Construction method of post-cast strip floor slab with independent support

A construction method and technology of post-pouring tape, which is applied in the fields of formwork/formwork/work frame, construction material processing, and on-site preparation of building components, which can solve the problems of high construction cost and long service life of formwork

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

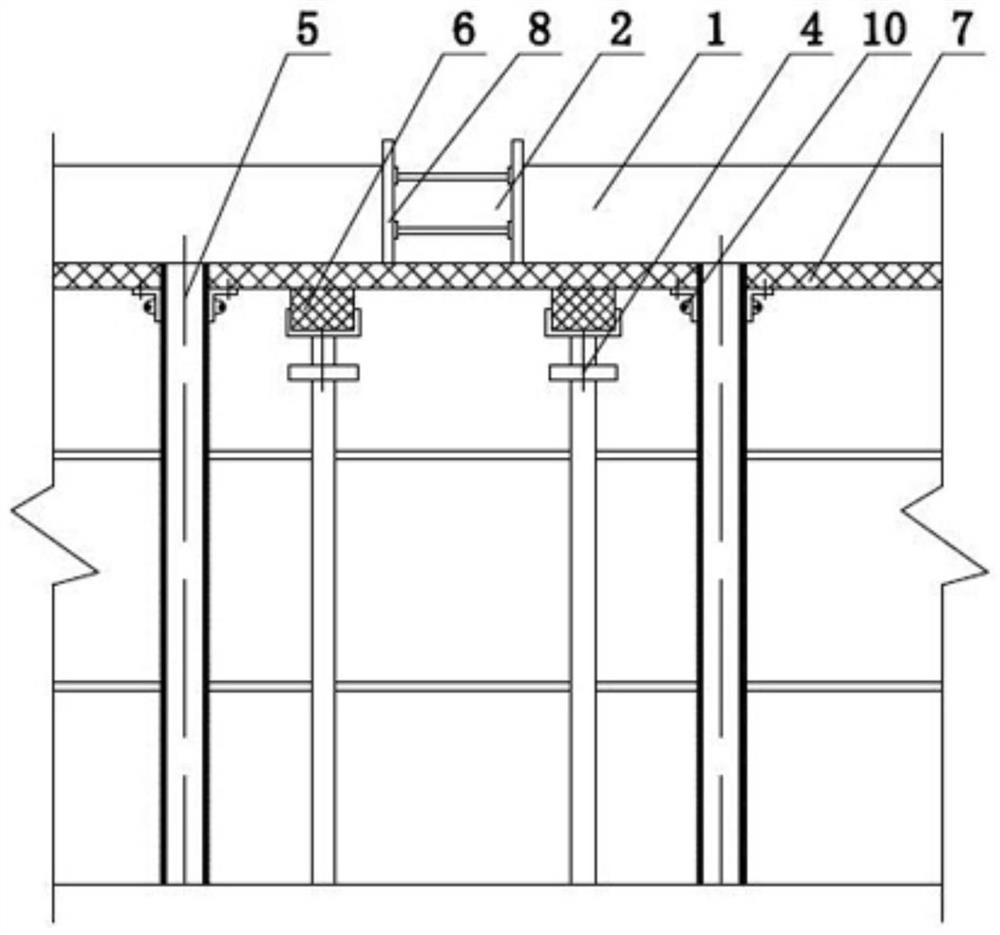

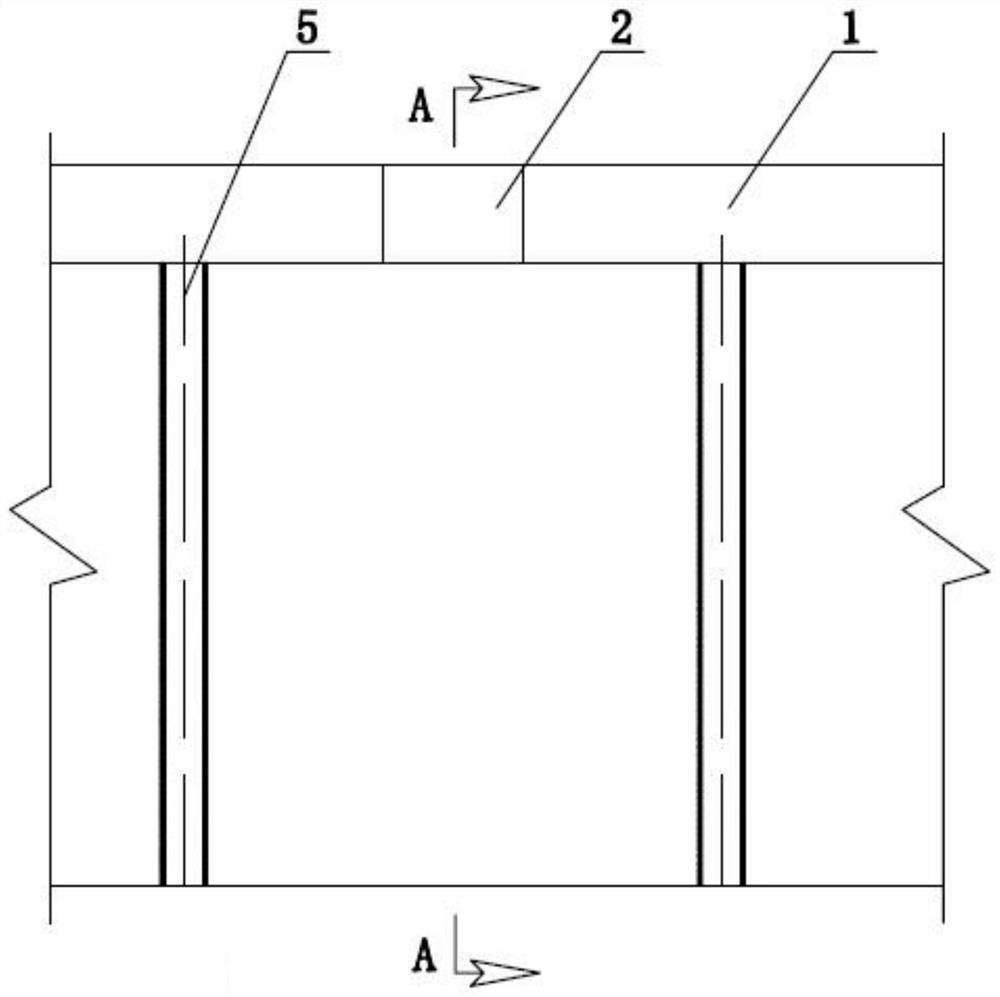

[0021] Referring to the accompanying drawings, a construction method with independently supported post-cast belt floor, said independently supported construction method is realized by the following steps.

[0022] Step 1. Set up the vertical support system 4 of the floor 1 and the bottom formwork 7 of the post-cast belt 2 .

