wall on the right side of the sedimentation tank 1 is provided with a motor 4, a runner 401 is set on the top of the rotating shaft of the motor 4, and a short dial shaft is supported and welded on the outer ring of the runner 401; the runner 401 The short dial shaft on the top corresponds to t...

Embodiment 2

[0039] The inventor found that the flocculation sedimentation tank is placed under the water surface through the pipeline to discharge the flocculation mixed water and drive the water flow to mix. When working for a long time, it is easy to cause the spray hole on the flocculant spray part 5 to be blocked by dirt deposits , so that the flocculant spray part 5 cannot work normally; at the same time, the discharge of flocculation mixed water and the free mixing of sewage, the mixing efficiency of suspended impurities in sewage and flocculation mixed water is not high, slowing down the speed of flocculation and sedimentation, while the flocculation of sedimentation Impurities have been statically accumulated at the bottom of the tank for a long time and condensed into agglomerates, which is not conducive to the discharge of flocculated and precipitated impurities; therefore, the inventor has made further improvements on the basis of Example 1, and the improvement scheme is as follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com