Plate-shaped fuel element outlet large-space jet flow visualization experiment device

A fuel element and experimental device technology, applied in nuclear reactor monitoring, climate sustainability, reactors, etc., can solve problems such as the limitation of the flow field measurement range and the influence of the experimental device on the flow field structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

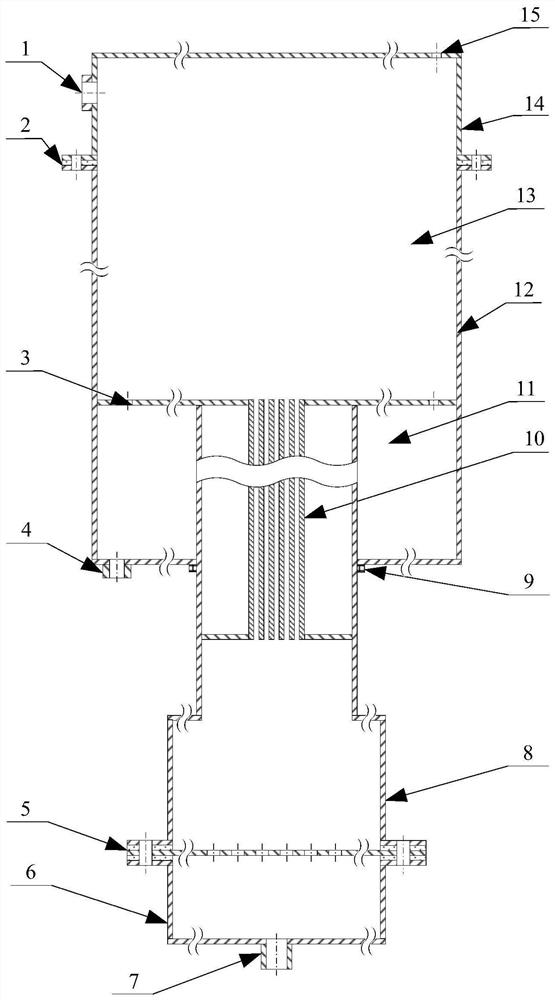

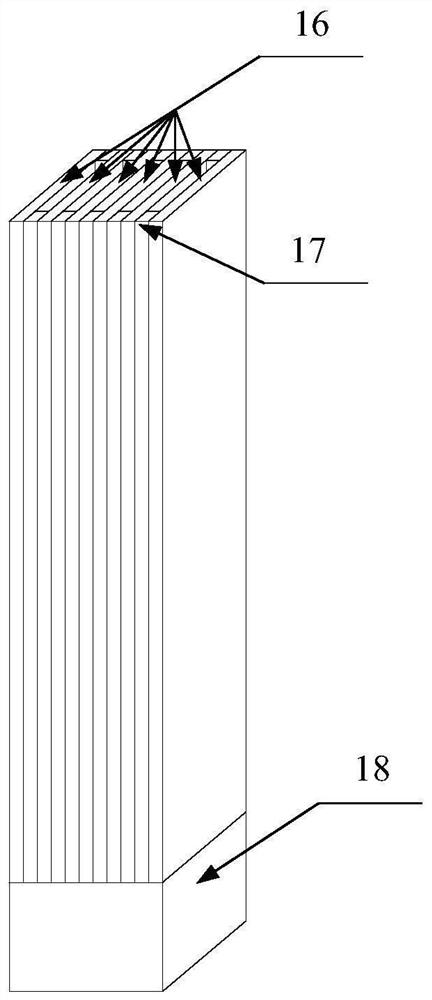

[0018] to combine figure 1 , is a cross-sectional view of the large-space jet flow visualization device at the outlet of the plate-shaped fuel element of the present invention. The test device is entirely made of transparent plexiglass material, and its height and side walls have negligible influence on the mainstream of the jet flow, and can be more accurately restored. The flow field information realizes the full-field visual collection of the multi-jet flow from separation to convergence, mixing and flow development. The experimental device includes water outlet pipe 1, flange rubber gasket 2, partition plate with water replenishment hole 3, low point water discharge valve 4, flow distribution orifice plate 5, inlet chamber 6, water inlet hole 7, parallel flat channel buffer Chamber 8, anti-leakage plexiglass strip 9, multi-slit p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com