Method for judging stability of heated cigarette raw material

A technology of stability and cigarettes, applied in the field of stability analysis of heating cigarette raw materials, can solve the problems of complicated operation, expensive and complicated instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

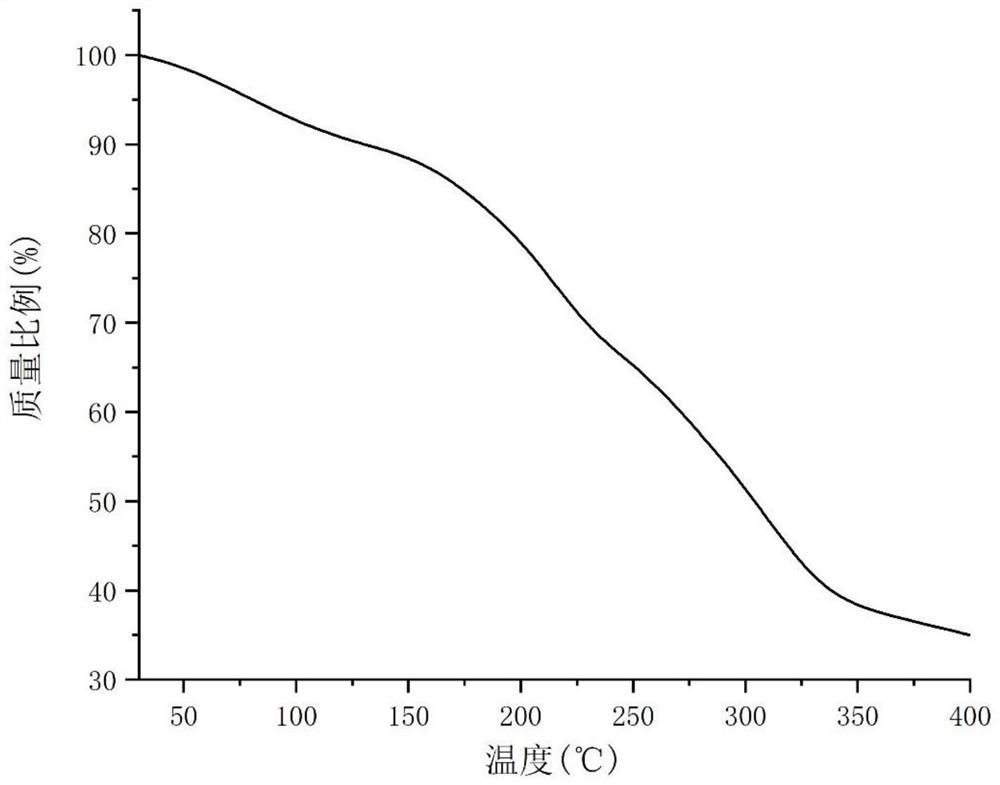

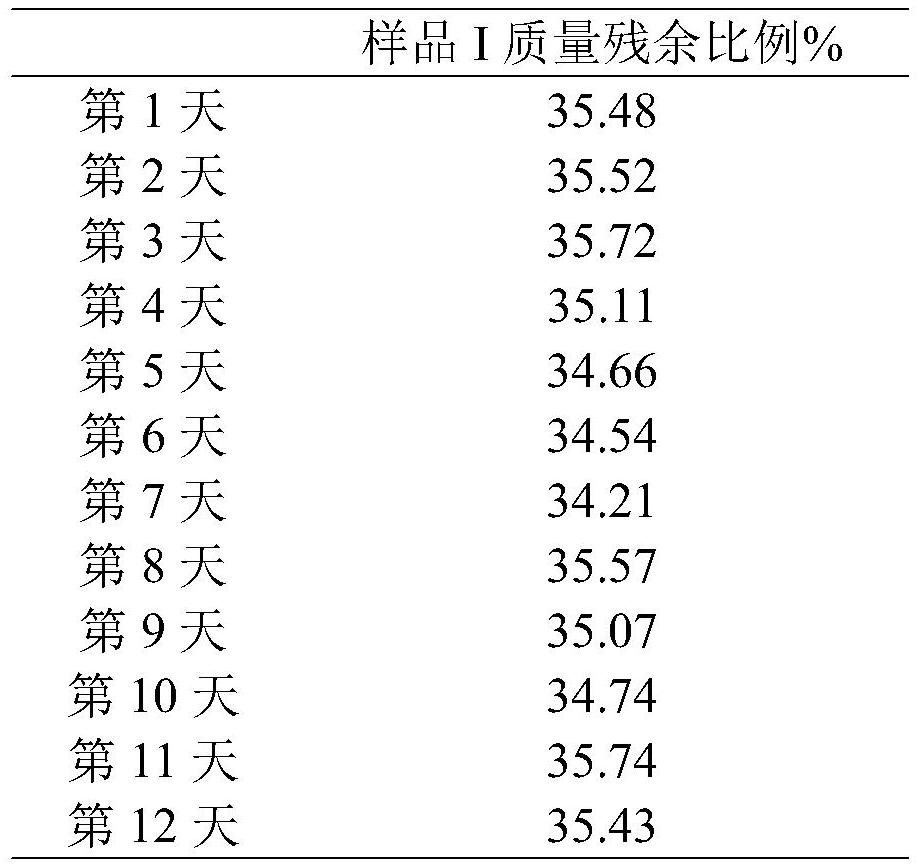

[0031] A method for judging the stability of heated cigarette raw materials described in the patent of the present invention is used for verification, and a reproducibility verification experiment is carried out for solid sample I. Weigh 10mg for detection, the gas environment is air, the flow rate is 20mL / min, the temperature range is 30-405°C, the heating rate is 10°C / S, the test is repeated 3 times or more, and the average value is calculated to analyze the sample quality at 400°C residual ratio. The results of repeated testing within the day are shown in Table 1; once a day, the results are shown in Table 2.

[0032] Table 1 sample 1 day repeated detection result

[0033]

[0034] Table 2 sample I repeated detection results during the day

[0035]

[0036]

[0037] It can be seen from Table 1 and Table 2 that the dispersion coefficients of the intra-day test results and day-time test results of this method are both less than 0.05, indicating that the method has ...

Embodiment 2

[0039] Using a method for judging the stability of heated cigarette raw materials described in the patent of the present invention to analyze the stability of reconstituted tobacco leaf samples of heated cigarette raw materials, and analyze the sample mass residual ratio at 400 ° C, the specific steps are as follows:

