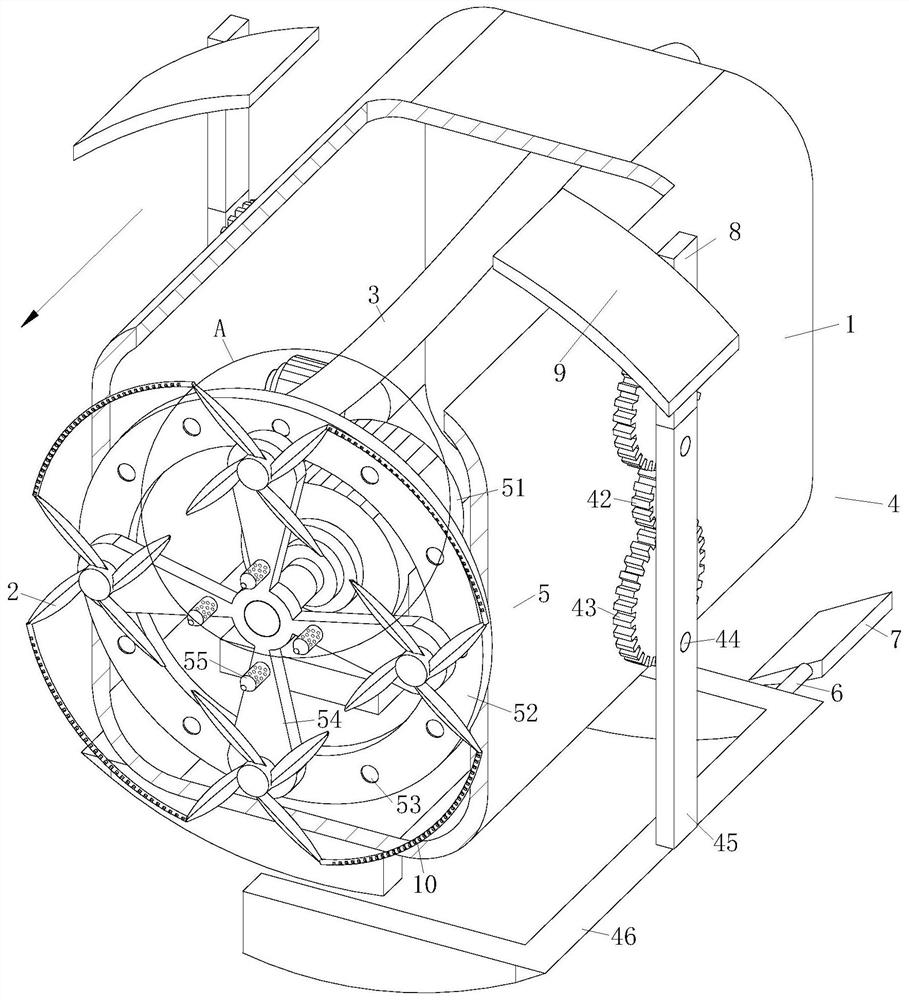

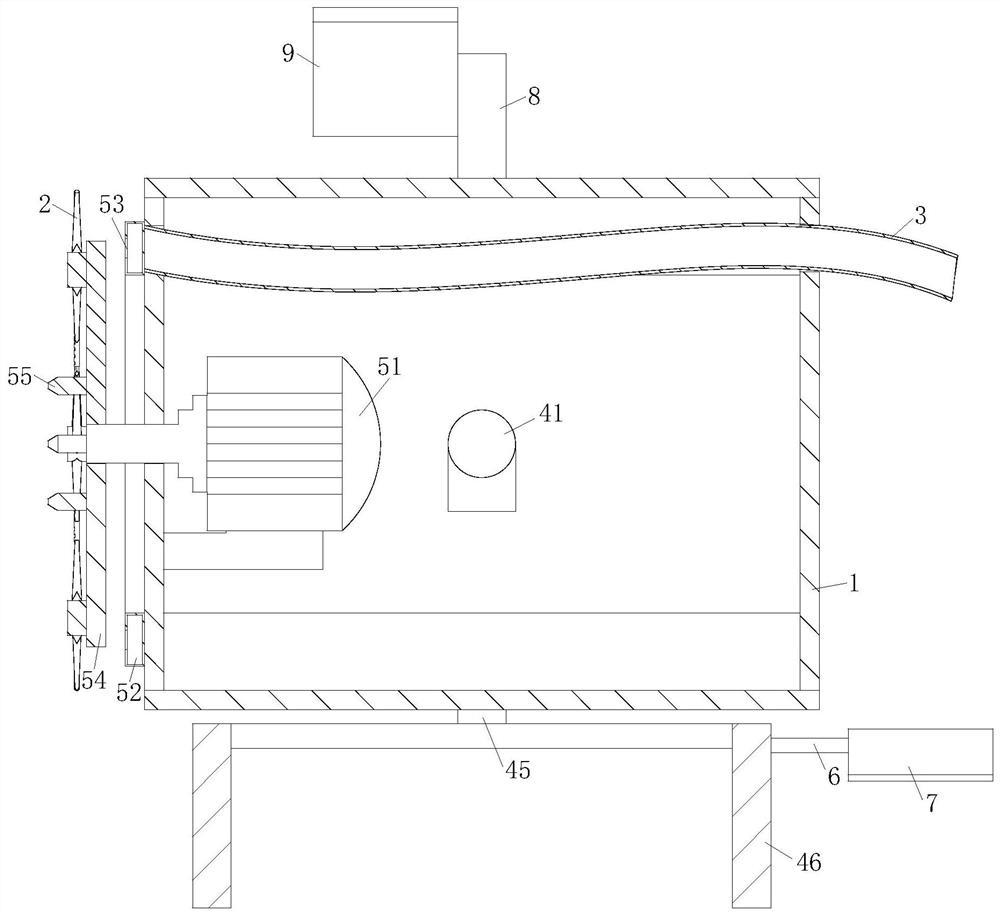

Sewage discharge pipeline silt remover

A technology for sewage pipes and dredgers, which is applied in the direction of cleaning sewer pipes, waterway systems, water supply devices, etc. It can solve the problems that the mud at the bottom is difficult to wash completely, the relative hardness of the mud becomes larger, and the progress of the dredger is hindered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

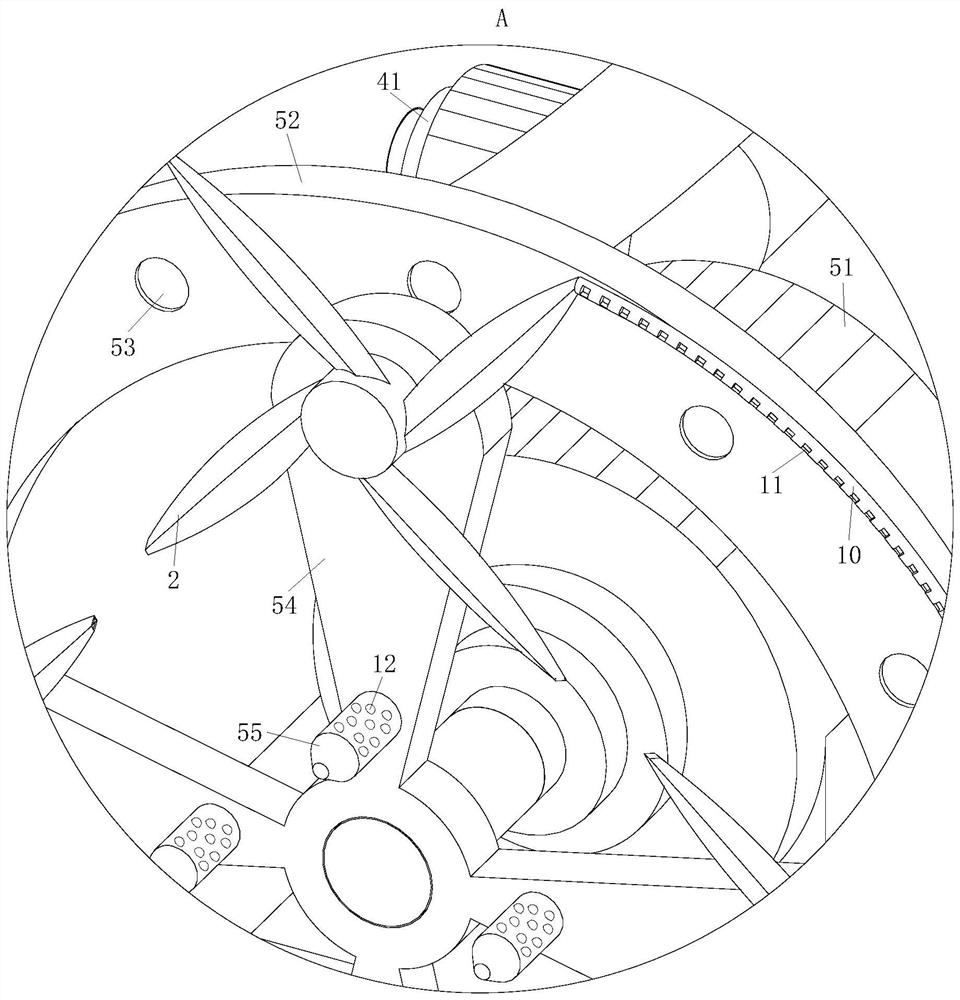

Examples

Embodiment approach

[0029] As an embodiment of the present invention, the rear end of the walking board 46 is fixedly connected with an elastic rod 6; One end is low; during work, the present invention is provided with elastic bar 6 and shovel plate 7 by the rear end of walking board 46, makes connecting rod 45 drive walking board 46 in the process of counterclockwise rotation, when connecting rod 45 is from the uppermost end In the process of forwarding to the lowermost end, the shovel plate 7 first contacts the pipeline, loosens the silt at the lower end of the pipeline, and then the elastic rod 6 and the walking plate 46 contact the pipeline; the present invention is provided with the elastic rod 6 and the shovel plate 7, so that When the desilting machine advances in the pipeline, it can also clean the silt at the bottom of the pipeline, which prevents the next blockage of the pipeline and improves the working effect of the desilting machine for the sewage pipeline.

[0030] As an embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com