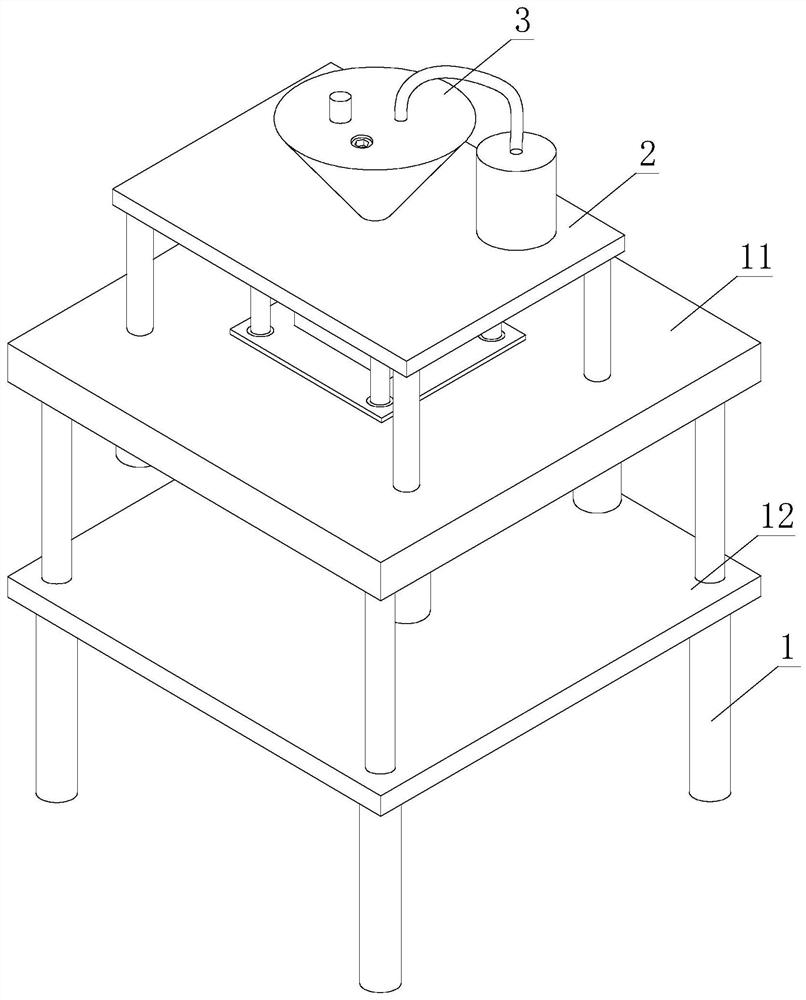

High-pressure heating casting device for pig iron production and implementation method of high-pressure heating casting device

A high-pressure, pig-iron technology, applied in foundry equipment, foundry molding equipment, molds, etc., can solve the problems of inability to replace the foundry sand, imperfect product performance, and poor quality of finished products, and to improve the convenience of adjustment, The effect of convenient pressing and smooth dredging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

