A pulse type high flow injection device

A spray device and high-flow technology, which is applied in the field of water jet, can solve the problems of difficult adjustment, bulkiness, and unadjustable spray water pressure, and achieve the effect of increasing the impact force and increasing the pressure adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

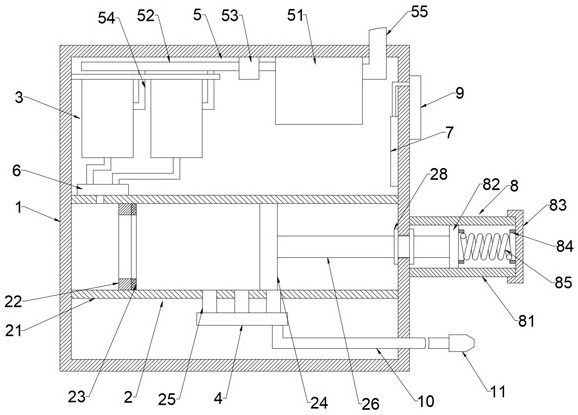

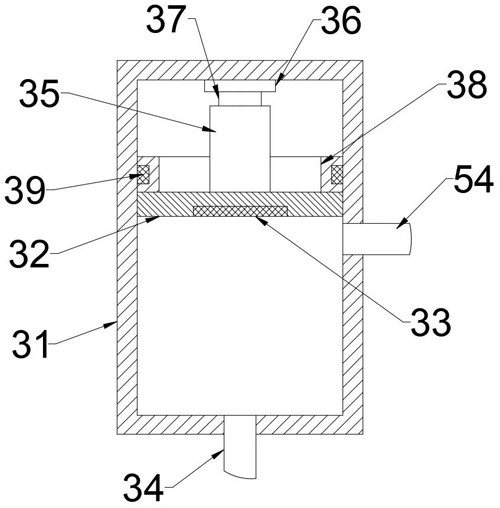

[0028] like figure 1 As shown in a pulsed high flow injection apparatus includes a housing 1, the injection assembly 2, assembly 5 and the pressure regulator supply assembly 8, is attached to the housing 1 and the water injection assembly 2 component 5, assembly 5 with water means for providing a steady stream of input, the water supply assembly 3 is connected with a dosing assembly 5 between the injection assembly 2, 3 is used to add a liquid component injection assembly 2 makeup flow pulse jet injection assembly 2, the injector assembly can 2 to obtain higher injection pulse injection flow rate may be greater impact upon injection, side pressure adjusting assembly 8 is mounted on the housing 1, the pressure regulator assembly 8 is connected to the injection assembly 2, assembly 2 may be injection providing a resilient pressure tight, water continuously charged in the injector assembly 2 at the same time, the elastic force of the pressure regulating assembly 8 is gradually increa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com