A light prefabricated steel structure building

A prefabricated, steel structure technology, applied in the direction of construction, building structure, etc., can solve the problems of cumbersome operation process and achieve the effect of improving installation efficiency, stability and light structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

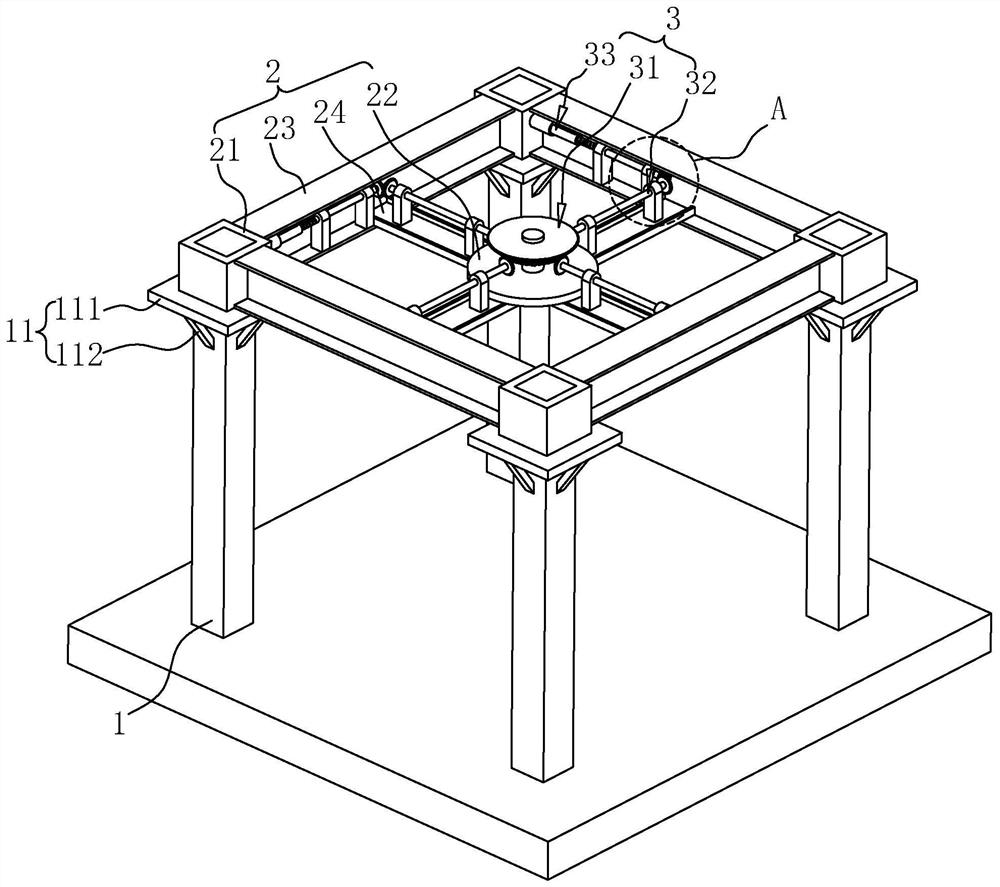

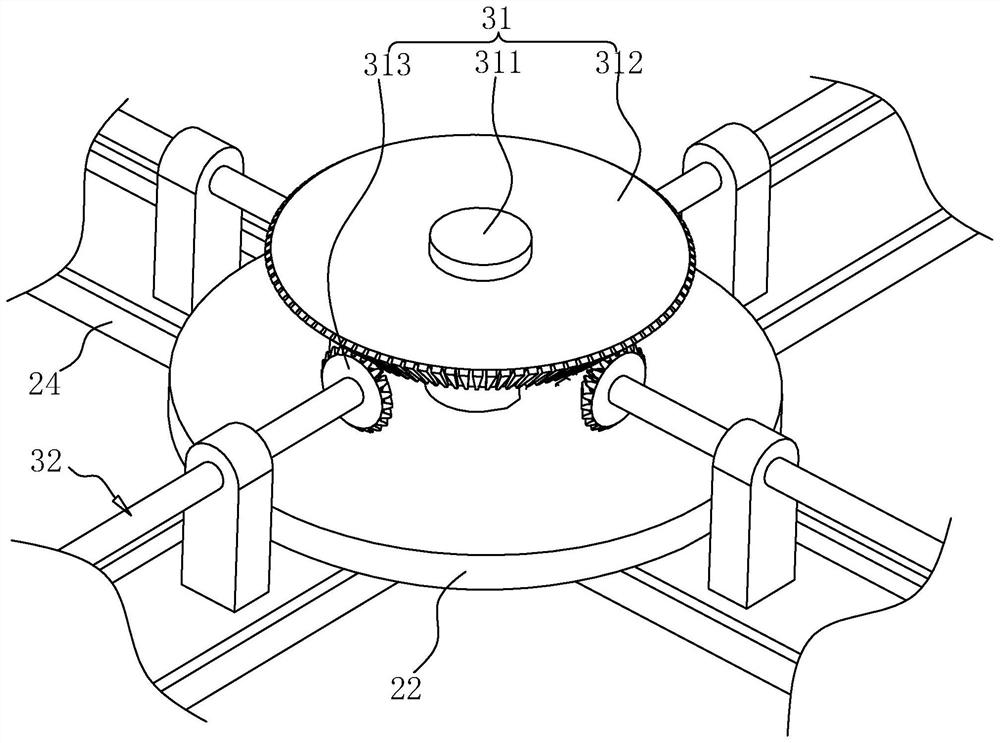

[0039] The embodiments of the present application disclose a light-weight prefabricated steel structure building. refer to figure 1 , the structural building includes a number of uprights 1 and a beam frame 2 arranged on the uprights 1, wherein, in this embodiment, the specific number of the uprights 1 is four, and the four uprights 1 are arranged in the vertical direction, and are arranged in the vertical direction. In a rectangular arrangement, the bottom end of the upright column 1 can be fixedly installed at the foundation. The installation method of the upright column 1 is in the prior art, and will not be repeated here.

[0040] The column 1 is used for supporting the beam frame 2 . Specifically, a supporting platform 11 is provided on the top of the column 1 , wherein the supporting platform 11 includes a supporting plate 111 and a reinforcing rod 112 . The support plate 111 is arranged in the horizontal direction, and the support plate 111 is provided with a socket ho...

