Down jacket production equipment and method

A production equipment and down jacket technology, applied in the field of clothing production, can solve problems such as difficulty in controlling the uniformity of down surface wrapping, down deformation, and inability to guarantee the overall shape of down jackets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

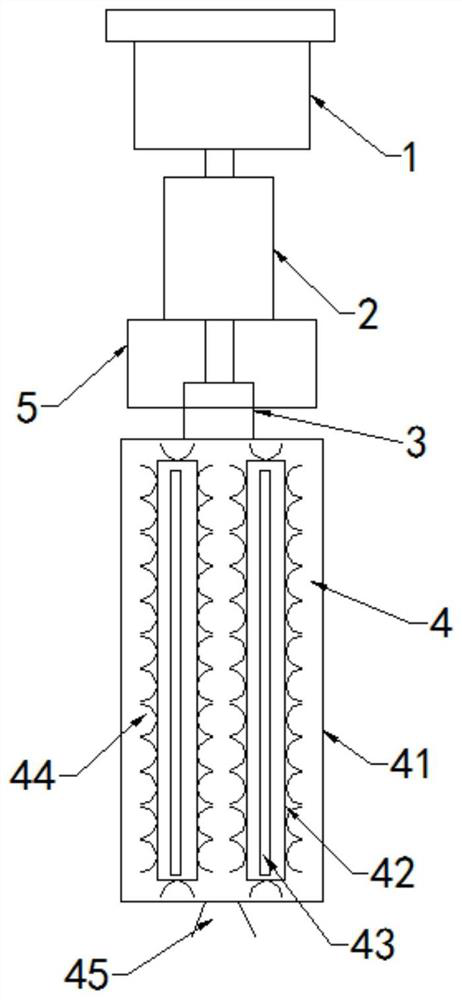

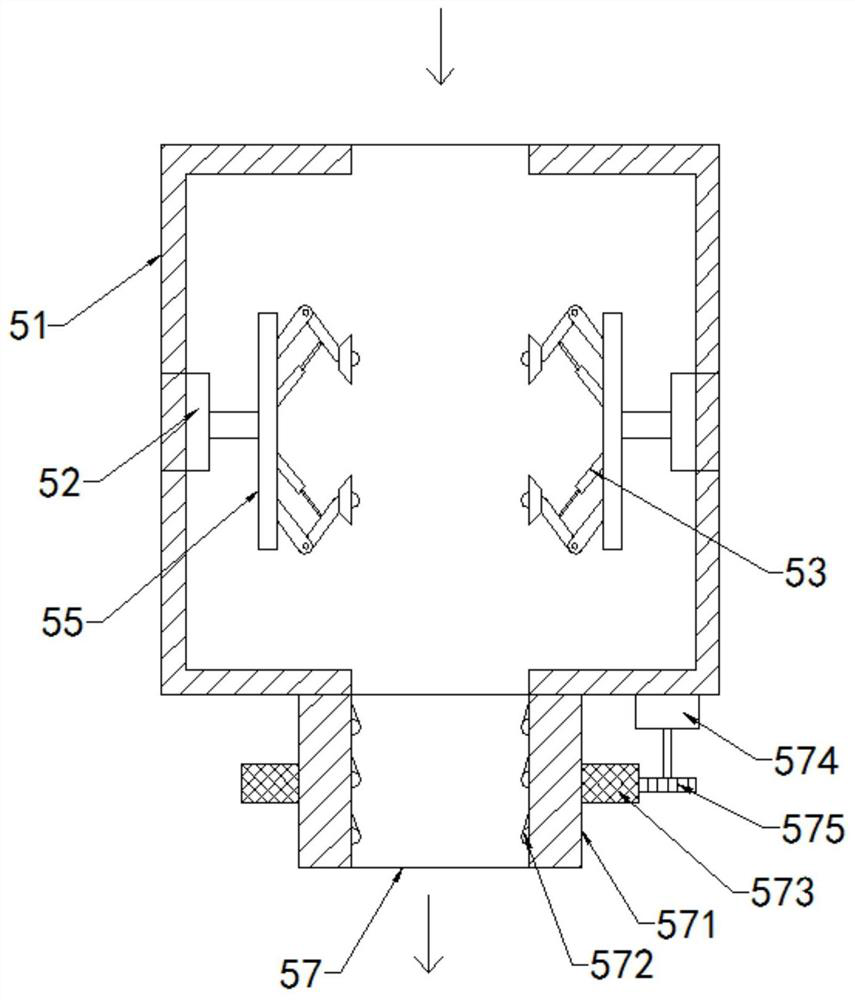

[0048] like figure 1 As shown, the present invention discloses a production equipment for down jackets. In the specific embodiment of the present invention, it includes a cutting unit for cutting the outer fabric according to the pattern, and cutting it into front panels, rear panels, sleeves and jackets. collar; a pretreatment unit, including a cleaning device, for cleaning the down to be treated; a treatment tank, for soaking and heating the cleaned down in alkaline water; an air-drying device, for air-drying the heated down for standby; The down ball preparation unit includes a compression device 1 for compressing the down; a shaping device 2 for wrapping and shaping the down with a water-soluble adhesive; a cutting device for cutting the compressed down into down balls; a drying device 4 for The shaped down balls are dried; the stuffing unit is used to evenly stuff the prepared down balls into the inner and outer layers of the down liner according to the number; the sewing...

Embodiment 2

[0071] The invention also discloses a production method of a down jacket, in a specific embodiment of the invention, comprising the following steps:

[0072] S1 cutting: Cut the fabric according to the pattern, and cut it into front panel, back panel, sleeves and collar;

[0073] S2 pretreatment: cleaning the down to be treated, soaking the cleaned down in alkaline water and heating, and air-drying the heated down for later use;

[0074] S3 shuttlecock preparation: including the following specific steps:

[0075] a Compression: compress the air-dried spare down through the compression device;

[0076] b. Shaping liquid: the compressed down enters the support tube of the shaping device, pulls the telescopic shaft, places the down between each pressing plate and conveys it downward, and then releases the spring of the telescopic shaft to generate elastic force so that the pressing plate is always squeezed from the side At the same time, start the transmission motor to rotate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com