Lofting and unfolding method for steel outfitting pipe

A technology of iron outfitting and unfolding diagram, which is applied to ships and other directions, can solve the problem of insufficient deployment accuracy of iron outfitting tubes, and achieve the effect of improving the lofting deployment accuracy and ensuring the connection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

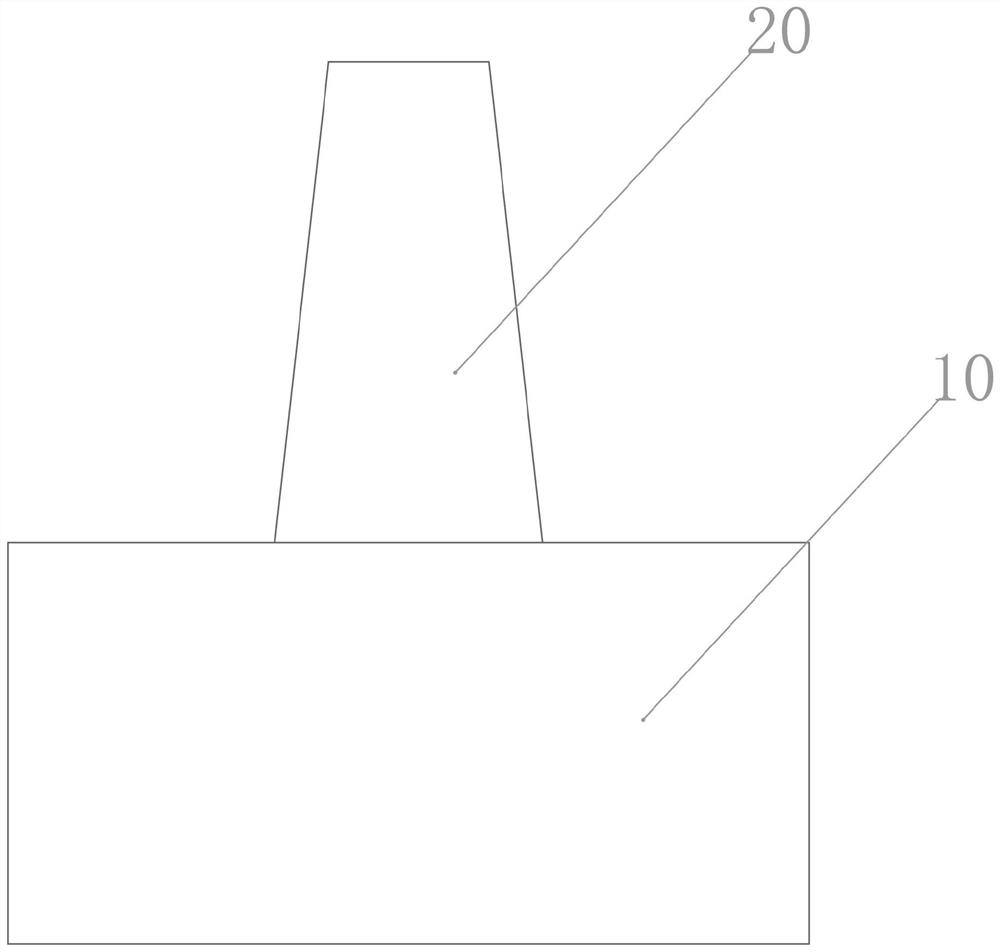

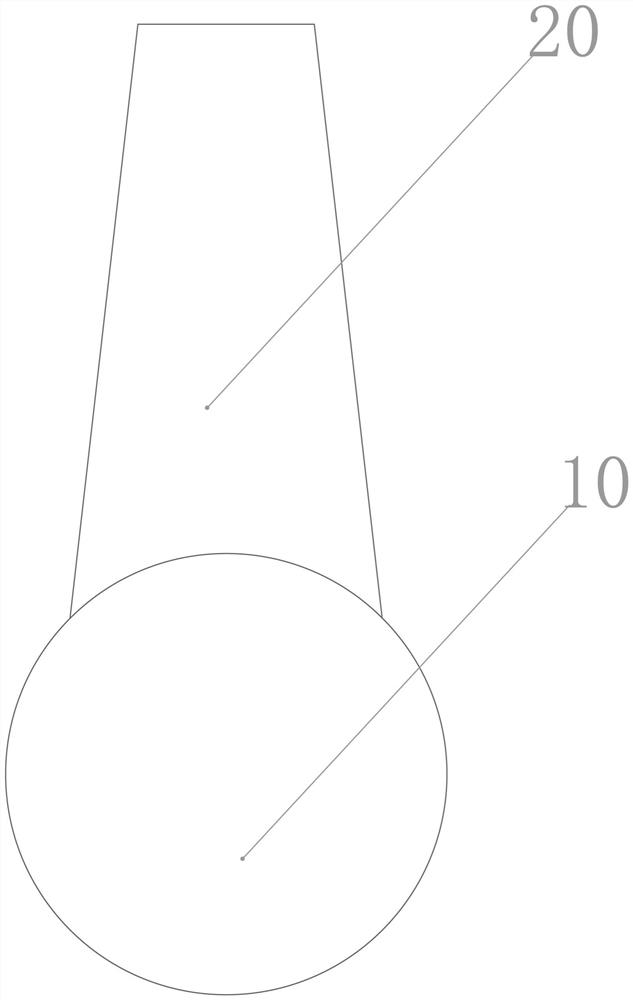

[0057] Specific embodiments, this embodiment will be described in detail by taking N=12 and the center point o' of the upper end surface of the tapered pipe 20 as a reference point example. Such as Figure 1-Figure 9 As shown, a method for lofting and expanding an iron outfitting pipe, the iron outfitting pipe includes a cylindrical pipe 10 and a tapered pipe 20 connected in series, the method includes:

[0058] S1: if figure 1 , figure 2 As shown, according to the technical requirements for the design and manufacture of iron outfitting pipes for marine accessories, the front view and side view of the outer contour of the cylindrical pipe 10 and the conical pipe 20 are obtained.

[0059] S21: if Figure 4 As shown, in the front view, first take the center point o' of the upper end surface of the tapered pipe 20 (the upper end surface of the tapered pipe 20 refers to the upper nozzle of the tapered pipe 20) as the center of the circle, and the upper end surface of the taper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com