Grinding device for suspension production and grinding method thereof

A suspension and grinding technology, applied in chemical instruments and methods, solid separation, sieves, etc., can solve problems such as insufficient grinding and affect the quality of the suspension, and achieve good grinding efficiency and effect. Good, high-quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

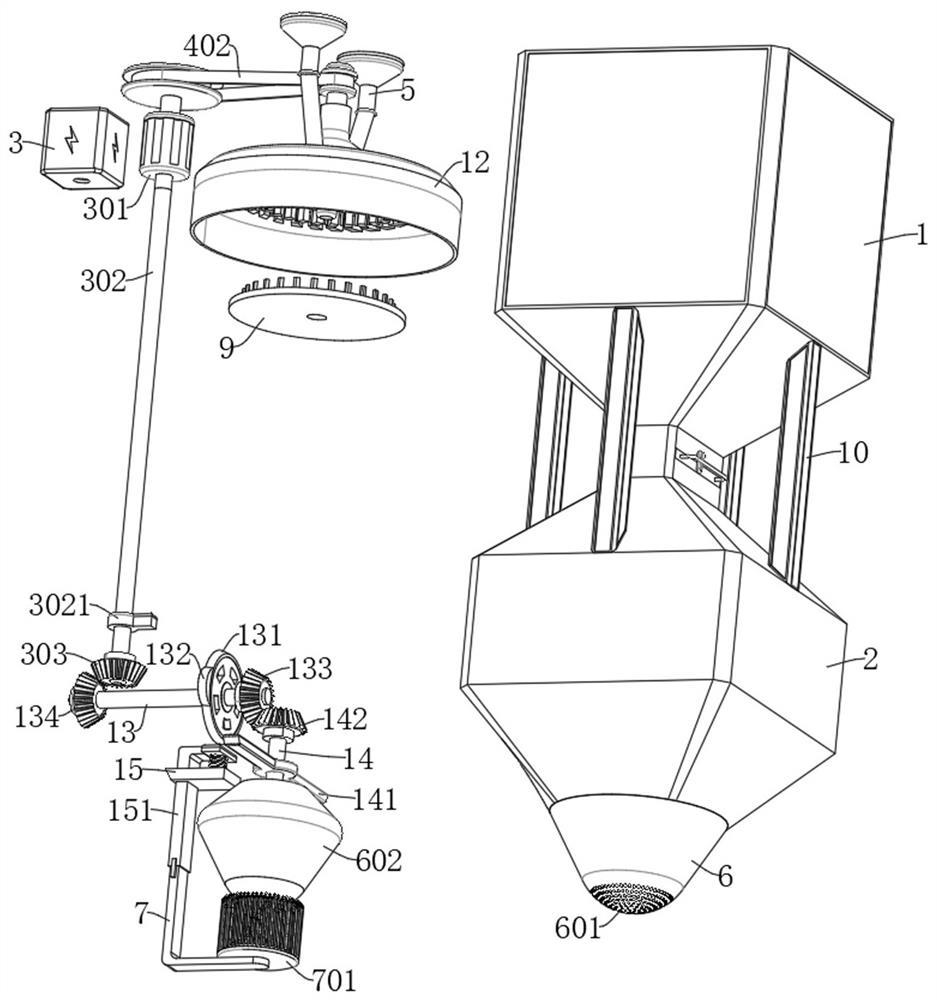

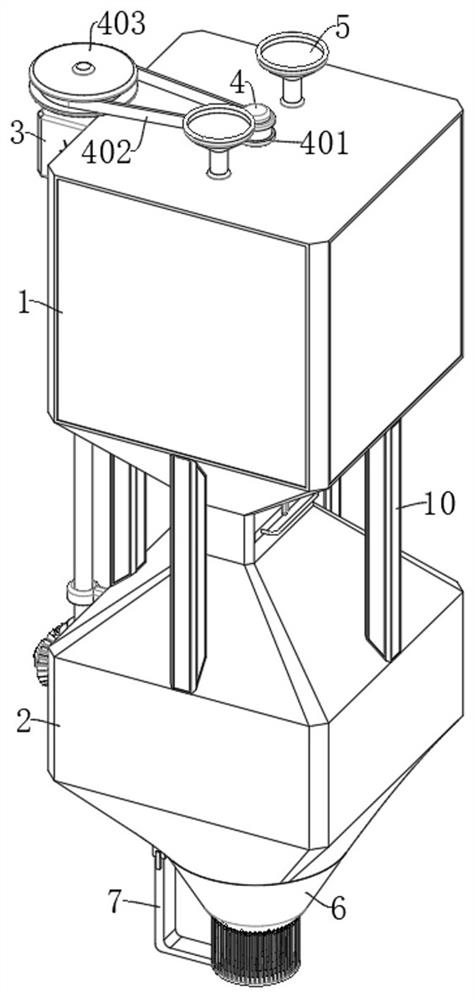

[0051] see Figure 1-Figure 9 , the present invention provides the following technical solutions:

[0052] A milling device for suspension production, comprising:

[0053] The crushing box 1 has a discharge opening at the bottom;

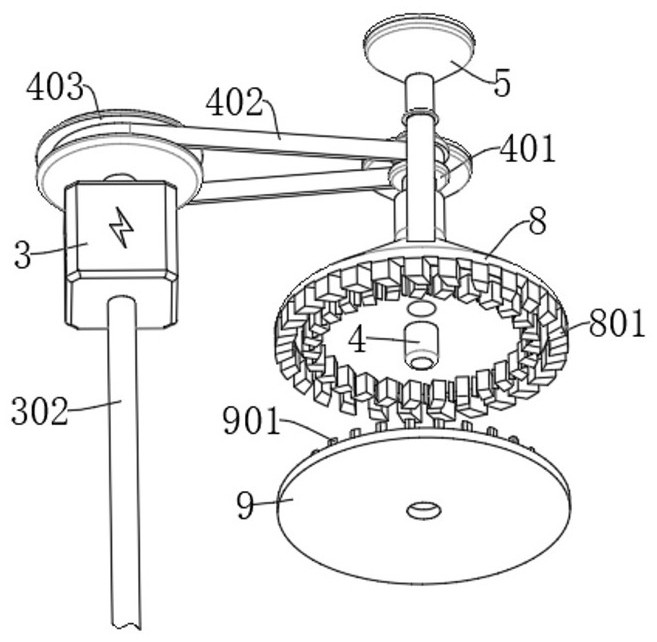

[0054] A solid crushing cover 8, the solid crushing cover 8 is fixed on the top wall of the crushing box 1, and the bottom of the solid crushing cover 8 is fixed with a plurality of evenly distributed inner crushing blocks 801 and outer crushing blocks 802, and a plurality of outer crushing blocks 802 are fixed. The broken pieces 802 are all located inside the plurality of inner broken pieces 801;

[0055] A feed hopper 5, the feed hopper 5 is fixed on the top of the crushing box 1, and the bottom of the feed hopper 5 extends downward and penetrates the bottom of the solid crushing cover 8;

[0056] The second rotating rod 4, the second rotating rod 4 is rotatably connected to the top of the crushing box 1, and the lower end of the second rotatin...

Embodiment 2

[0078] This embodiment 2 provides a grinding method of a grinding device for suspension production, which is used to further illustrate the working process or principle of the suspension production grinding device provided in the above-mentioned embodiment 1 , which are as follows:

[0079] A milling method of a milling device for suspension production, comprising the steps of:

[0080] S1, feeding: first, add the Chinese medicine granules for preparing the suspension from the feed hopper 5 to make it flow to the top surface of the chassis 9;

[0081] S2. Centrifugal crushing: start the biaxial motor 301 at this time, and its upper output shaft drives the large pulley 403 to rotate, and the large pulley 403 drives the small pulley 401 to rotate through the belt 402. Because the diameter of the large pulley 403 and the small pulley 401 different, so that the small pulley 401 is in a high-speed rotation state. At this time, the small pulley 401 drives the chassis 9 to rotate at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com