Rubber gasket type fixed caliper disc brake

A technology of disc brakes and rubber pads, applied in the direction of brake types, brake components, brake actuators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

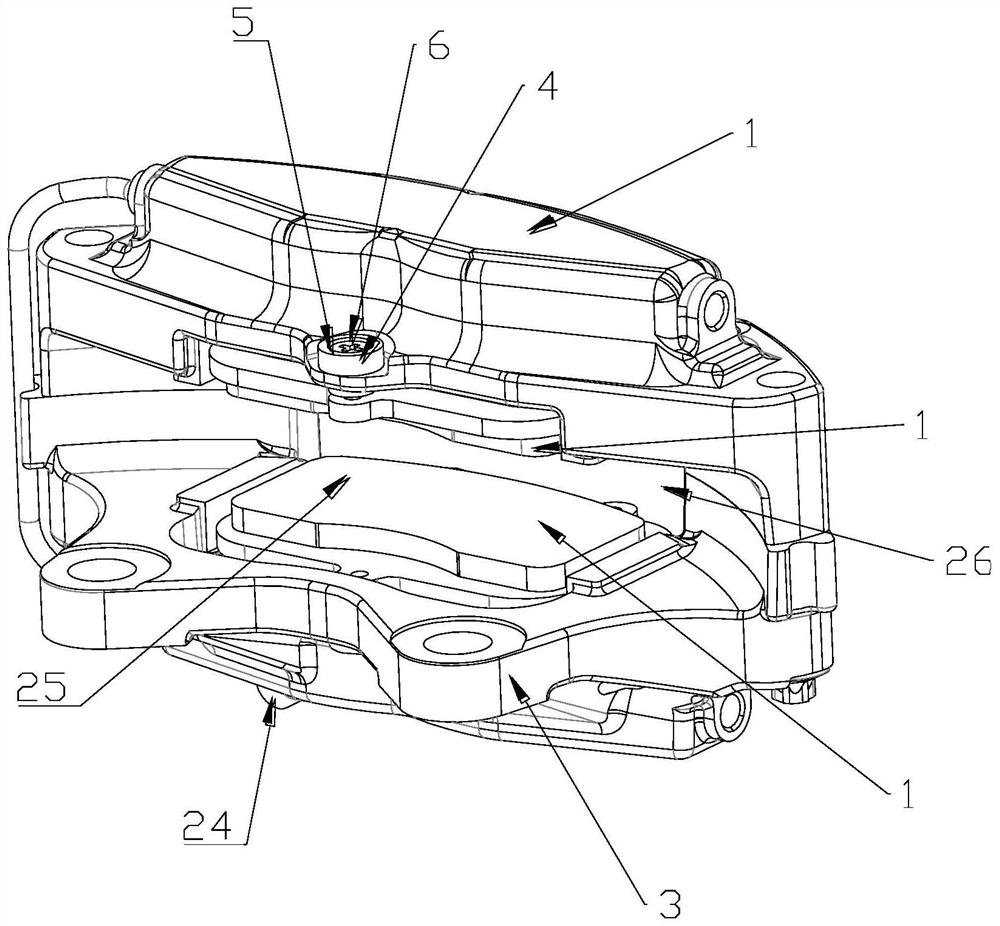

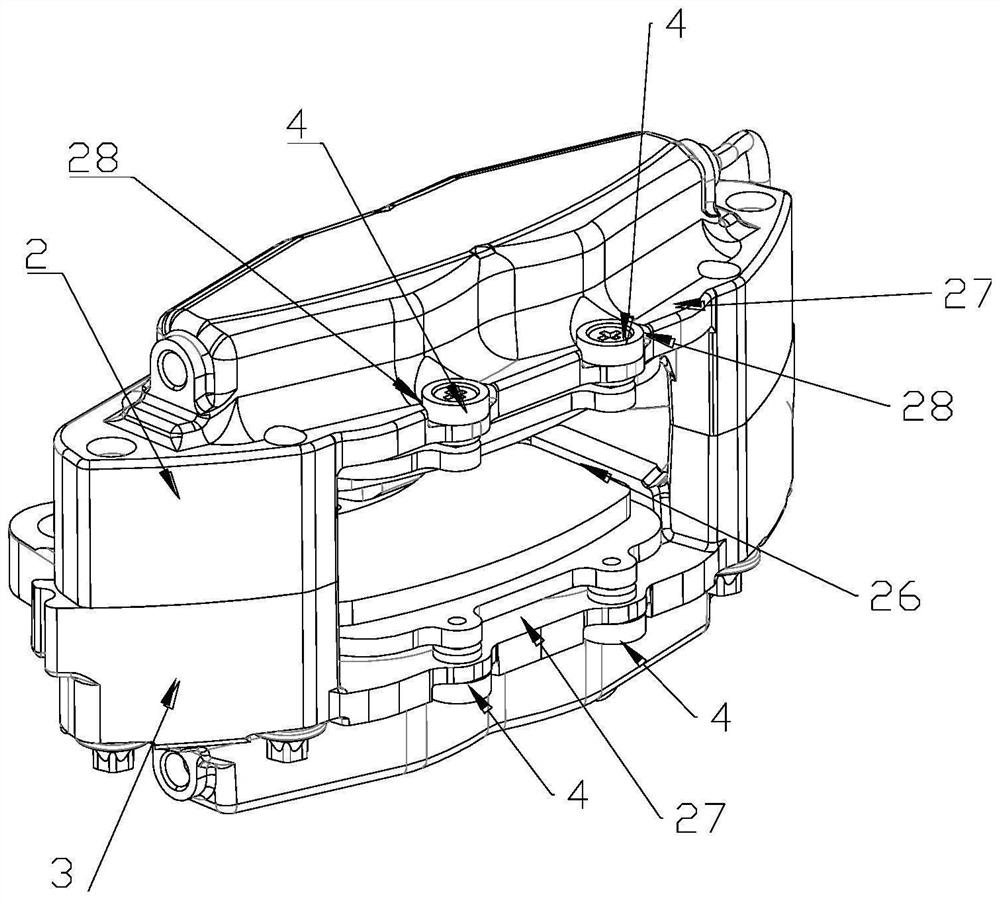

[0033] A rubber pad type fixed caliper disc brake, including a caliper body and a friction block 1 installed on the caliper body, wherein the caliper body includes an inner caliper body 2 and an outer caliper body 3, and the inner caliper body 2 and the outer caliper body 3 pass through Fixing bolts secure the connection.

[0034] A return component 4 is installed on the pliers body, and the friction block 1 is installed on the pliers body through the return component 4. The return component 4 includes an elastic deformation sleeve 5 and a fastening screw 6. A mounting hole 7 is provided on the pliers body, and the elastic deformation The sleeve 5 is installed in the installation hole 7, and the elastic deformation sleeve 5 includes an upper limit seat 8, a lower limit seat 9 and a connection sleeve 10 connecting the upper limit seat 8 and the lower limit seat 9, and the connection sleeve 10 is inserted in the installation hole 7, The upper limit seat 8 and the lower limit sea...

Embodiment 2