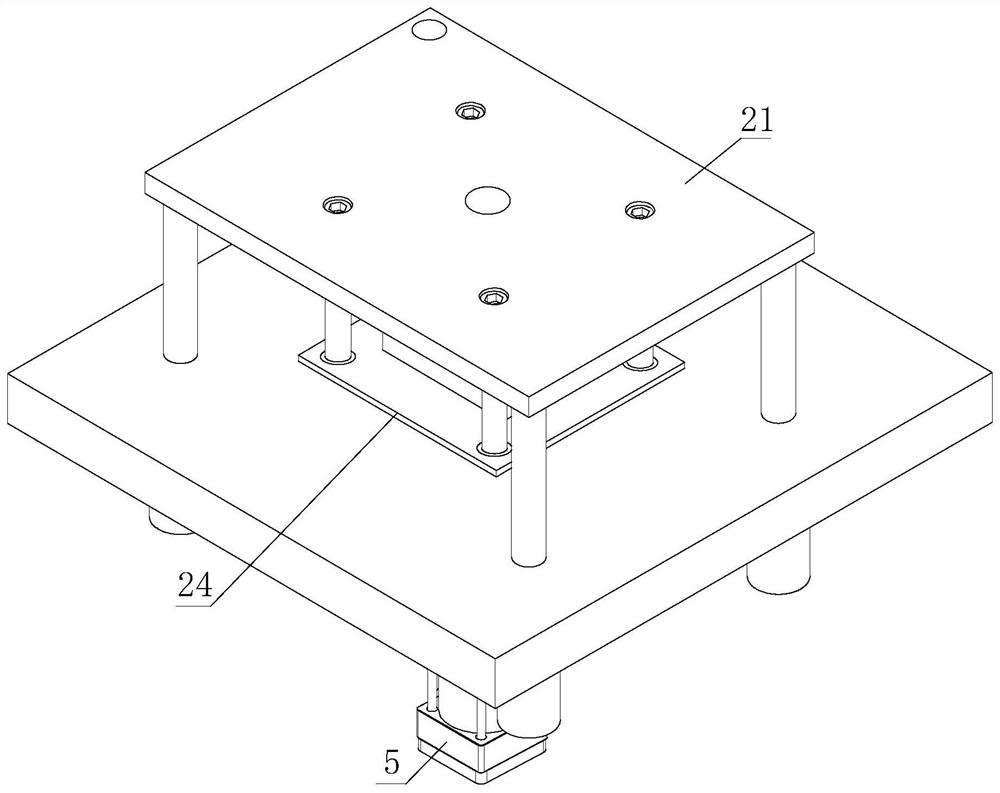

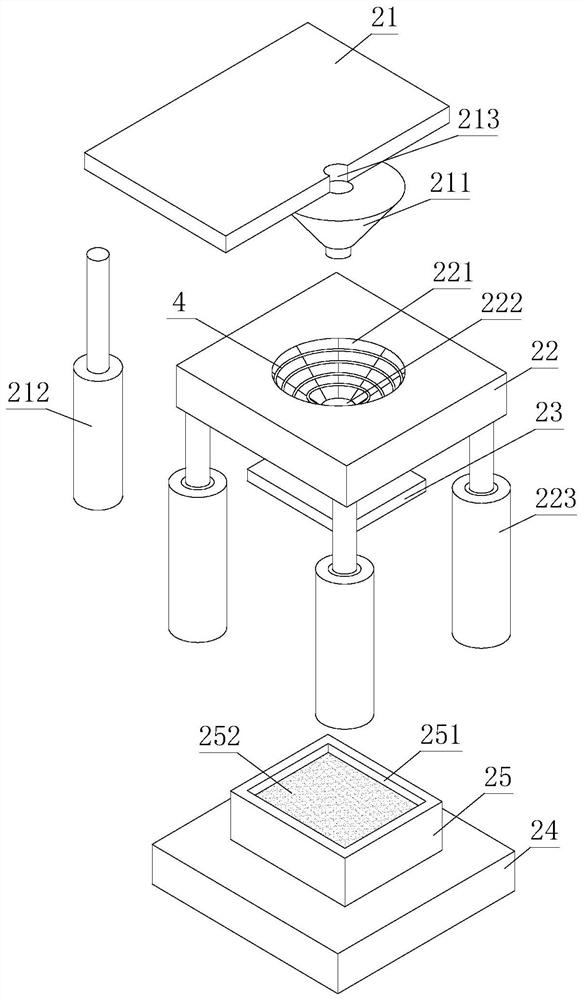

[0039] In order to better demonstrate the process of a high-pressure heating casting device for pig iron production, this embodiment proposes a method for implementing a high-pressure heating casting device for pig iron production, including the following steps:

[0040] Step 1: Place the shaping sand 252 in the molding groove 251, press down the adjustment cylinder 223 to drive the upper die seat 22 and the upper mold 23 to press down, compact the shaping sand 252 in the shaping groove 251, and then place the object to be cast Place it in the shaping sand 252, press down the adjustment cylinder 223 to drive the object down, and press the groove for molding in the shaping sand 252;

[0041] Step 2: After the mold is pressed, press down the adjustment cylinder 223 and the pressing cylinder 212 together to press the upper connecting plate 21, the upper die base 22 and the upper die 23 on the lower die base 24, and the feeding pipe 34 conveys the casting material liquid, and duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com