[0040] For solid sample 1 and sample 2, sample 10 times respectively, about 5g each time, cut into pieces, weigh 10mg for detection, the gas environment is air, the flow rate is 20mL / min, the temperature range is 30-405℃, and the heating rate is 10℃ / S, repeat the test 3 times or more, and calculate the average value, and calculate the dispersion coefficient for the test results of 10 samples, and the data are shown in Table 3.

[0041] Table 3 sample 1 and sample 2 thermogravimetric analysis results

[0042]

[0043] It can be seen from Table 3 that the dispersion coefficient of reconstituted tobacco sample 1 is less than 0.05, indicating that the stability ...

Embodiment 3

[0045] Using a method for judging the stability of heated cigarette raw materials described in the patent of the present invention to analyze the stability of heated cigarette raw material samples, and analyze the sample mass residual ratio at 350°C, the specific steps are as follows:

[0046] For heated cigarette liquid additive samples a, b and c, sample 12 times respectively, about 10g each time, shake and mix, weigh 20mg for testing, the gas environment is air, the flow rate is 30mL / min, and the temperature range is 30-410°C. The heating rate is 20°C / S, and the test is repeated 3 times or more to obtain the residual mass ratio of the sample, and calculate the average value. The dispersion coefficient is calculated for the test results of 20 samples. The data are shown in Table 4.

[0047] Table 4 Thermogravimetric analysis results of heated cigarette liquid additive samples a, b and c

[0048]

[0049] It can be seen from Table 4 that the dispersion coefficients of samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coefficient of variation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com