Porous nitrogen-doped carbon nanofiber dispersed nickel and molybdenum phosphide photocatalyst as well as preparation and application thereof

A nitrogen-doped carbon and nanofiber technology, applied in the field of photocatalytic materials, can solve the problems of poor selectivity of reduction products, easy recombination of photogenerated carriers, and few surface active sites, and achieve rapid transfer of artesian carriers and high specific surface area , High reduction of CO2 performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

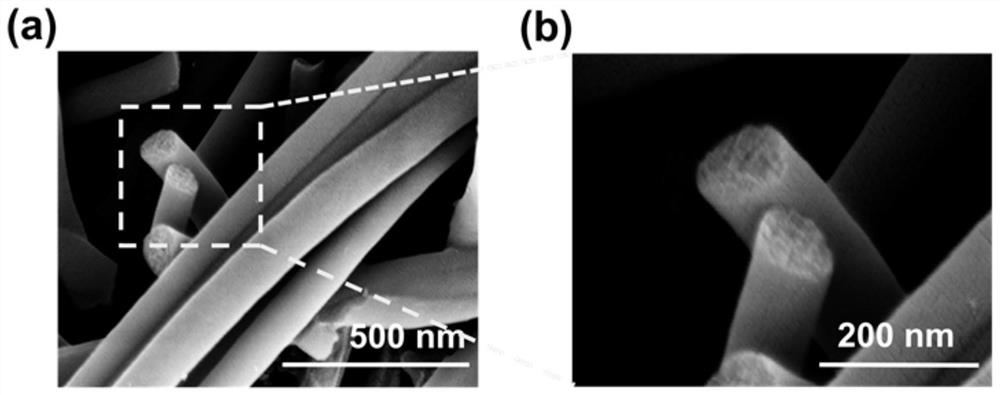

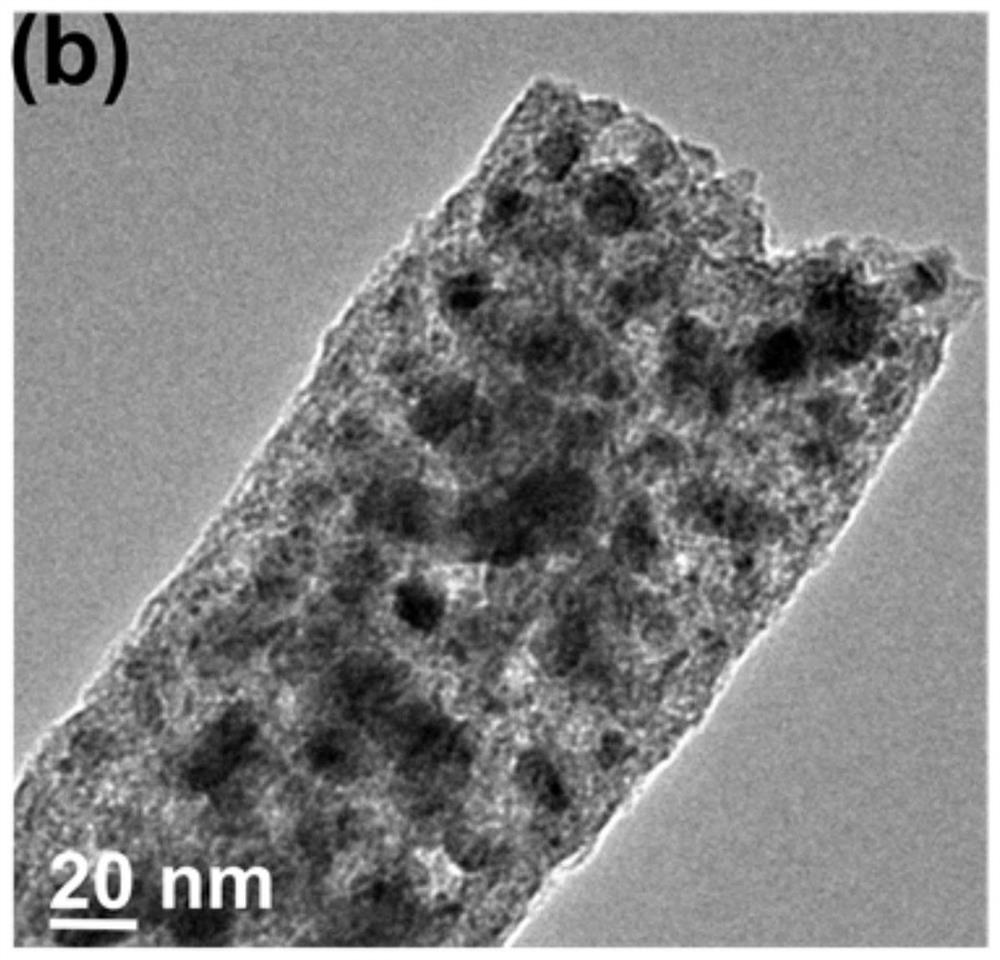

[0069] Dispersed nickel and molybdenum phosphide nanoparticles photocatalyst in a porous nitrogen-doped carbon nanofiber mainly contains six main elements of Mo, Ni, P, O, C and N, and is prepared by a method comprising the following steps:

[0070] (1) Preparation of Mo-Ni spinning solution

[0071] Take 2mmol MoCl respectively 5 , 0.06mmol Ni(NO 3 ) 2 ·6H 2 O and 400mg PS were dissolved in 5mL DMF, and after the above reagents were dissolved, 0.5g PAN was added, and heated and stirred in an oil bath at 60°C to dissolve.

[0072] (2) Preparation of Mo-Ni carbon fiber membrane

[0073] Transfer the above Mo-Ni spinning liquid into a syringe, and use the electrospinning equipment to carry out electrospinning. During the electrospinning process, the temperature in the control room is 25°C, the ambient humidity is not more than 50%, and the negative high voltage is -3kV. The positive high voltage was 13kV, and the liquid feeding rate of the spinning solution was 0.004mL / min;...

Embodiment 2

[0096] Dispersed nickel and molybdenum phosphide nanoparticles photocatalyst in a porous nitrogen-doped carbon nanofiber mainly contains six main elements of Mo, Ni, P, O, C and N, and is prepared by a method comprising the following steps:

[0097] (1) Preparation of Mo-Ni spinning solution

[0098] Take 2mmol MoCl respectively 5 , 0.12mmol Ni(NO 3 ) 2 ·6H 2 O and 400mg PS were dissolved in 5mL DMF, after the above drug was dissolved, 0.5g PAN was added, and placed in a 60°C oil bath, heated and stirred to dissolve.

[0099] (2) Preparation of Mo-Ni carbon fiber membrane

[0100] Transfer the above Mo-Ni spinning liquid into a syringe, and use the electrospinning equipment to carry out electrospinning. During the electrospinning process, the temperature in the control room is 25°C, the ambient humidity is not more than 50%, and the negative high voltage is -3kV. The positive high voltage was 13kV, and the liquid feeding rate of the spinning solution was 0.004mL / min; fina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com