Self-calibration liquid drop manipulator structure and micro-operation method

A manipulator, self-calibration technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of inability to automatically calibrate tiny objects, not widely used, complex application environments, etc., to achieve simple processing and precise control The effect of simple control method and overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

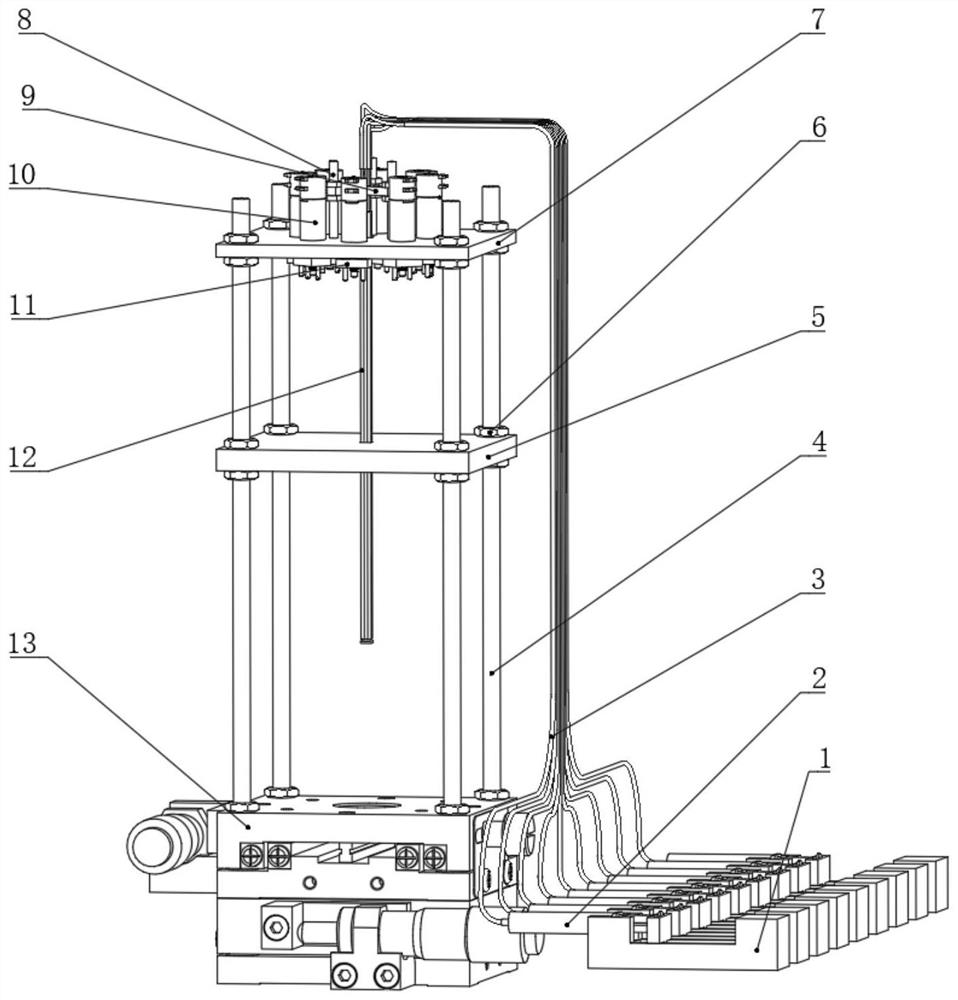

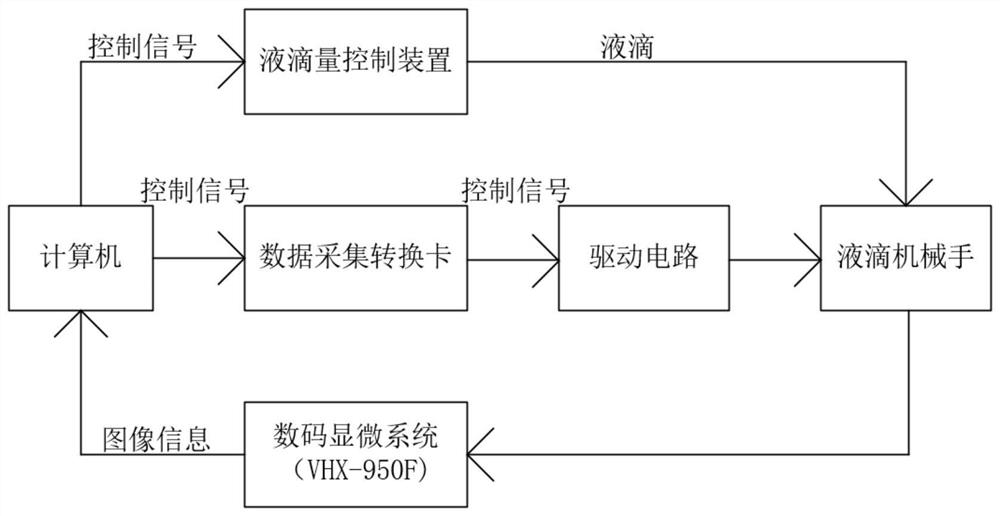

[0046] A self-calibrating droplet manipulator structure such as figure 1 , figure 2 , image 3 , Figure 4 As shown, it includes end effector assembly, droplet injection assembly, microtube drive assembly, support assembly, and control and feedback assembly;

