Pneumatic stable lifting positioning mechanism

A jacking and positioning mechanism, lifting and positioning technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of not being able to lift at the same time and lift smoothly, many repairs, and improper assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

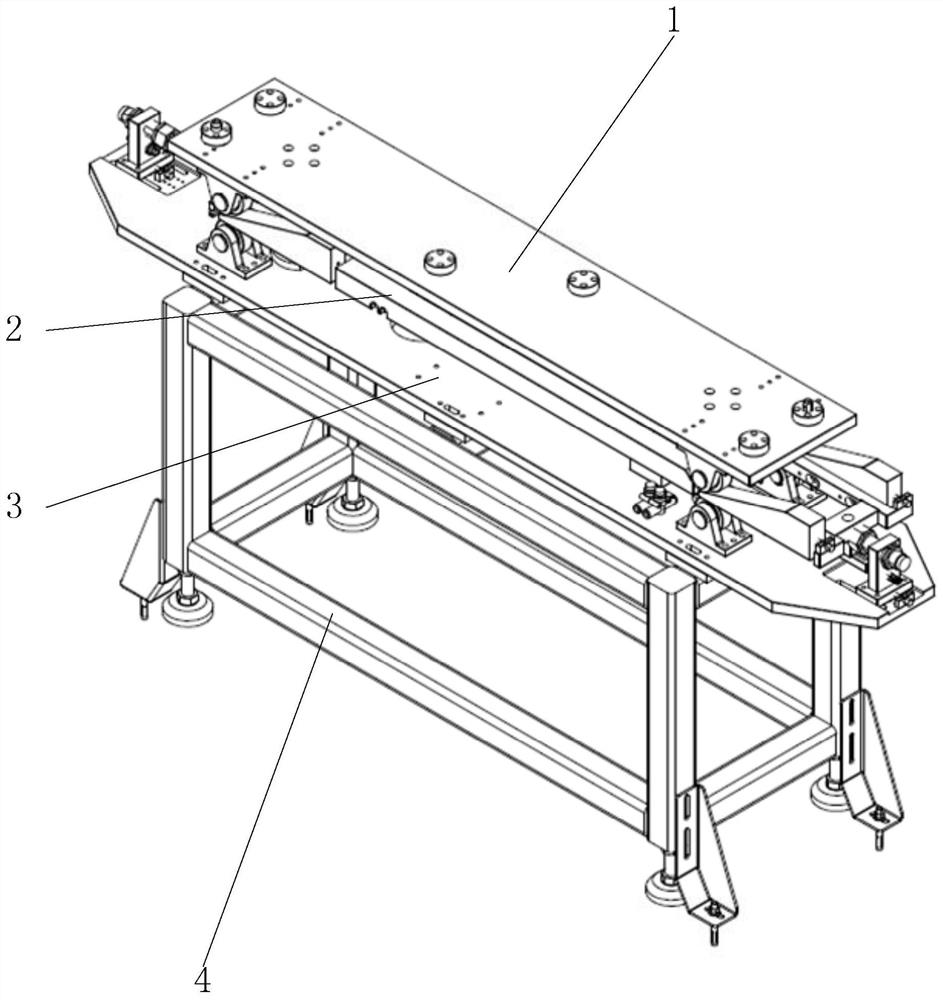

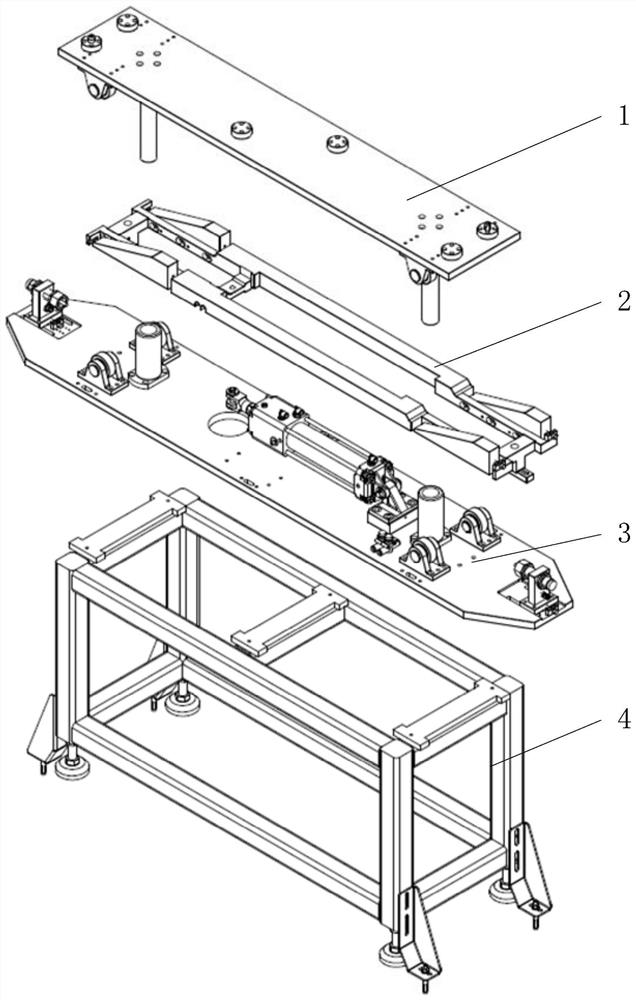

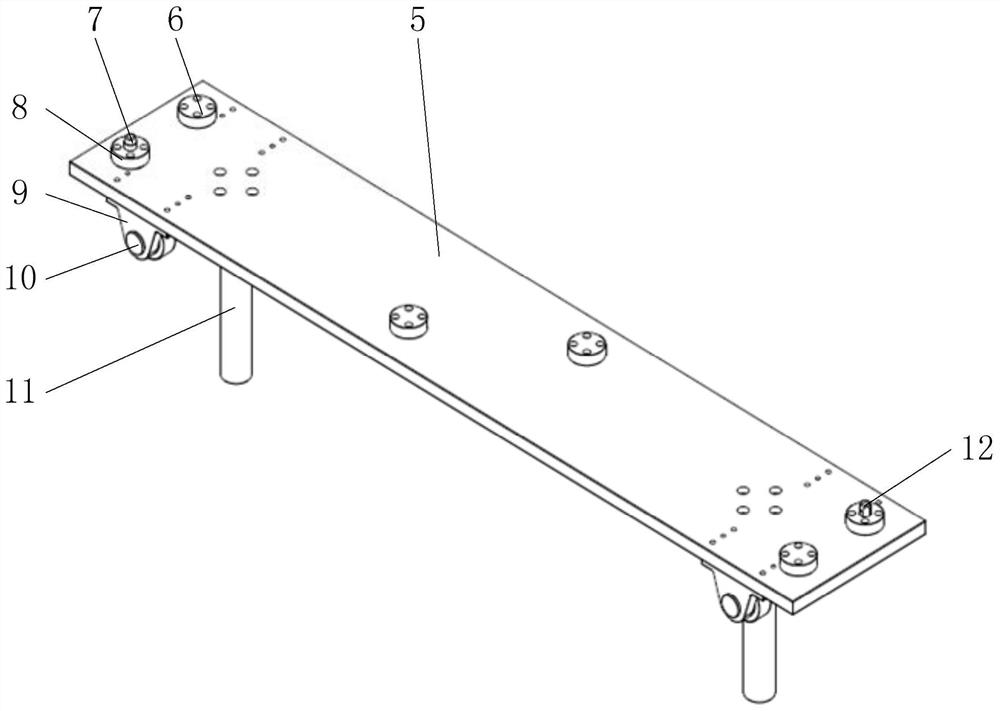

[0048] like Figure 1 to Figure 9 As shown, a pneumatic stable lifting and positioning mechanism includes a jacking and positioning mechanism 1, a connecting rod pushing block mechanism 2, a cylinder driving mechanism 3 and a fixed frame 4 from top to bottom, and the jacking and positioning mechanism 1 includes a jacking pallet 5. The upper roller 10 and the guide shaft 11, the bottom of the jacking plate 5 near the surrounding position are installed with the upper roller 10 through the upper roller fixing seat 9, and the connecting rod pushing block mechanism 2 includes a slider connecting rod 13, a cylinder Y-shaped Joint connecting block 14, forward inclined slide block 17 and rear inclined slide block 18, front end both sides of slide block connecting rod 13 are all equipped with forward inclined slide block 17, and the rear end both sides of slide block connecting rod 13 are all equipped with rear inclined slide block. Slider 18, the side of slider connecting rod 13 close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com