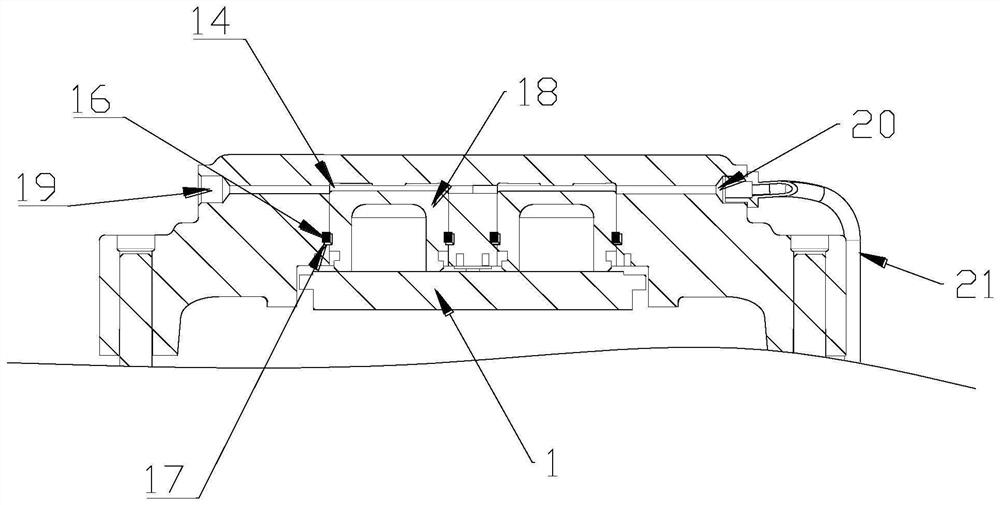

[0053] Compared with Embodiment 1, this embodiment also has the following schemes: in this embodiment, a piston chamber 14 is arranged in the caliper, a sealing groove 16 is arranged in the piston chamber 14, a rectangular sealing strip 17 is installed in the sealing groove 16, and the piston chamber 14 A piston 18 for pushing the friction block 1 to move is arranged inside, and the inner ring of the piston 18 and the rectangular sealing groove 16 has an interference fit. The caliper body includes an inner caliper body 2 and an outer caliper body 3, on which a piston 18 and a rectangular sealing strip 17 are installed.

[0054] During the braking process: the piston 18 moves outward under the action of oil pressure, and the inner side of the rubber rectangular sealing strip 17 moves with the piston 18 under the action of interference assembly, while the outer side of the rectangular sealing strip 17 is limited by the sealing groove 16 , fixed at the installation position, so t...

Embodiment 3

[0058] The difference between this embodiment and Embodiment 1 is that: both the inner pliers body 2 and the outer pliers body 3 are provided with 4 sets of return components 4 for connecting the friction block 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com