Underground ditch cleaning method and equipment

A cleaning method and technology for underground ditch, applied in the field of machinery, can solve the problems of difficult to guarantee safety, time-consuming and labor-intensive efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

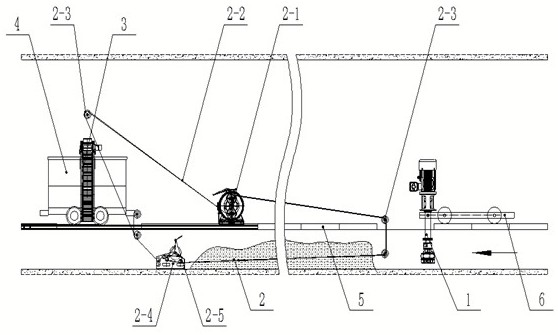

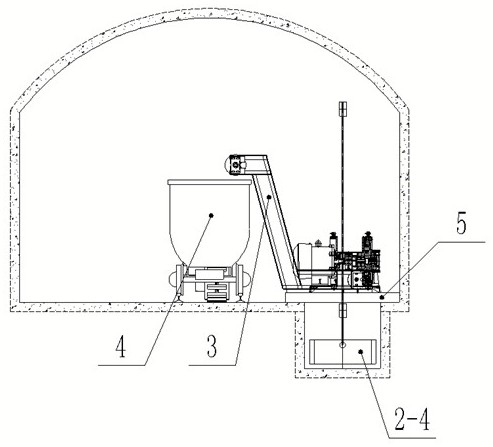

[0012] Underground ditch cleaning method of the present invention, at a specific location upstream of the gutter promoter upstream inflow liquid pump 1 pumping to a specific location downstream, cut off a section of dry slime region; then using harrow units 2 put into the slime rake the bucket, and then unloaded onto a scraper conveyor 3; slime scraper conveyor 3 to 4 transported into the tub, the tub 4 is directly carried away slime; ditch segment repeating the above cleaning method, until the water ditch clean-up is complete.

[0013] The method of cleaning drains downhole apparatus which comprises a pump 1, the liquid-harrow machine 2, the scraper conveyor 3 and the tub 4; 5 of the drain cover detachably disposed above the gutter, liquid pumps 1 drain cover 5 is placed on the platform by moving the carriage 6; the scraper conveyor 3 and the tub 4 is movably provided on the drain cover 5; said machine harrow 2 is provided to clean up dry Slurry the ditch region;

[0014] 2 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com