Vehicle lifting equipment for new energy battery replacement

A battery replacement and new energy technology, applied in vehicle maintenance, electric vehicles, vehicle energy storage, etc., can solve the problems of battery installation method errors, batteries not being installed correctly in the car, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

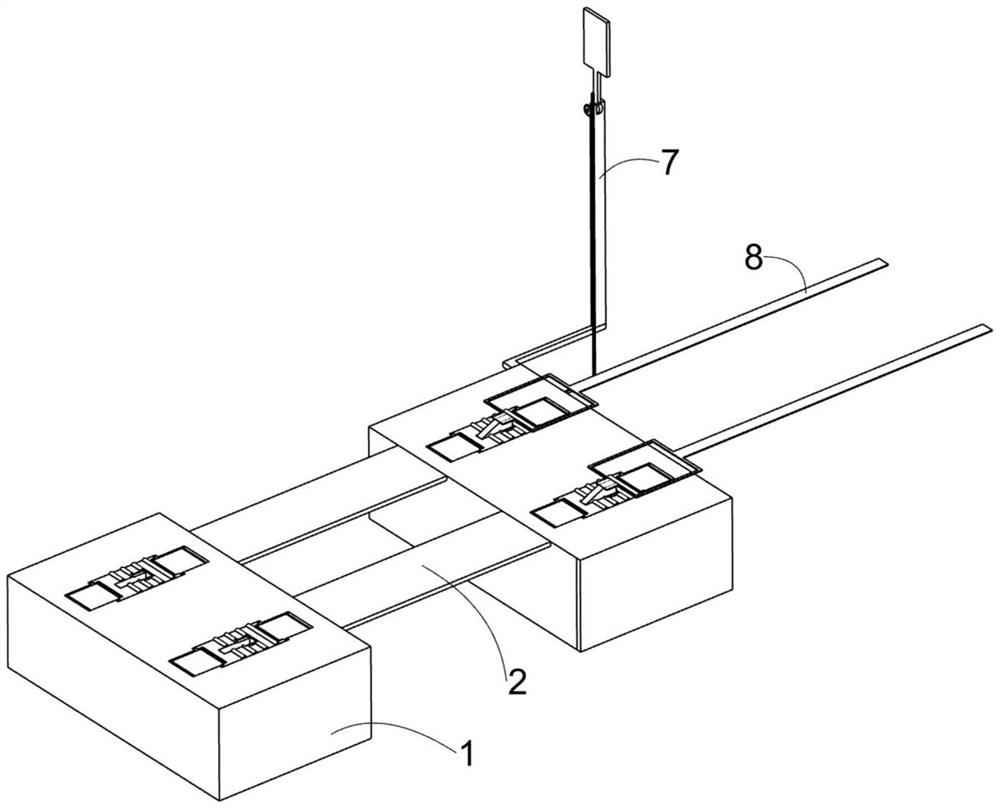

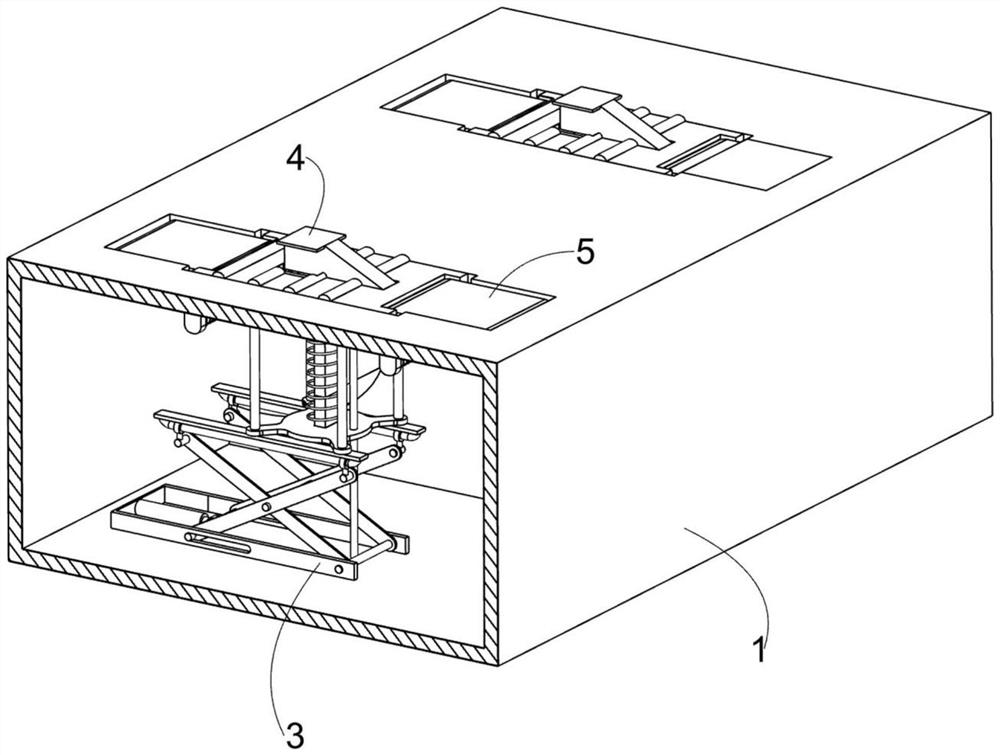

[0027] A vehicle lifting device for new energy battery replacement, such as Figure 1-8 As shown, it includes a lifting main body 1, a connecting plate 2, a lifting assembly 3, an extruding assembly 4, a limiting assembly 5, a fixed rod 6 and an extension plate 8, and a pair of connecting plates 2 are jointly supported on the two lifting main bodies 1 for The lifting assembly 3 for car lifting is symmetrically positioned in the lifting body 1, the extrusion assembly 4 is arranged on the lifting assembly 3, the extrusion assembly 4 is located in a lifting body 1, and the restriction assembly 5 for restricting the tire is of sliding type Connected to the extruding assembly 4 , the fixed rod 6 is symmetrically and fixedly connected in the lifting body 1 at the same place, and the extension plate 8 is arranged on the extruding assembly 4 .

