Automobile oil head pipe testing fixture and use method thereof

A technology of inspection tool and oil head, applied in the direction of using mechanical devices, measuring devices, instruments, etc., can solve the problems of less structure, the detection accuracy needs to be improved, and parts cannot be protected, so as to improve the efficiency, improve the anti-skid effect and stability, The effect of improving the inspection pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

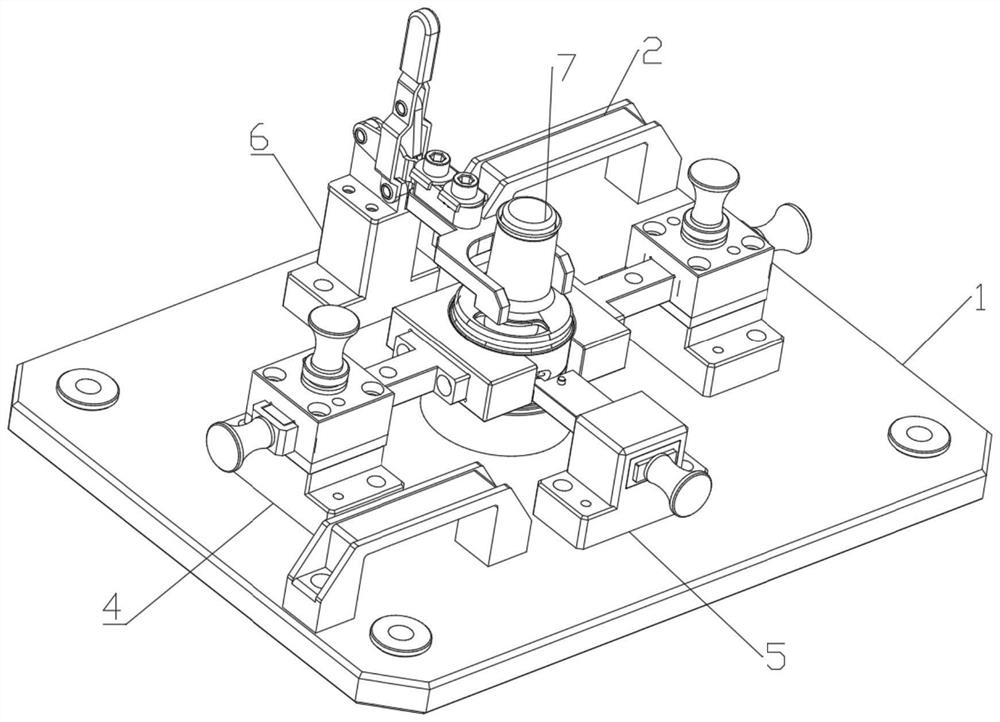

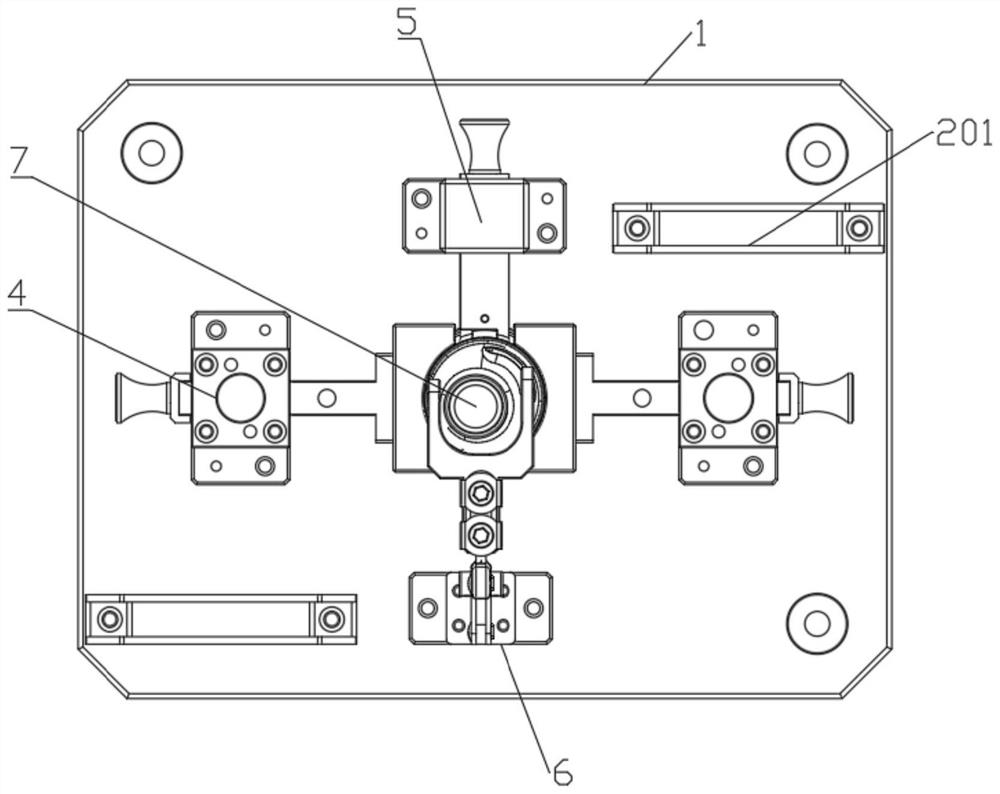

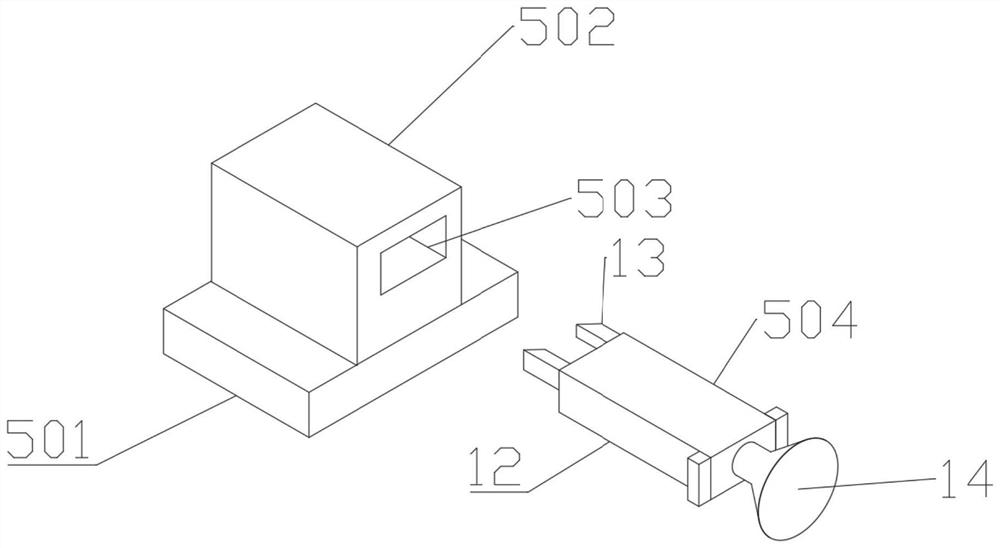

[0043] Such as Figure 1-Figure 7 As shown, the automotive oil head pipe inspection tool provided in this embodiment and its use method include a base 1, a moving mechanism 2 is fixedly arranged on the upper surface of the equipment base 1, a rubber anti-skid pad 18 is fixedly arranged under the base 1, and the moving mechanism 2 Including handles 201, two handles 201 are fixedly arranged on the upper end surface of the base 1, and the two handles 201 are respectively arranged at the opposite corners of the upper end surface of the base 1, and the surface of the handles 201 is provided with anti-slip lines, and the handles 201 are convenient for inspection equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com