Lifting type elevator shaft operation platform using triangular supporting frame and screw opposite-pulling system

A triangular support and operating platform technology, which is applied to the accessories of scaffolding, scaffolding supported by house structure, and house structure support, etc., can solve the problems of small adaptability, large material investment, and high risk factor, and achieve small adaptability and material input. Large, high-risk effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

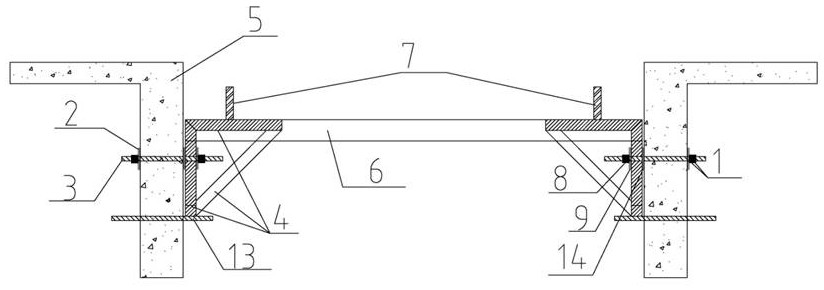

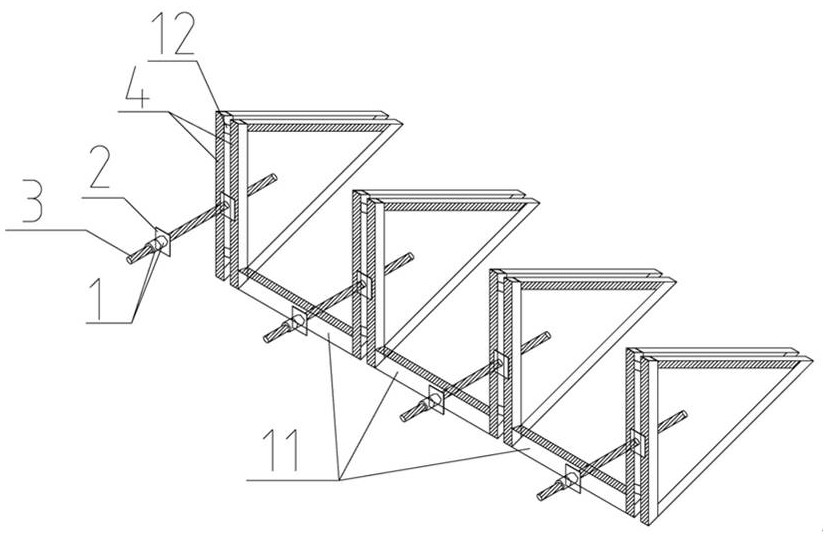

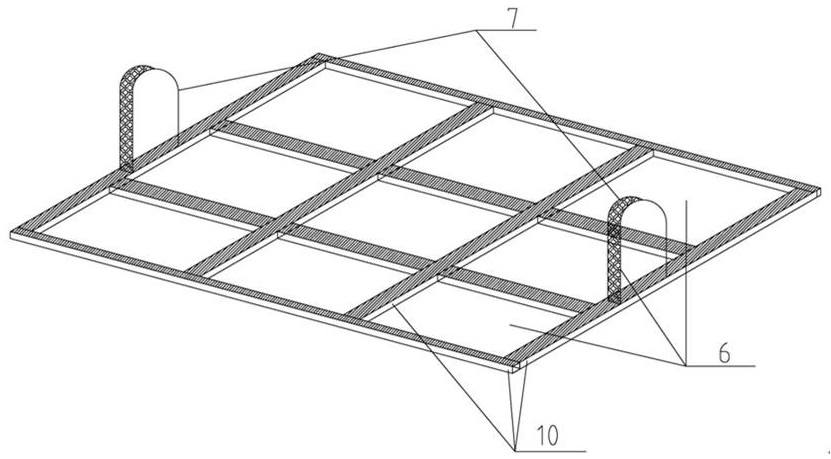

[0023] Additional aspects and advantages of embodiments of the invention will be set forth in the description which follows, and in part will be obvious from the description, or may be learned by practice of embodiments of the invention. combine Figure 1-Figure 3 , the embodiment of the present invention provides a lifting elevator shaft operating platform using a triangular support frame and a screw pull system, including: a platform 10, the platform 10 is a grid frame member formed by welding a plurality of square steels, and the platform 10 Patterned steel plates 6 are laid on the surface layer and its surroundings. The lower surface of the platform 10 is provided with a plurality of triangular support frames 4. The plurality of triangular support frames 4 are evenly arranged on both sides of the platform 10. The plurality of triangular support frames 4 pass through the wall respectively. The bolts 3 are fixedly connected to the concrete wall 5 inside the elevator shaft, a...

Embodiment 2

[0028] The embodiment of the present invention provides a method of using the hoisting elevator shaft operating platform using the triangular support frame and the screw pull system, specifically as follows:

[0029]The surface layer of the aluminum alloy platform 10 of the embodiment of the present invention is laid with a 3mm thick patterned steel plate 6, and the bottom keel is an integral structure welded by aluminum alloy square tubes of 40mm×70mm×1.5mm. Φ20mm round steel hoisting pull rings 7 are welded on the top, which are used for the fixed point of the tower crane hoisting wire rope. The bottom of the aluminum alloy platform 10 is supported by an aluminum alloy triangular support frame. The 100mm×5mm square steel gasket is welded, and is connected and fixed to the inner concrete wall of the elevator shaft through the 600mm long M12 wall-through bolt. During construction, the tower crane can be used to fix the hoisting steel wires on the two hoisting pull rings 7, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com