An automatic sewing machine based on anti-broken thread for cloth textiles

A textile and anti-broken thread technology, which is applied in the field of sewing machines, can solve problems such as the inability to automatically warn the anti-broken thread structure, the lack of adjustment of the position of the thread roller, and the inability to replace the wire mechanism, etc., so as to reduce replacement, have a good cushioning effect, and avoid being pulled broken effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

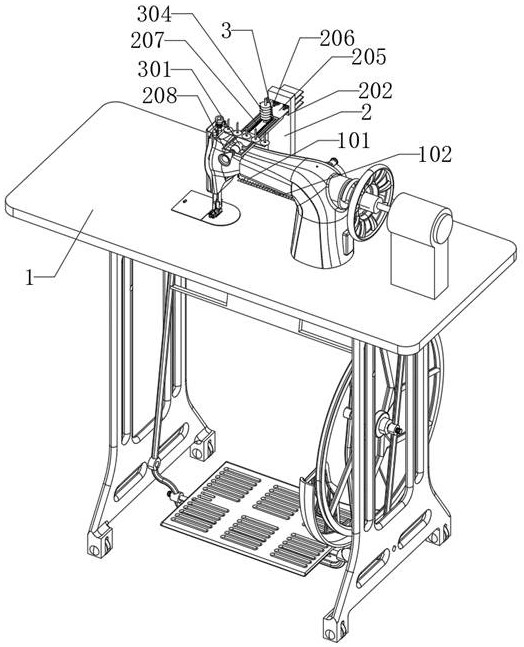

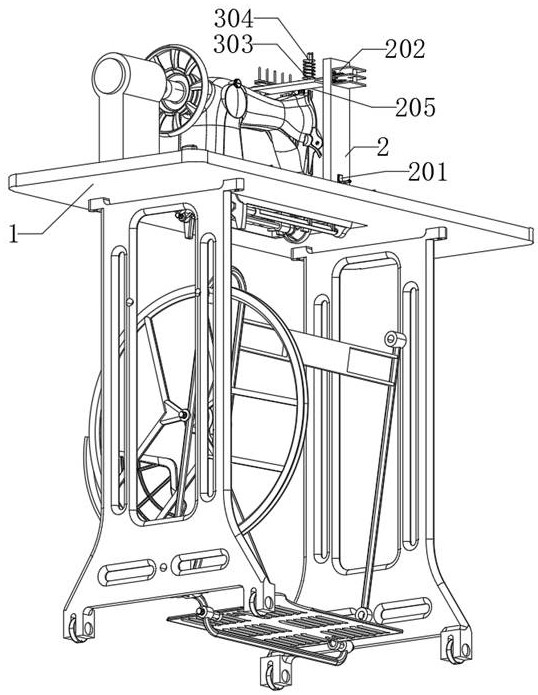

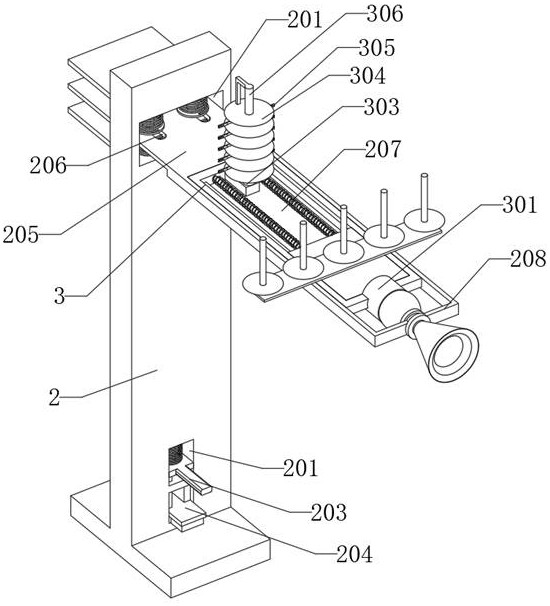

[0031] as attached figure 1 To attach Figure 8 Shown:

[0032] The present invention provides an automatic sewing machine based on anti-broken thread for cloth and textiles, which includes a main body 1; the main body 1 is the body of the automatic sewing machine, and a motor is connected to the top side of the main body 1, and an adjustment member 2 is installed on the top side of the main body 1 Adjustment part 2, the adjustment part 2 includes an auxiliary buffer mechanism, the top of the adjustment part 2 is equipped with an auxiliary buffer mechanism, the adjustment part 2 is a T-shaped plate structure, and the bottom of the adjustment part 2 is embedded in the inside of the chute 101, the adjustment The top plate 205 at the top of the part 2 is equipped with a moving part 3, and the adjusting part 2 plays the role of adjusting the position; 3 is installed inside the auxiliary groove 207. The inside of the moving part 3 is provided with a rectangular block. The moving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com