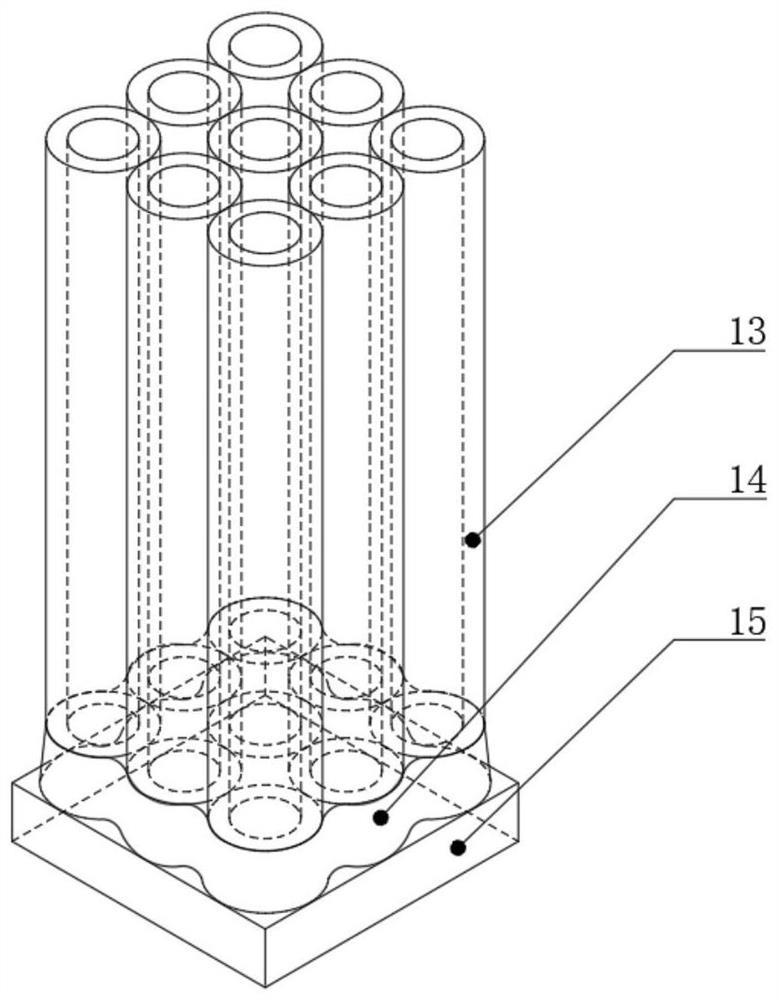

[0047] The end effector assembly includes nine capillary glass microtubes 12; the droplet injection assembly includes a syringe 2, a propeller 1 of the syringe 2, and a hose 3; The transmission connecting plate 11 nested with the drive nut 16 of the output shaft 17; each capillary glass microtube 12 is connected to the corresponding syringe 2 through the corresponding hose 3; each capillary glass microtube 12 is driven by the microtube Components move up and down;

[0048] The bracket assembly fixes and supports the end effector assembly, the droplet injection assembly, the microtube drive assembly, and the control and feedback assembly; the control and feedback assembly controls the microtube drive assembly and the...

Embodiment 2

[0072] In this embodiment, taking the adsorption of blocky rectangular objects as an example, the whole process is shown in FIG. 5 . First, control the micro stepper motor 10 to adjust the end faces of the nine capillary glass microtubes 12 to be even. Assume that the size of the rectangular object is 2.4mm×1.6mm×0.5mm, the distance between the surface center of the rectangular object and the center of the liquid droplet manipulator in the x direction is 0.3mm in the initial state, and the distance in the y direction is 0.2mm, clockwise around the center point Rotated 10 °, according to its rectangular shape, by controlling the micro stepper motor 10, the capillary glass microtubes 12 numbered g, h, i move up 2mm together, and the selected numbers are a, b, c, d, e , f capillary glass microtube 12 remains motionless. By means of the liquid drop volume control device, the capillary glass microtubes 12 respectively numbered as a, b, c, d, e, f inject equal amounts of liquid dro...

Embodiment 3

[0074]In this embodiment, taking the adsorption of a block-shaped triangular object as an example, the whole process is shown in FIG. 6 . First, control the micro stepper motor 10 to adjust the end faces of the nine capillary glass microtubes 12 to be even. Assume that the waist length of an isosceles right triangle object is 1.6mm, the height is 0.3mm, the distance between the midpoint of the hypotenuse of the triangle object in the initial state and the center of the droplet manipulator in the x direction is 0.3mm, and the distance in the y direction is 0.2mm , rotated 10° clockwise around the midpoint of the hypotenuse, according to its triangular shape, the capillary glass microtubes 12 numbered f, h, and i move up 2mm together by controlling the micro stepping motor 10, and the selected number is a , b, c, d, e, g The capillary glass microtube 12 remains still. Through the liquid drop volume control device, the equal amount of liquid droplets are injected into the capill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com