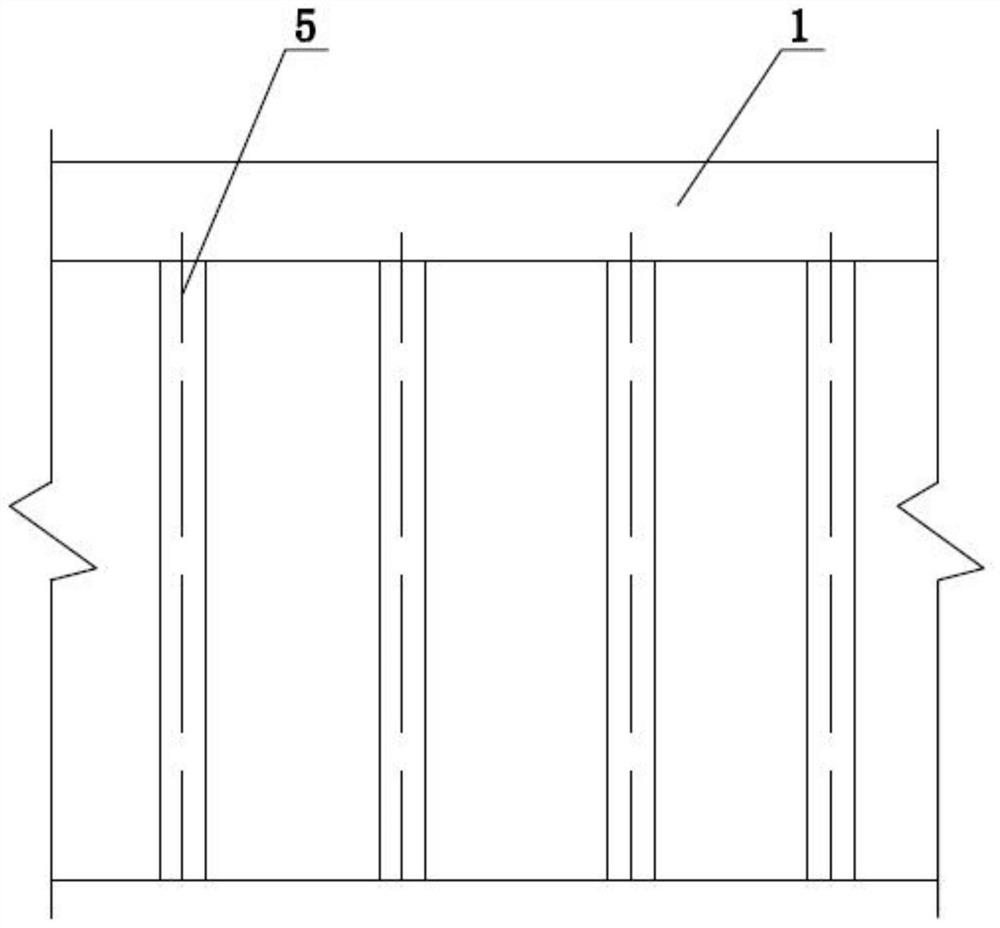

[0023] Step 2. In the vertical support system 4, at the connecting end of the floor 1 and the post-casting belt 2, a group of vertical supporting PVC pipes 5 are evenly distributed along the length direction of the post-casting belt 2 according to the design distance.

[0024] A group of vertical supporting PVC pipes 5 are connected and fixed with the vertical supporting system 4. The purpose of setting up the vertical supporting PVC pipes 5 is to simultaneously pour the auxiliary supporting columns at the connection end of the floor 1 and the post-cast belt 2 when the concrete of the floor 1 is poured. .

[0025] Step 3. On the vertical support system 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com