Double-layer high-pressure rotary spraying anti-seepage wall with vertical plastic laying device and its construction method

A technology of high-pressure rotary spraying and vertical plastic laying, which is used in construction, earthmoving machines/shovels, etc., can solve the problems of reducing the grooving efficiency of grooves of different widths, and achieves the improvement of grooving efficiency, width range, and improvement. The effect of the slotting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

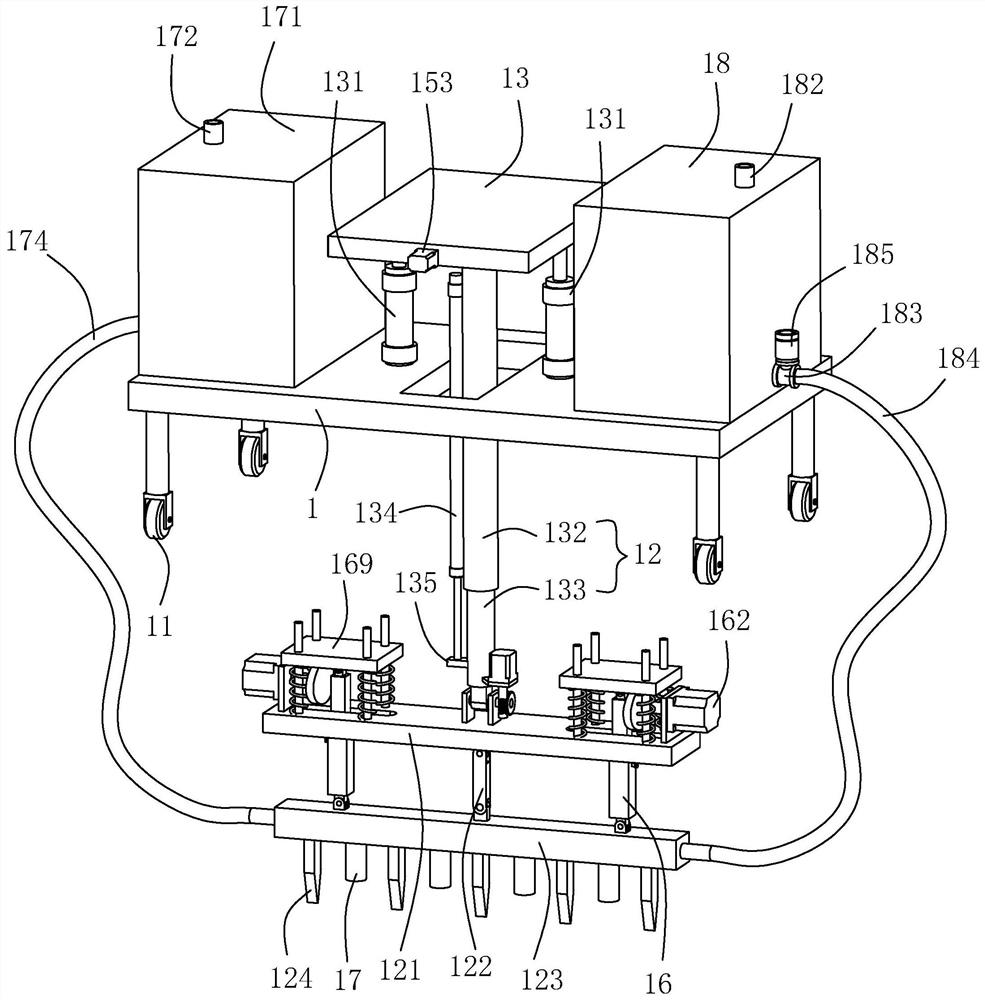

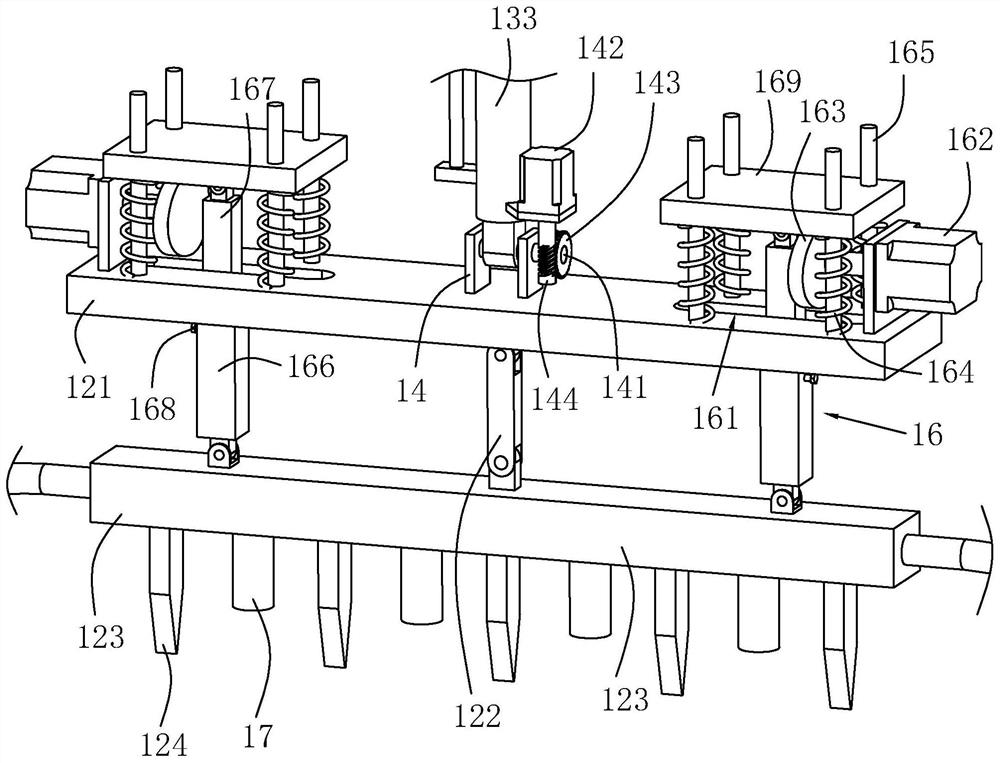

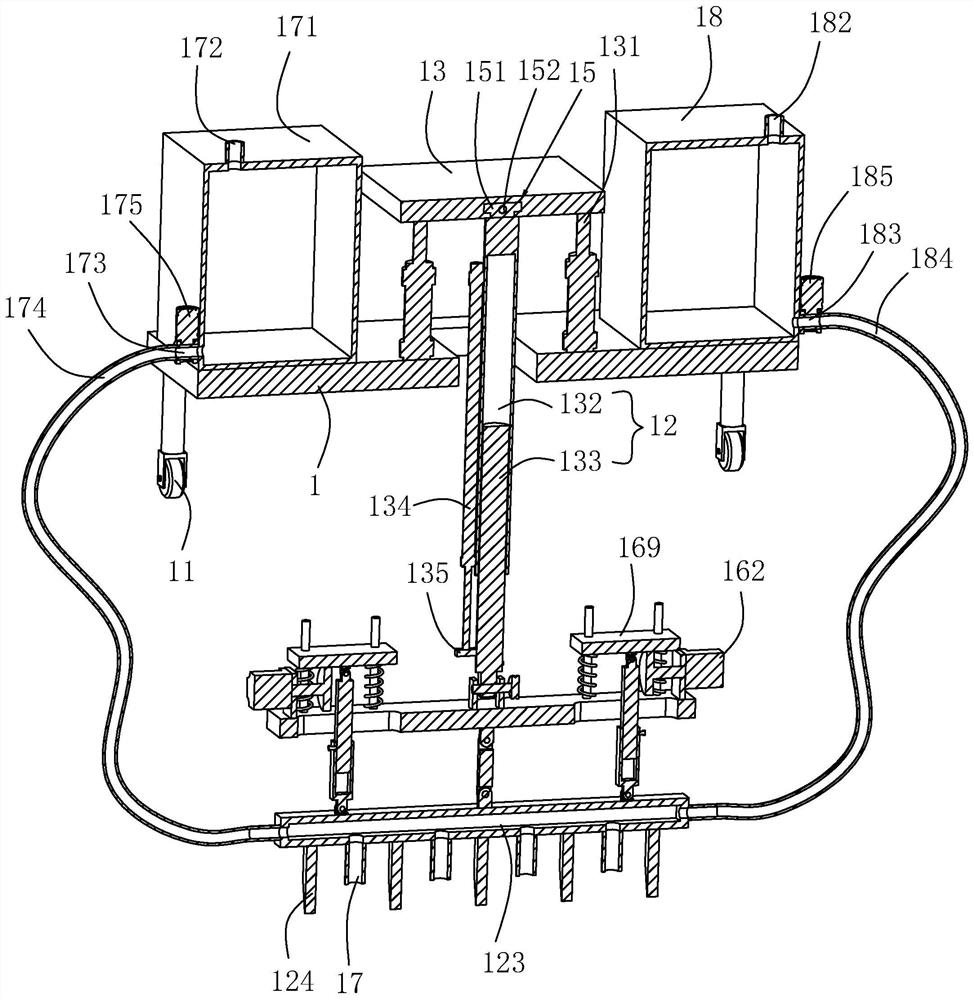

[0040] Attached to the following Figure 1-3 This application will be described in further detail.

[0041] The embodiment of the present application discloses a double-layer high-pressure rotary-spraying anti-seepage wall with an inner clip and a vertical plastic-spreading device. refer to figure 1 , a double-layer high-pressure rotary-spraying anti-seepage wall with a vertical plastic-spreading device, comprising a moving plate 1, rollers 11 are arranged under the moving plate 1 and located at the four corners of the moving plate 1, and a rod body 12 is penetrated on the moving plate 1, and the rod body 12. A mounting rod 121 is provided at the end of the lower part of the moving plate 1, and a hinge rod 122 is hinged on the surface of the mounting rod 121 away from the rod body 12. The end of the hinge rod 122 away from the mounting rod 121 is hinged with a connecting rod 123. A plurality of slotting knives 124 are evenly arranged on the surface of the 123 away from the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com