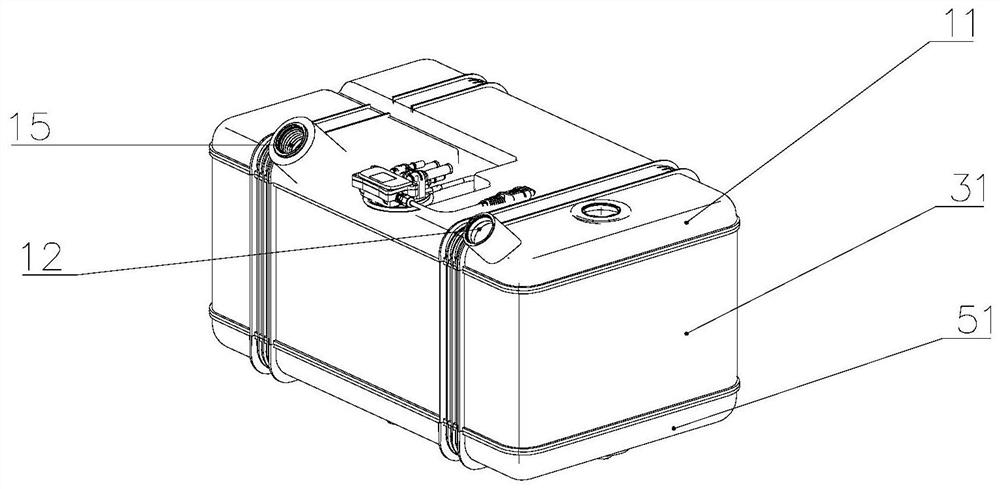

A grid-shaped fuel tank

A grid-like and grid-like technology, which is applied in the field of auto parts, can solve problems such as vehicle center of gravity deviation, stress concentration of clapboard and box welds, and influence on driving safety, so as to prevent deformation or cracking and fuel impact. The effect of uniformity and reduction of surge phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

