Small-radius drilling equipment capable of accurately controlling drilling direction

A precise control and small-radius technology, which is applied in drilling equipment, directional drilling, drilling equipment and methods, etc., can solve the problems of poor precision control of turning holes, inability to realize small-radius turning, and inability to control accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

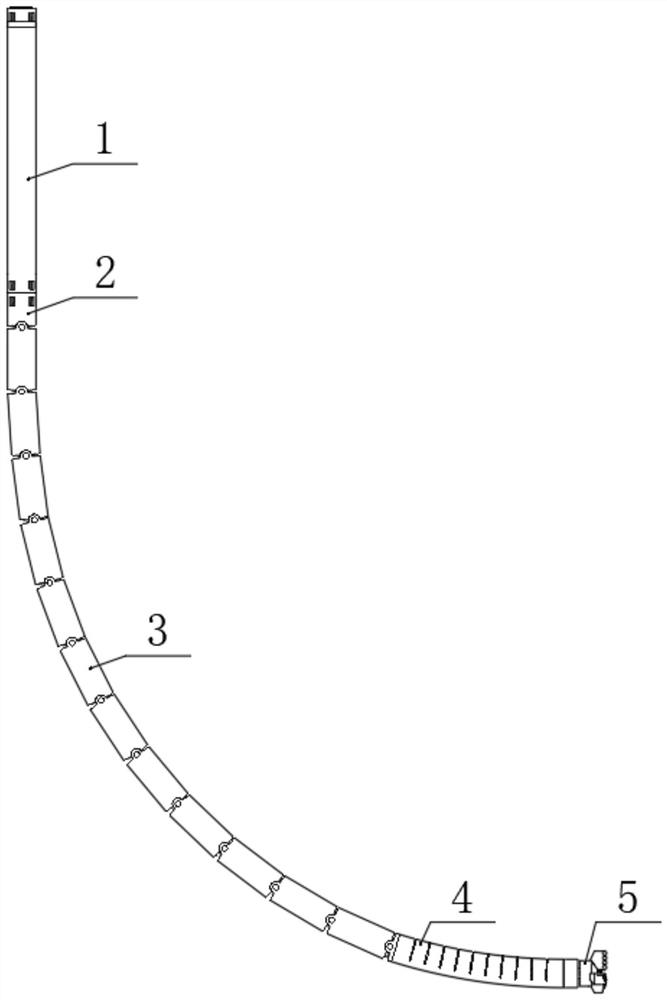

[0034] see figure 1 A small-radius drilling device capable of precisely controlling the drilling direction, comprising a connecting part 1, a passive turning part 3 and an active turning part, the second end of the connecting part 1 is fixedly connected to the first end of the passive turning part 3, The second end of the passive steering part 3 is hinged with the first end of the active steering part, and the second end of the active steering part is connected to the drill bit 5 in transmission; the active steering part drives the drill bit 5 to turn, so The drilling power is transmitted to the drilling part through the inside of the connecting part 1.

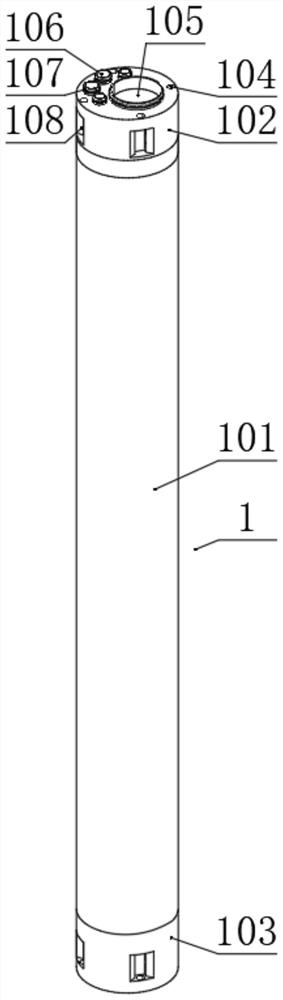

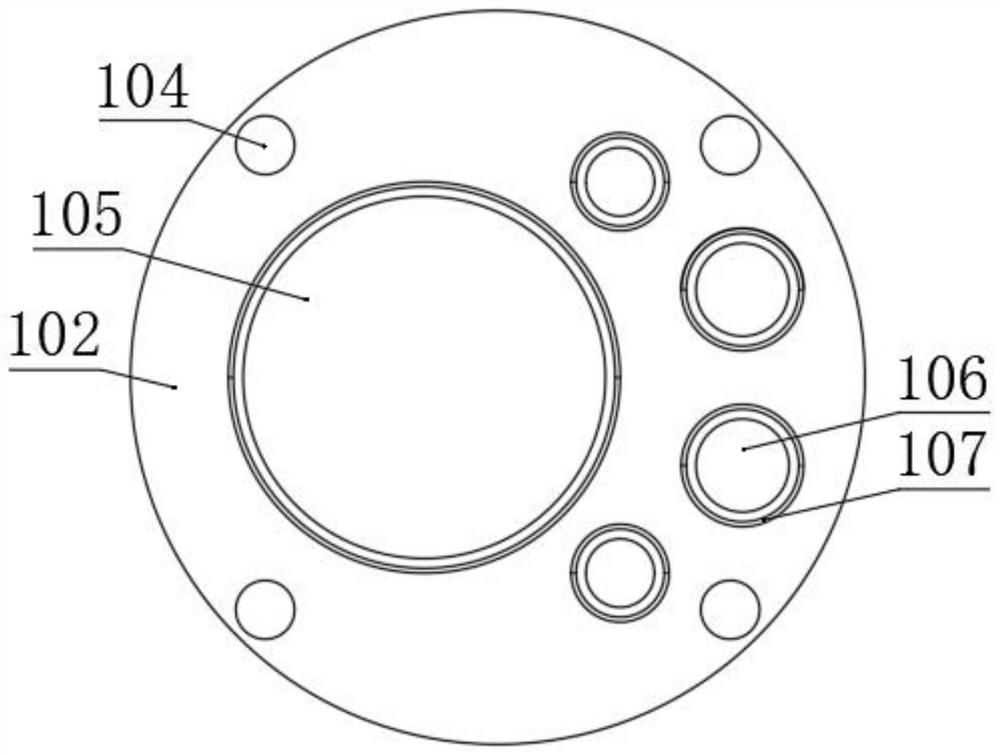

[0035] like Figure 2-3 As shown, the connecting part 1 includes a rod body 101, the first end of the rod body 101 is fixedly connected with a first end 102, the second end of the rod body 101 is fixedly connected with a second end 103, the first The structure of the end head 102 and the second end head 103 are the same, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com