A small-diameter branch pipe welding positioning tool and positioning method

A branch pipe welding and positioning tooling technology, which is applied in the direction of welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems affecting the overall installation of ship pipeline equipment, poor position accuracy of branch pipes, and high labor intensity, so as to reduce the labor intensity of assembly , Eliminate welding deformation and improve assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

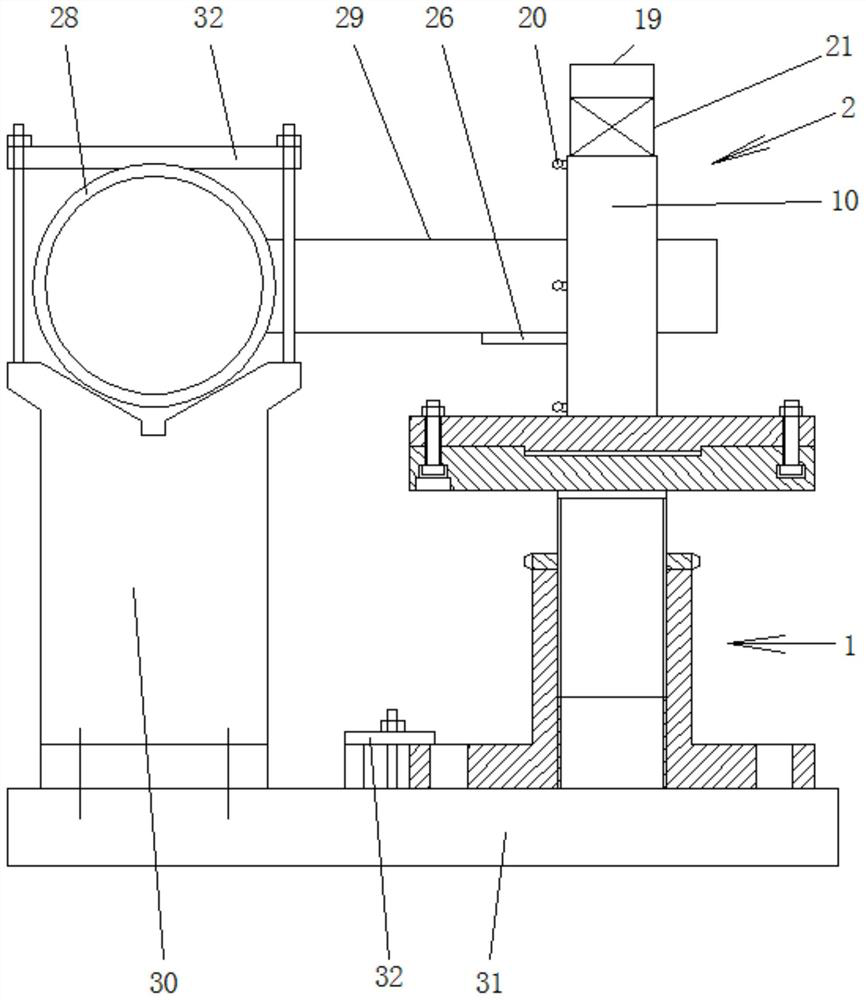

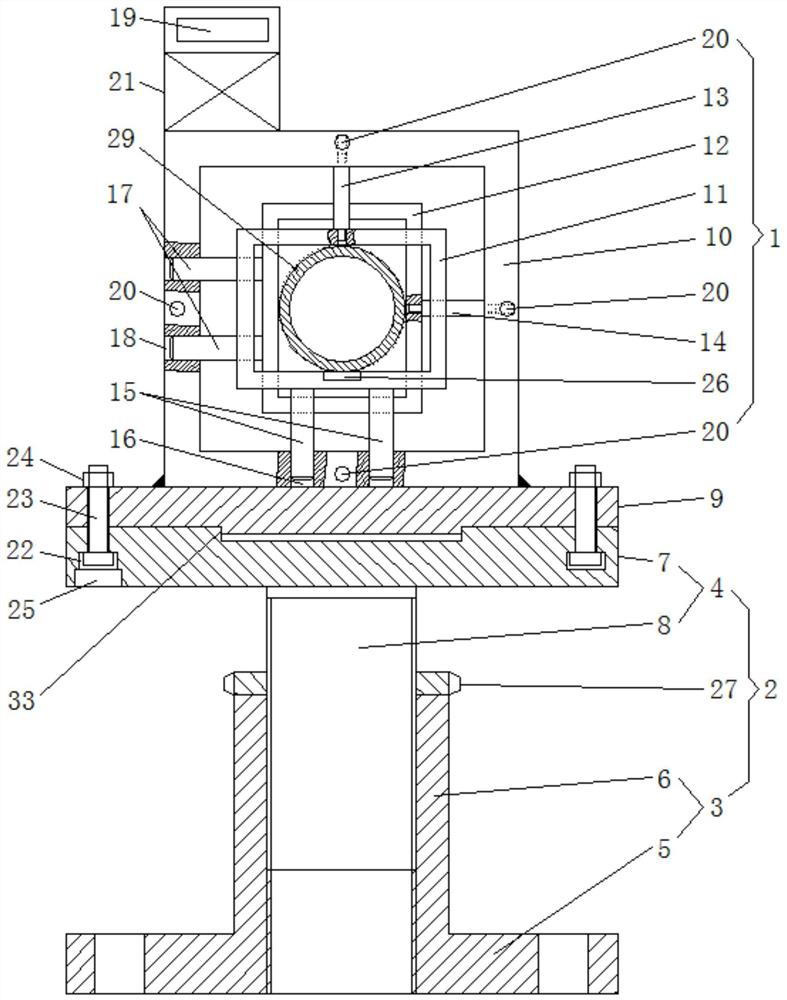

[0036] like Figures 1 to 2 Shown is an embodiment of a small-diameter branch pipe welding positioning tool of the present invention, including a height adjustment assembly 1 and a stress monitoring assembly 2 arranged on the height adjustment assembly 1 for dynamically monitoring the welding stress of the small-diameter branch pipe 29, the The height adjustment assembly 1 includes a fixed base 3 and a lifting base 4 connected to the fixed base 3 for installing and adjusting the height of the small-diameter branch pipe 29; The threaded seat 6 at the central position, the threaded seat 6 is provided with a threaded hole along the vertical central axis of the threaded seat 6; the lifting seat 4 includes a first flange 7 and is erected on the first method The threaded rod 8 at the center position of the lower end of the blue plate 7 is matched with the threaded hole.

[0037]Preferably, the stress monitoring assembly 2 includes a second flange 9 and a large rectangular frame 10 ...

Embodiment 2

[0049] A positioning method for a small-diameter branch pipe welding positioning tool, comprising the following steps:

[0050] (1) Tool arrangement: according to the relative positional relationship between the small-diameter branch pipe 29 and the main pipe 28 after assembly, the welding positioning tool for positioning the small-diameter branch pipe 29 and a pair of V-shaped irons 30 for positioning the main pipe are arranged on the working platform 31, After confirming that the relative positions of the welding positioning tool and the pair of V-shaped irons 30 are accurate, the welding positioning tool and the pair of V-shaped irons 30 are respectively fixed to the working platform 31;

[0051] (2) tooling adjustment: adjust the height of the welding positioning tooling so that the center height of the inner frame of the first small rectangular frame 11 on the welding positioning tooling is consistent with the center height of the main pipe 28;

[0052] (3) Positioning of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com