Embodiment 2

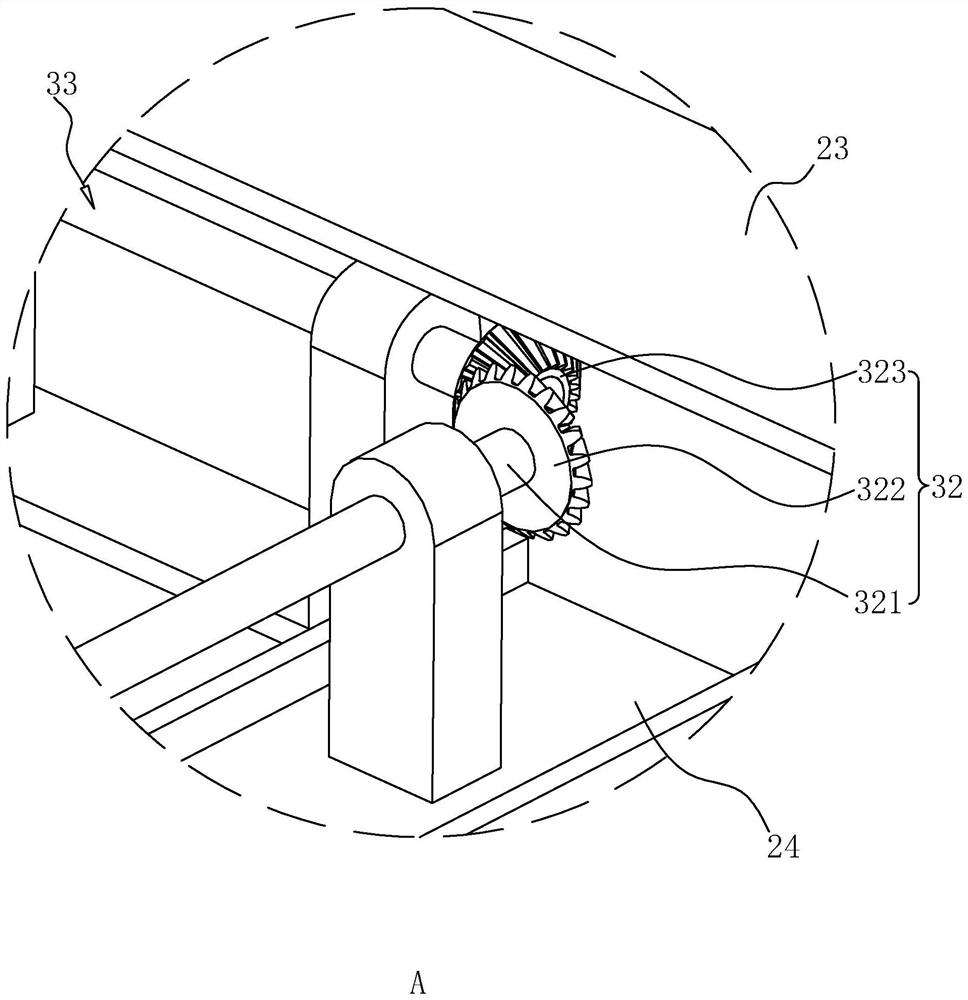

[0059] refer to Figure 5 , the difference between this embodiment and Embodiment 1 is that the structural building also includes a buckling assembly 4 adjacent to the input shaft 311 , specifically, the buckling assembly 4 is arranged on the installation platform 22, The input shaft 311 is locked and fixed, so as to reduce the possibility of the input shaft 311 shaking and being offset and loose when the socket portion 21 and the upright column 1 are locked.

[0060] Specifically, the snap-fit assembly 4 includes a first clamping portion 41 and a second clamping portion 42 . The first clamping portion 41 and the second clamping portion 42 are respectively slidably connected to the beam frame 2 . The top is recessed from the outside to the inside and is provided with a chute 221 , and the chute 221 is adjacent to the input shaft 311 .

[0061] In addition, the first clamping portion 41 includes a first connecting arm 411, a second connecting arm 412 and a first arc-shaped c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com