Gas network and method for detecting leaks in a gas network under pressure or under vacuum

A gas and network technology, applied in fluid pressure actuation devices, fluid pressure actuation system safety, gas/liquid distribution and storage, etc., can solve problems such as pipeline network leakage is not allowed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

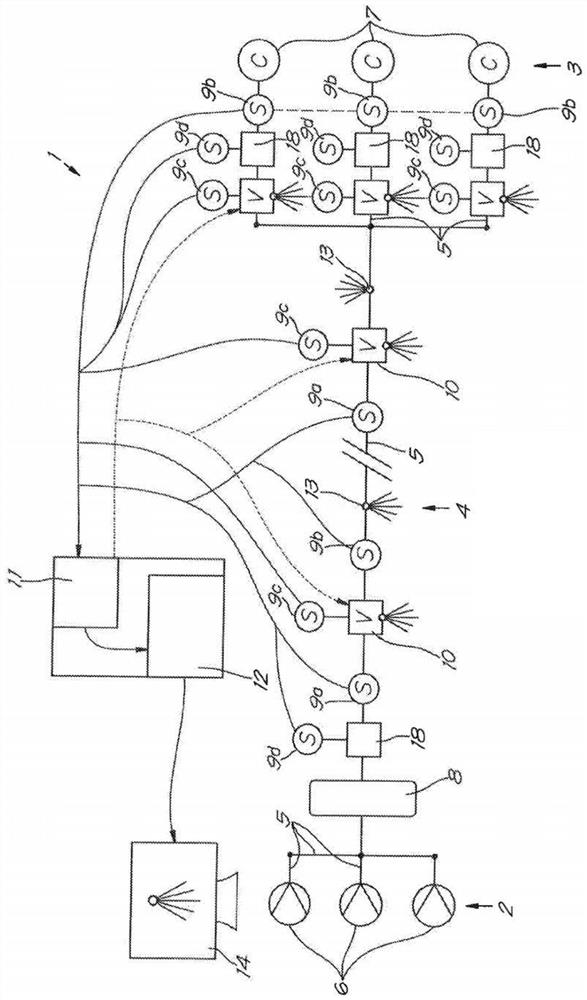

[0059] figure 1 The gas network 1 in mainly comprises a source side 2, a consumer side 3 and a network 4 of pipes 5 in between.

[0060] In this case, the gas network 1 is a gas network 1 under pressure. The gas may be air, oxygen or nitrogen or any other non-toxic and / or harmful gas or gas mixture.

[0061] The source side 2 comprises a number of compressors 6, in this case three, which generate compressed air. The consumer side 3 includes a plurality of compressed air consumers 7 , in this case also three.

[0062] It is also possible that the compressor 6 contains a compressed air dryer.

[0063] It is not excluded that there may also be a compressor 6 downstream of the gas network 1 . This is called a "booster compressor".

[0064] Compressed air is conveyed from the compressor 6 to the consumer 7 via a network 4 of pipes 5 . This network 4 is in most cases a very complex network of pipes 5 .

[0065] figure 1 This network 4 is shown in a very schematic and simplifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com