Virtual sensor backup control method and modeling method and device

A technology of virtual sensors and control methods, applied in heating and ventilation control systems, heating methods, mechanical equipment, etc., to solve problems such as system failure to operate normally

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

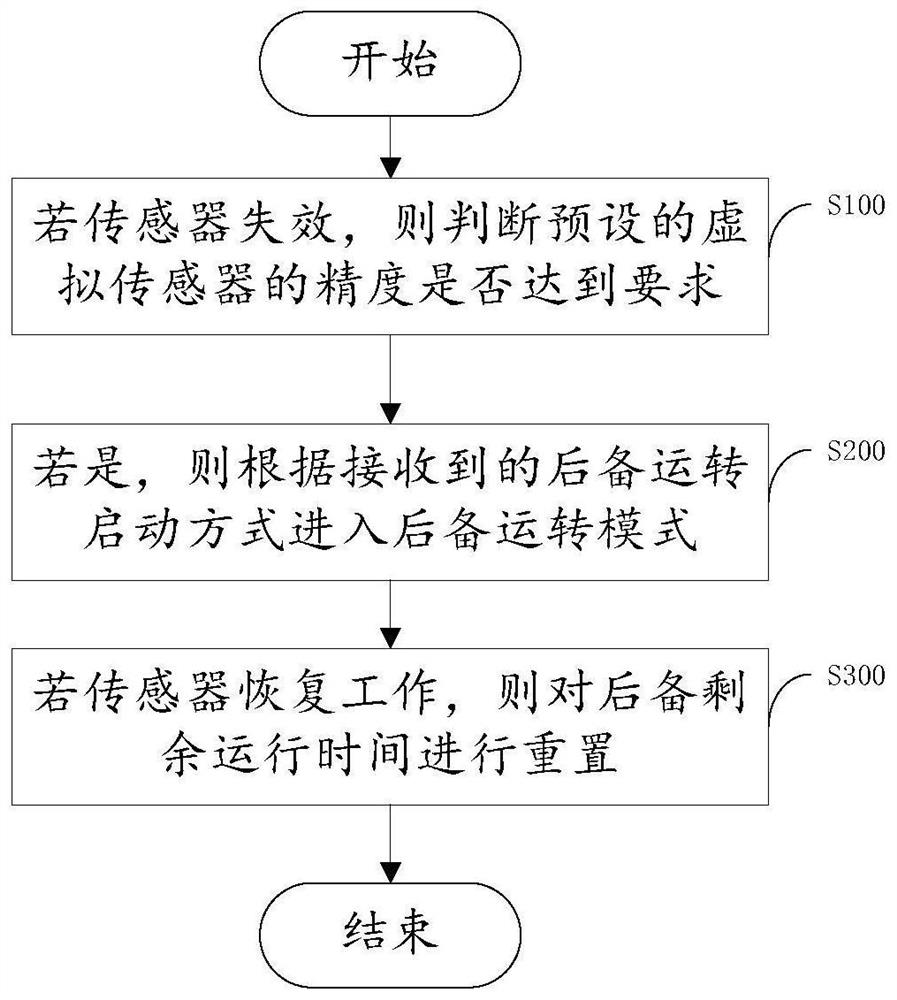

[0086] Please see figure 1 , figure 1 It is a flow chart of a virtual sensor backup control method provided by the embodiment of the present application. This method builds a virtual sensor into the system, and corrects the virtual sensor calculation model through actual operating data (components and installation environment will lead to model differences). Manual entry and automatic entry), carry out backup operation, and reset the backup operation time after the sensor recovers, so as to solve the problem that the system stops running after the sensor fails. The method specifically includes the following steps:

[0087] Step S100: If the sensor fails, then judge whether the accuracy of the preset virtual sensor meets the requirements;

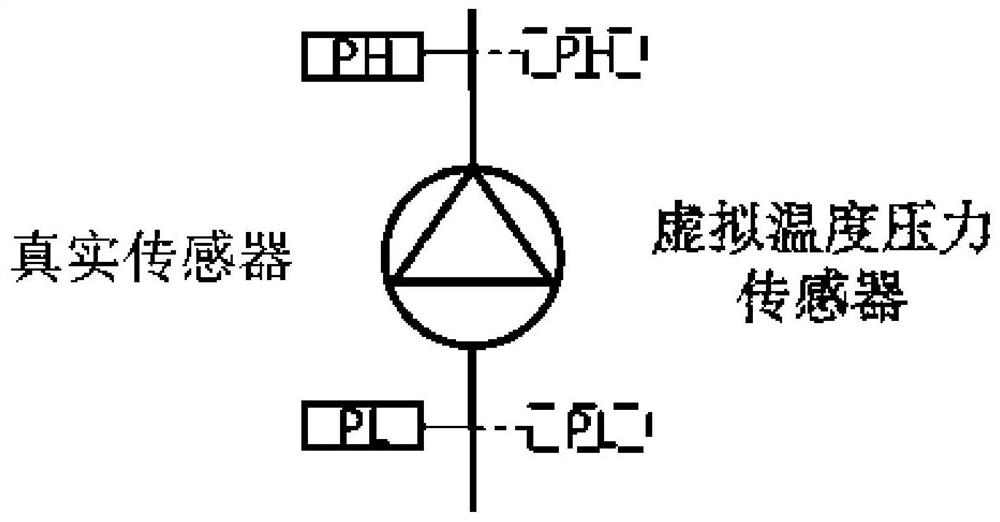

[0088] First, it is necessary to construct the sensor model corresponding to the virtual sensor, such as figure 2 As shown, it is a flow chart of constructing a virtual sensor, which specifically includes the following steps:

[0089] ...

Embodiment 2

[0146] The embodiment of the present application provides a virtual sensor backup control device, such as Figure 9 Shown is the structural block diagram of the virtual sensor backup control device, which includes:

[0147] The accuracy judging module 100 is used for judging whether the accuracy of the preset virtual sensor meets the requirements if the sensor fails;

[0148] The backup start module 200 is used to enter the backup operation mode according to the received backup operation startup mode if the accuracy of the virtual sensor meets the requirements;

[0149] The reset module 300 is configured to reset the remaining running time of the backup if the sensor resumes working.

[0150] Among them, such as Figure 10 As shown, it is a block diagram of the overall structure of the virtual sensor backup control device, and the accuracy judgment module 100 includes:

[0151] Calculation module 101, for calculating the virtual sensor value;

[0152] An error module 102, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com