Method for regulating and controlling smoke of double-cartridge heat not-burning smoke aerosol and device thereof

A heat-not-burn and pod technology, applied to tobacco and other fields, can solve the problems of low content stability, difficulty in meeting the physiological needs of smokers, and limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Such as figure 1 As shown, in the rich mode, the temperature of the first heating element and the second heating element are controlled according to the preset temperature at the same time, and the first and second cartridges are heated: in the first heating stage, the temperature of the dual heating elements is raised to 380°C at the same time , and maintain it until the 30th second; in the second heating stage, the dual heating elements are simultaneously cooled to 360°C for constant temperature, and the constant temperature time is maintained until the 270th second, and finally the heating is stopped. The heating time of the dual heating elements lasts a sum of 270s. The results of testing the glycerin and nicotine content of 9 puffs in rich mode are as follows: figure 2 shown.

Embodiment 2

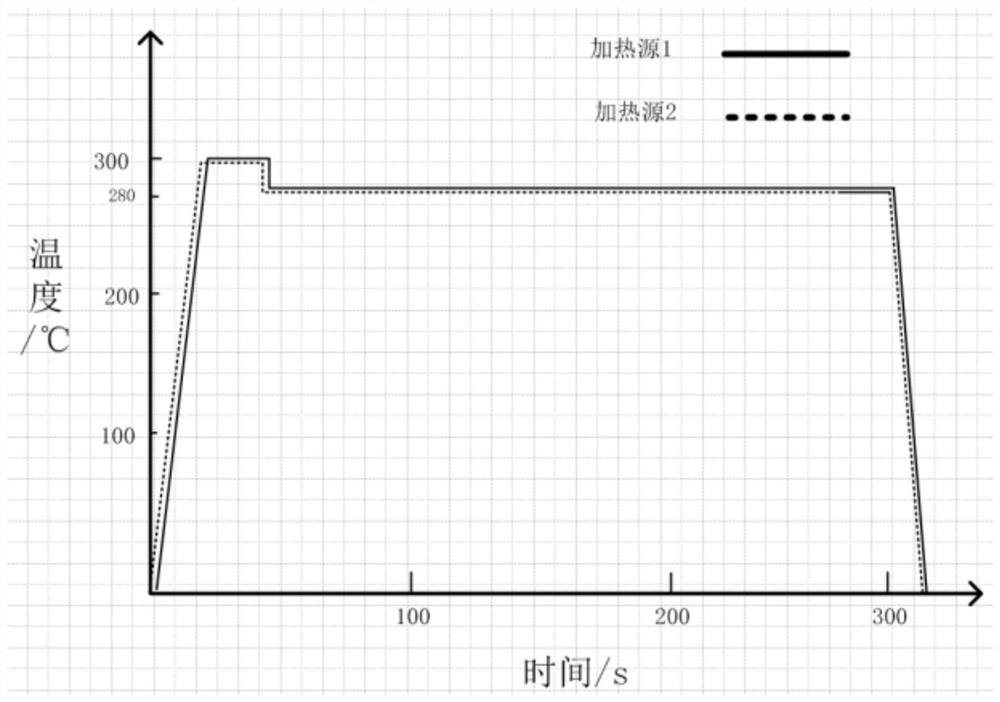

[0061] Such as image 3 As shown, when the consumer selects the standard mode and the expected number of puffs is 10 puffs, the standard mode is that the first heating element and the second heating element are controlled according to the preset temperature at the same time, and the first cartridge and the second cartridge are controlled at the same time. Heating by bombs: In the first heating stage, the temperature of the dual heating elements is raised to 300°C at the same time, and maintained until the first 30s. In the second heating stage, the dual heating elements are simultaneously cooled to 280°C for constant temperature, and the constant temperature time is maintained until the 300th second, and finally the heating is stopped. The heating time of the dual heating elements lasts a sum of 300s. The results of testing the glycerin and nicotine content of 10 puffs of standard mode smoking are as follows: Figure 4 shown.

Embodiment 3

[0063] Such as Figure 5 As shown, when the consumer selects the standard mode and the expected number of puffs is 14, the standard mode is that the first heating element and the second heating element are controlled according to the preset temperature at the same time, and the first cartridge and the second cartridge are controlled at the same time. Heating by bombs: In the first heating stage, the temperature of the dual heating elements is raised to 300°C at the same time, and maintained until the first 30s. In the second heating stage, the dual heating elements are simultaneously cooled to 280°C for constant temperature, and the constant temperature time is maintained until the 420th second, and finally the heating is stopped. The heating time of the dual heating elements lasts a sum of 420s. The results of testing the glycerin and nicotine content of 14 mouthfuls of standard mode smoking are as follows: Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com