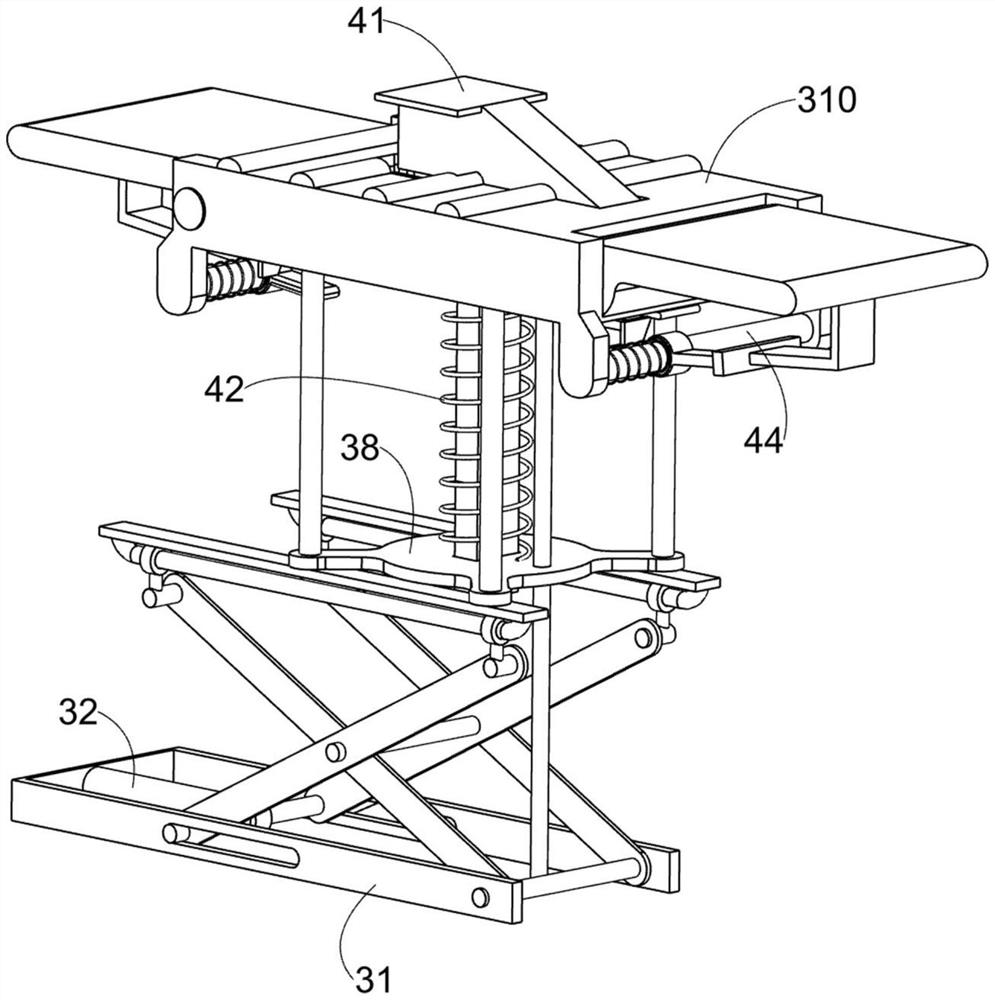

[0028] Elevating assembly 3 comprises U-shaped frame 31, hydraulic cylinder 32, moving rod 33, lifting rod one 34, lifting rod two 35, movabl...

Embodiment 2

[0035] On the basis of Example 1, such as Figure 9-10 As shown, it also includes a positioning prompt assembly 7, the positioning prompt assembly 7 is arranged on a lifting body 1, and the positioning prompt assembly 7 is used to prompt the driver. , rack 73, rotating shaft 74, gear 75 and prompt pendulum plate 76, one side of lifting main body 1 side is fixedly installed with mounting bar 71, and lower pressing bar 72 is slidably connected on lifting main body 1 at the same place, and lower pressing bar 72 One end is fixedly connected with the lower part of the extrusion block 41, a rack 73 is welded on the lower pressing bar 72, and a rotating shaft 74 is rotatably connected to the top of the mounting bar 71 away from the lifting body 1, and a gear 75 is welded on the rotating shaft 74, and the gear 75 and The racks 73 are engaged with each other, and the rotating shaft 74 is fixedly connected with a prompting pendulum plate 76. The prompting pendulum plate 76 is written wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com