Marine low-vibration low-noise vertical self-priming centrifugal pump

A low-vibration and low-noise technology, applied in the field of centrifugal pumps, can solve the problems of increasing the operating load of the device, increasing the load of the rotating shaft and bearing of the device, and shaking the device, and achieves the effect of slowing down the damage speed, prolonging the service life and improving the filtering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

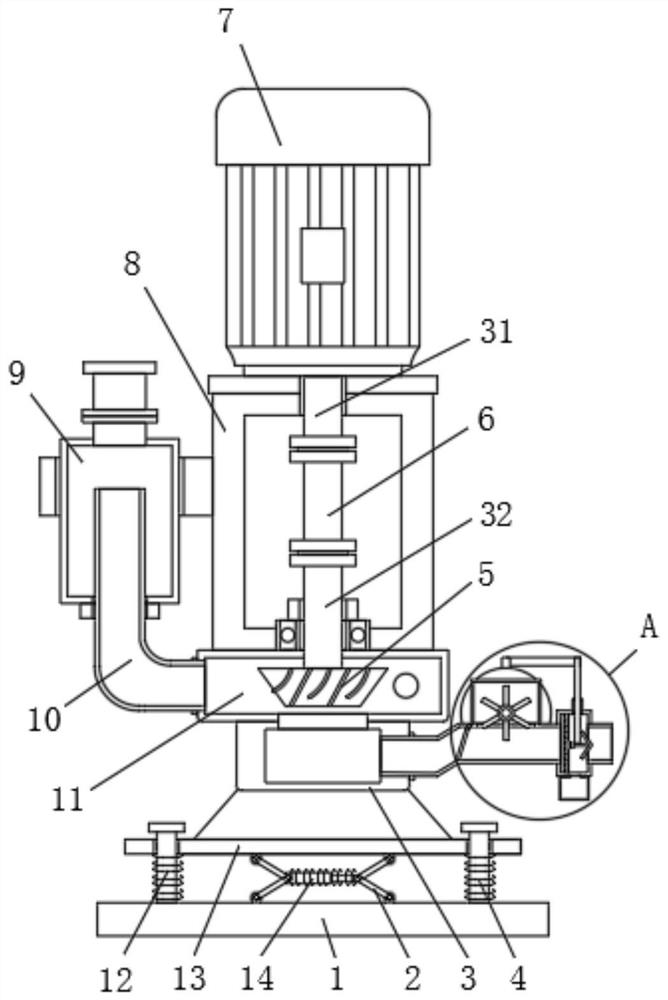

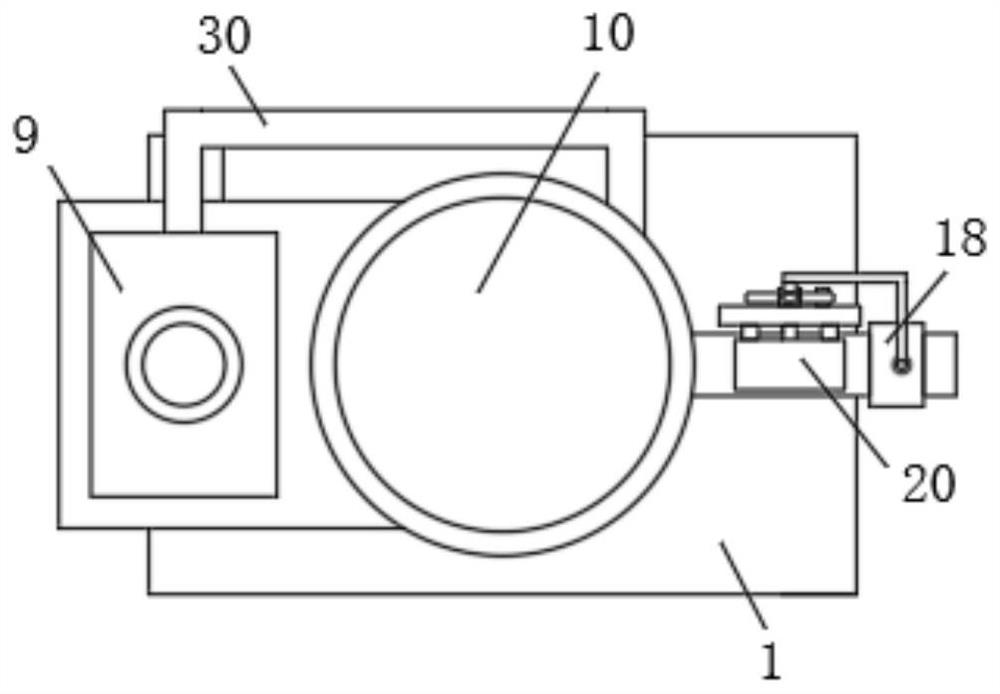

[0038] Example 1, such as Figure 4-6 As shown, when the device pumps water, when the water flow enters the filter chamber 18, the impurities in the water flow can be filtered through the filter screen plate 33, so as to reduce the load caused by the impurities on the water pump, and when the filtered water flow flows into the water inlet pipe 17, it will The dial 19 impacts, and the continuous impact of the water flow can drive the dial 19 to rotate, and then the rotating rod 25 is rotated. When the rotating rod 25 rotates, it can drive the driving rod 28 to rotate along the inside of the limit groove, so that the driving rod 28 can push the movable groove 26 under the sliding limit of the sliding rod 27 by the limit plate 21 to make the sliding rod 