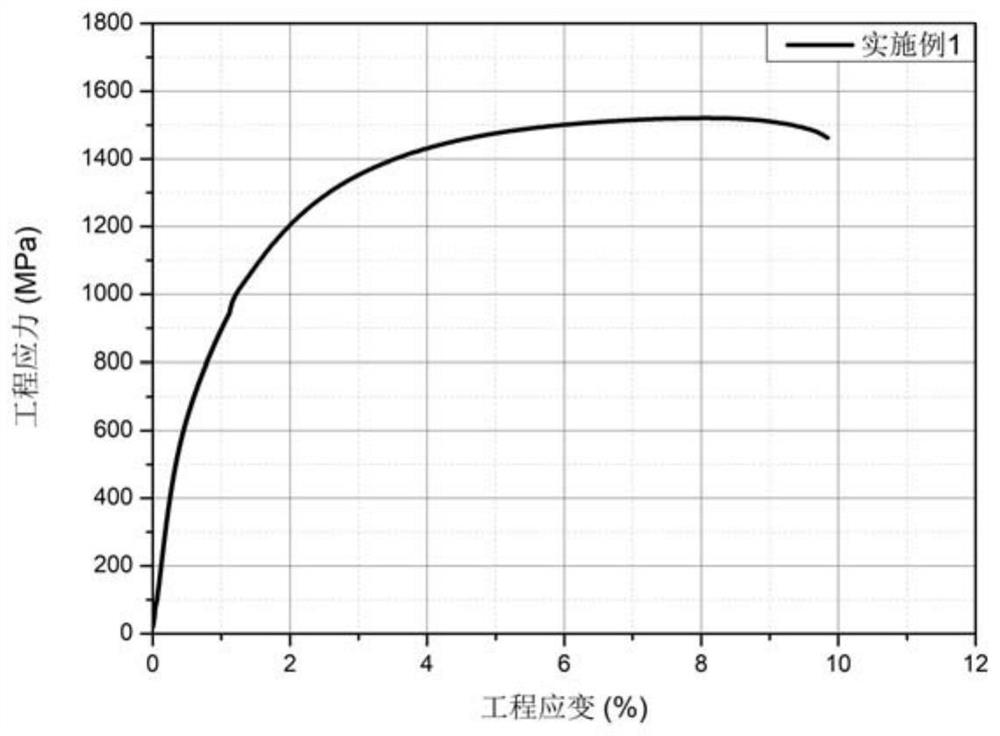

1.5gpa grade ultra-high-strength, high-plasticity, and high-hole-expansion DH steel plate and preparation method

An ultra-high-strength, high-plasticity technology, applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve difficult problems such as ultra-high strength, good ductility and formability, and poor product plasticity, so as to improve ductility and production Low cost, good impact energy absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further illustrated by the following examples.

[0041] In the embodiment of the present invention, smelting, continuous casting of medium and thin slabs, continuous hot rolling, pickling cold rolling, continuous annealing, and skinning are performed according to the component distribution ratio of the technical solution;

[0042] (1) Smelting: converter molten steel temperature 1650 ~ 1750 ℃;

[0043] (2) Continuous casting of medium and thin slabs: the casting temperature is 1600-1660 °C, and the thickness of the continuous casting slab is 100-170 mm.

[0044] (3) Hot continuous rolling: the temperature of the billet entering the furnace is 450-600°C, the heating temperature is 1140-1280°C, the rolling temperature is 1000-1150°C, the final rolling temperature is above 880°C, and the coiling temperature is 500-650°C;

[0045] The microstructure of the hot-rolled steel plate is ferrite + pearlite + bainite + cementite; the microstructure o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com