Transverse moving walking track of railway beam moving trolley

A technology for walking rails and moving beam trolleys, which is applied in the directions of rails, movable rails, roads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

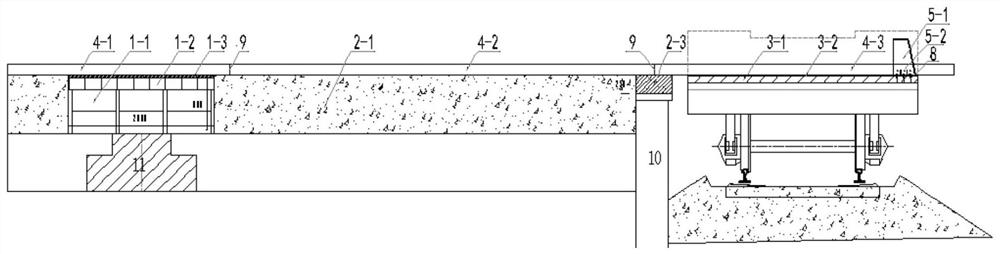

[0024] A slideway rail 4 for a railway beam-moving trolley laterally moving a traveling track. The slideway rail 4 includes a detachable slideway steel rail 4-1, a fixed slideway steel rail 4-2 and a movable slideway steel rail 4-3. The butt joint of road rail 4-1, fixed slide rail 4-2 and mobile slide rail 4-3 is connected with splint 9.

[0025] The fixed slide rail 4-2 is horizontally installed on the outside of the existing line, and a flatbed car is arranged on the existing line, and the mobile slide rail 4-3, the mobile slide rail 4-3 and the fixed slide rail 4-2 are installed on the flat cart butt ends. The other end of the fixed slide rail 4-2 is docked with the detachable slide rail 4-1 within the walking range of the gantry crane.

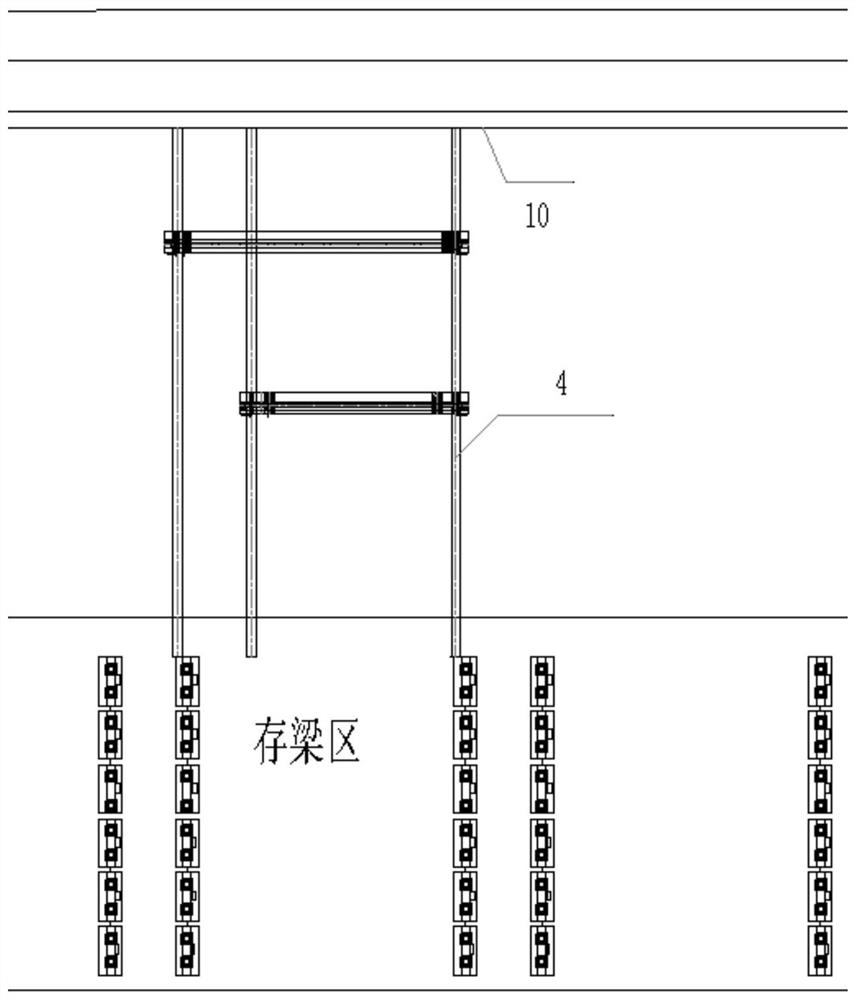

[0026] The slide rail 4 is provided with three, and the slide rail 4 in the middle is used as a shared track, and has different spacings with the other two slide rails 4, so as to adapt to bridge transportation of different sizes.

[00...

Embodiment 2

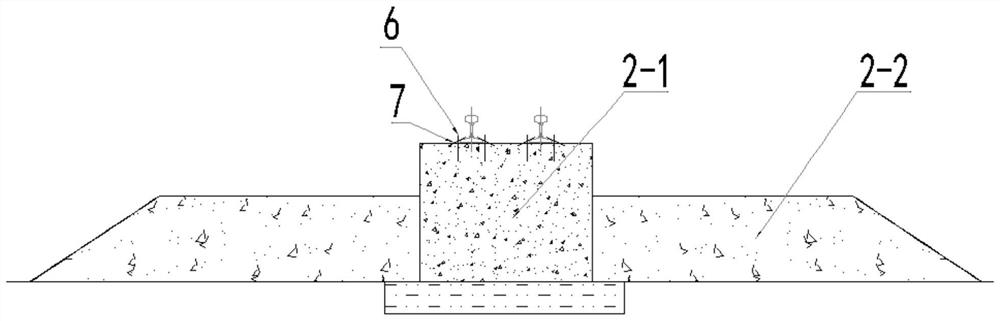

[0033] Such as Figure 1-Figure 4 As shown, the rail system for the lateral movement of the railway beam-moving trolley includes the detachable slideway foundation 1, the fixed slideway foundation 2, the mobile slideway foundation 3 installed on the road flat car, the slideway rail 4 and the buffer device 5 composition. The detachable slideway 1 within the running line of the gantry crane is arranged vertically to the center line of the gantry crane; the fixed slideway 2 is arranged to the edge of the platform wall 10; The track rail 4 adopts P50 steel rail, and a single slideway adopts double rails with a rail spacing of 400mm; the buffer device 5 is welded at the end of the slideway by steel plates.

[0034] Preferably, the slideway rails 4 of the above-mentioned beam-moving trolley traverse the traveling track are provided with 3 pieces in total, the distance between the running slide rails of the 24m beam is 22m, the distance between the slideway of the 32m beam is 30m, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com