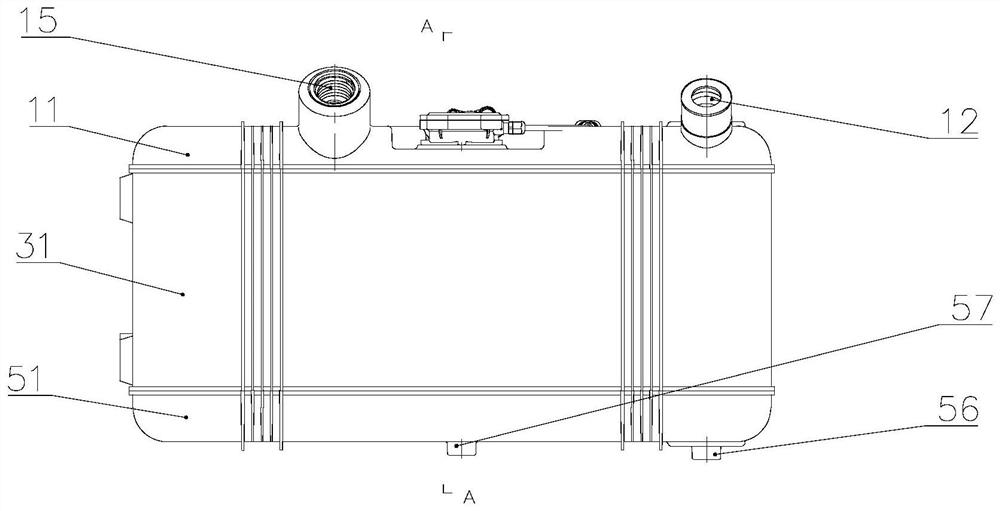

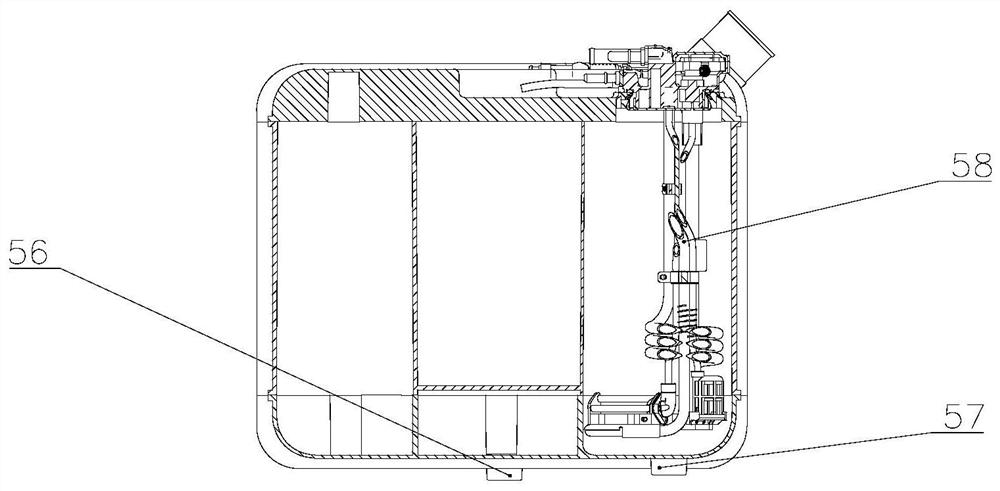

[0056] like Figure 1-10 As shown, Embodiment 1 of the present application discloses a grid-shaped fuel tank, which includes: a fuel tank housing, which surrounds a cavity including a fuel chamber, and the fuel tank housing includes an upper upper housing area, a middle The middle shell area and the lower shell area of the lower part; the middle grid rib 32 structure is set in the cavity corresponding to the height area of the middle shell 31, and the middle grid rib 32 structure divides the middle part of the cavity into several middle grid cavities. The grid cavities are not connected in the radial direction, and the bottom end of the first middle grid cavity group included in the middle grid cavity is provided with an oil opening to communicate with each other to form a fuel cavity. The middle part of the cavity is divided into several middle grid cavities by setting the middle grid rib 32 structure, and the middle grid cavities are not connected in the radial direction...

Embodiment approach

[0075] As an implementation manner, the lower housing area includes side walls and a bottom wall, and the oil flow port 53 extends upward from the connection between the lower grid ribs 52 and the bottom wall. This arrangement can ensure the smooth flow of fuel from the oil flow port 53 .

[0076] Specifically, the structure of the lower grid rib 52 is composed of several lower partitions arranged and connected to form a grid shape. One end of the first lower grid cavity 54 is opened to communicate with the first middle grid cavity 33, and the other end is connected to the lower shell area. connected to the bottom wall.

[0077] Specifically, the lower casing 51 below one of the first middle grid chambers 33 is provided with a boss, and the boss is installed with a fuel drain bolt 56 as a fuel drain port.

[0078] Specifically, the upper casing 11 above one of the first middle grid chambers 33 is provided with a boss, and the boss is used for installing a fuel sensor.

[007...

Embodiment 2

[0092] Such as Figure 1-10 As shown, Embodiment 2 of the present application provides an integrated fuel tank, which includes the grid-shaped fuel tank in Embodiment 1, and the middle grid chamber also includes a second middle grid chamber group, and the first middle grid chamber group The second medium grid cavity group is not connected to each other, and the medium grid cavities in the second medium grid cavity group are connected to each other to form a urea cavity. By setting the second middle mesh chamber group, and the second middle mesh chamber group is not connected with the first middle mesh chamber group, the integrated setting of the fuel chamber and the urea chamber is realized, which reduces the volume of the integrated fuel tank and saves energy. The combined weight of the two makes the vehicle lighter; in addition, by integrating the fuel chamber and the urea chamber, the heat of the fuel chamber can heat the urea chamber, realize the reuse of heat, and avoid t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com