Optical sorting machine for magnetic steel of miniature disc type motor

A technology of micro-disc and sorting machine, applied in sorting and other directions, can solve problems such as low efficiency, labor, labor and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

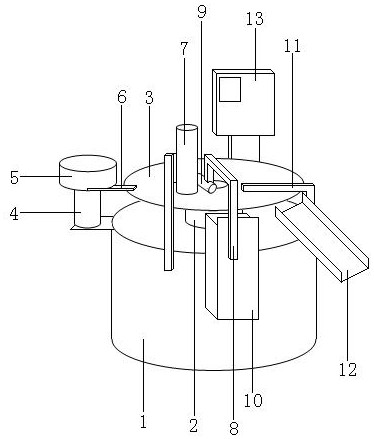

[0021] Now describe in detail the shape and structure of the present invention in conjunction with accompanying drawings and reference numerals:

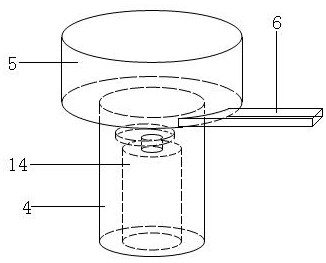

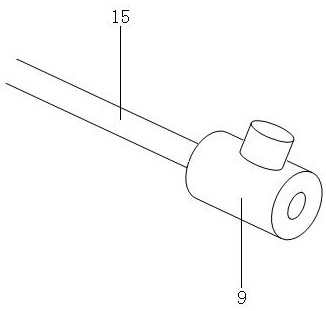

[0022] A kind of miniature disc motor magnetic steel optical sorting machine, it is characterized in that comprising, base 1, servo motor (DC12V / 100W) 2, glass tray 3, vibrating disc base 4, vibrating disc 5, discharge pipe 6, camera ( DC12V / 2A) 7, air valve bracket 8, electric control air valve (DC12V / 2A, 4kpa) 9, waste box 10, baffle plate 11, chute 12, control box 13, vibration motor (DC12V / 60W) 14, air supply pipe (4kpa) 15. Power supply (AC220V / 4A, DC12V / 40A) 16. Multi-channel controller (DC12V / 35A) 17. Display (DC12V / 2A) 18. Power cord (3x1.5mm²) 19;

[0023] The base 1 is cylindrical and vertically arranged on the ground, a cylindrical servo motor 2 is vertically arranged in the center of the top, and a disc-shaped glass tray 3 is horizontally arranged on the top of the central axis of the servo motor 2 through a disc-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com