27 slide up and down repeatedly, and the sliding rod 27 can drive the movable rod 23 to slide up and down through the L-shaped rod 22, when the movable rod When 23 slides up and down, it can drive the brush plate 24 to move up and...

Embodiment 2

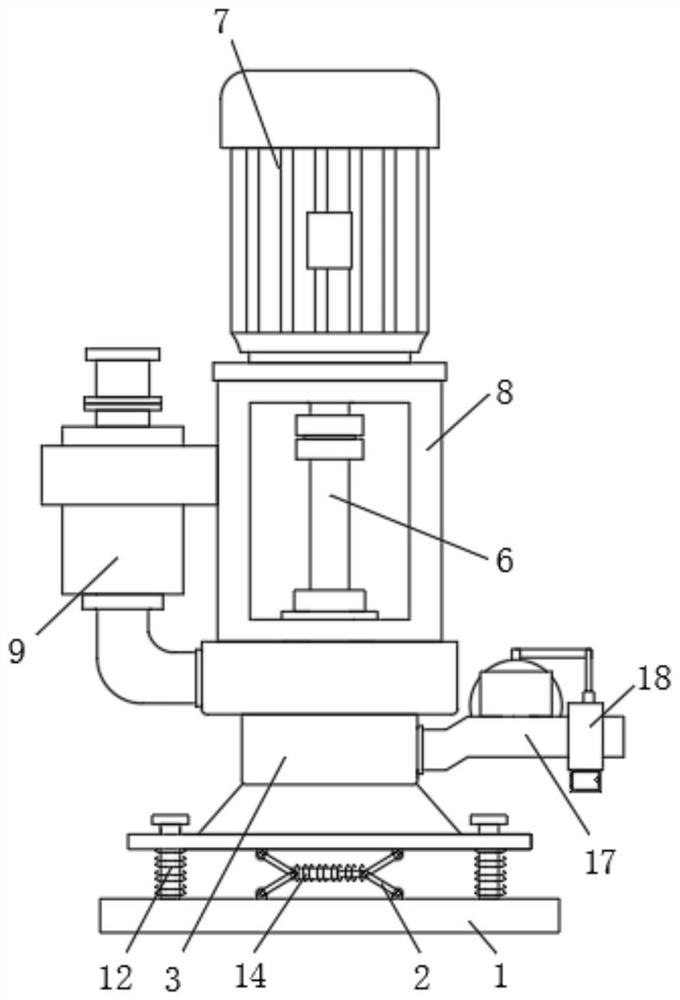

[0039] Example 2, such as Figure 5 As shown, when the device is shaken, it will cause the connecting plate 13 to vibrate, and the extrusion caused by the connecting plate 13 to the inner sleeve A12 can relieve the shaking of the device, and the connecting plate 13 can be connected to the hinge rod 2 Features, push the outer sleeve A14 and the inner sleeve B15 close to each other, squeeze the spring B16, the rebound force of the spring B16 can form a conflict, and relieve the shaking of the device again. When the hull is tilted, it can effectively reduce the impact of the shaking on the device The impact caused by the swing force reduces the load on the bearing.

[0040] Working principle: When the device is used for the first time, add water into the gas-liquid separator 9, and after the liquid enters the gas-liquid separator 9, it can be diverted to the pump water tank 11 through the circulation pipe 30, and when the required amount of water is injected, start The motor 7 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com