Oxygen-hydrogen all-in-one machine

An all-in-one, oxygen-hydrogen technology, applied in the direction of oxygen preparation, respirator, electrolysis process, etc., can solve the problems of low safety, insufficient oxygen supply and insufficient pressure for users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

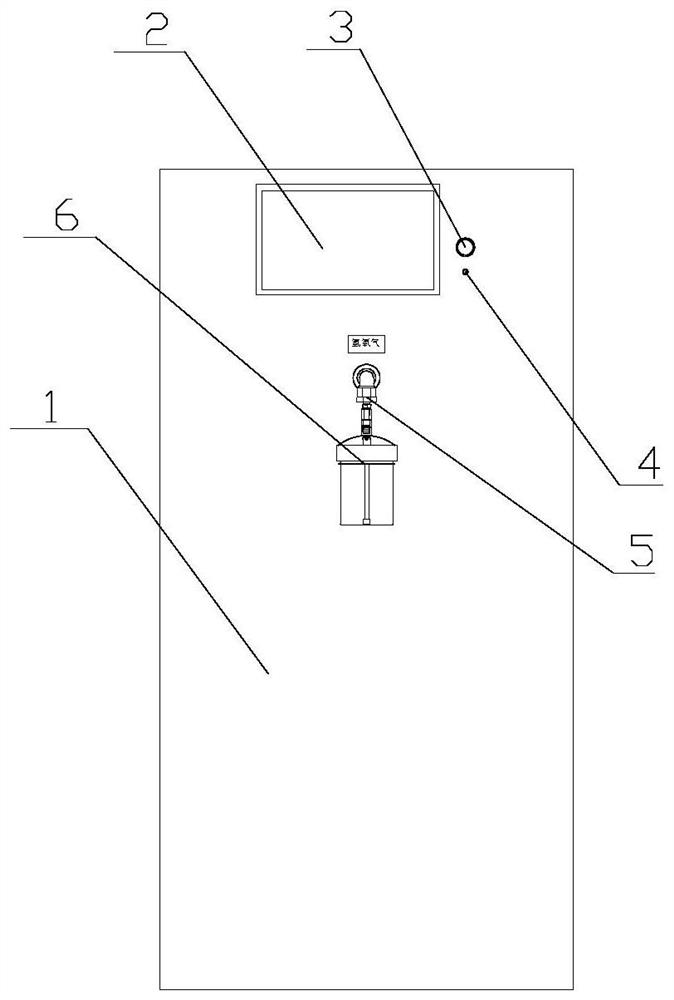

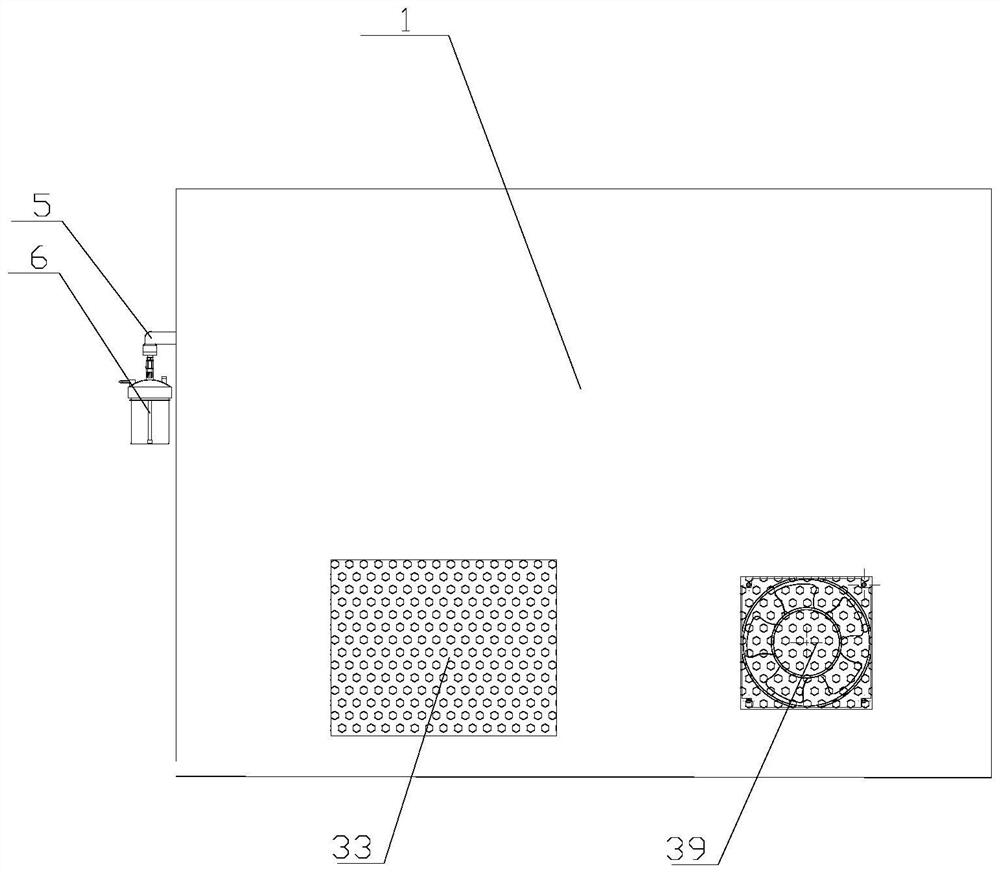

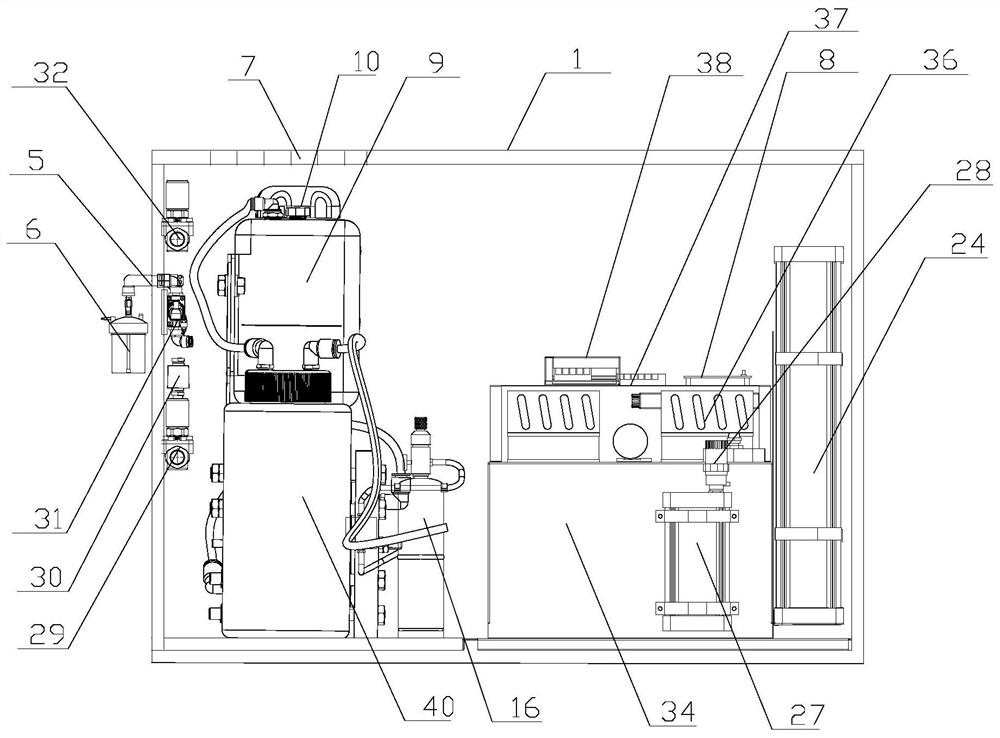

[0038] like Figure 1-4As shown in , 9, the embodiment of the present invention provides an oxygen-hydrogen integrated machine, which includes a machine casing 1, and a molecular sieve oxygen production module and an electrolytic hydrogen production module are arranged in the machine casing 1. One side of the housing 1 is provided with an oxygen-hydrogen interface 5, and the molecular sieve oxygen production module and the electrolytic hydrogen production module respectively pass an oxygen pressure regulating valve 28 and a hydrogen pressure regulating valve 17 so that the output of oxygen and hydrogen has the same The air pressure of the oxygen pressure regulating valve 28 and the output end of the hydrogen pressure regulating valve 17 are respectively provided with an oxygen restricting hole 30 and a hydrogen restricting hole 18, and oxygen and hydrogen pass through the oxygen restricting hole 30 and the hydrogen gas restricting hole 18. The hydrogen restricting hole 18 is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com