Anti-condensation automatic sanding device

A sand-spreading device and anti-condensation technology, which is used in drying gas layout, locomotives, dryers, etc., can solve the problems of easy agglomeration of sand, unsmooth sand-spreading operation, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

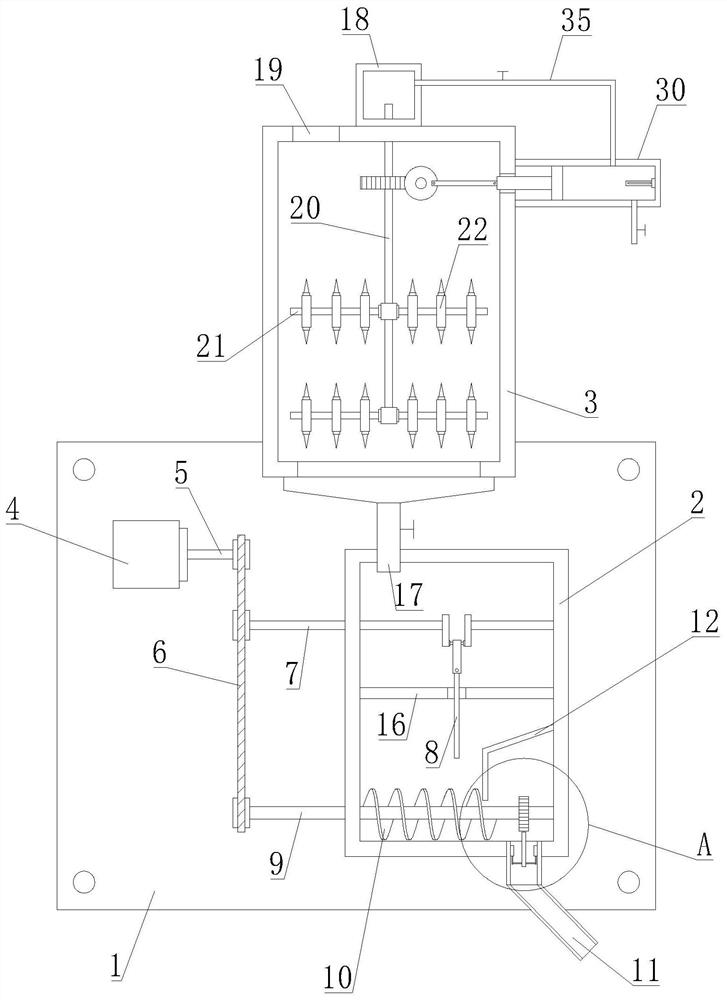

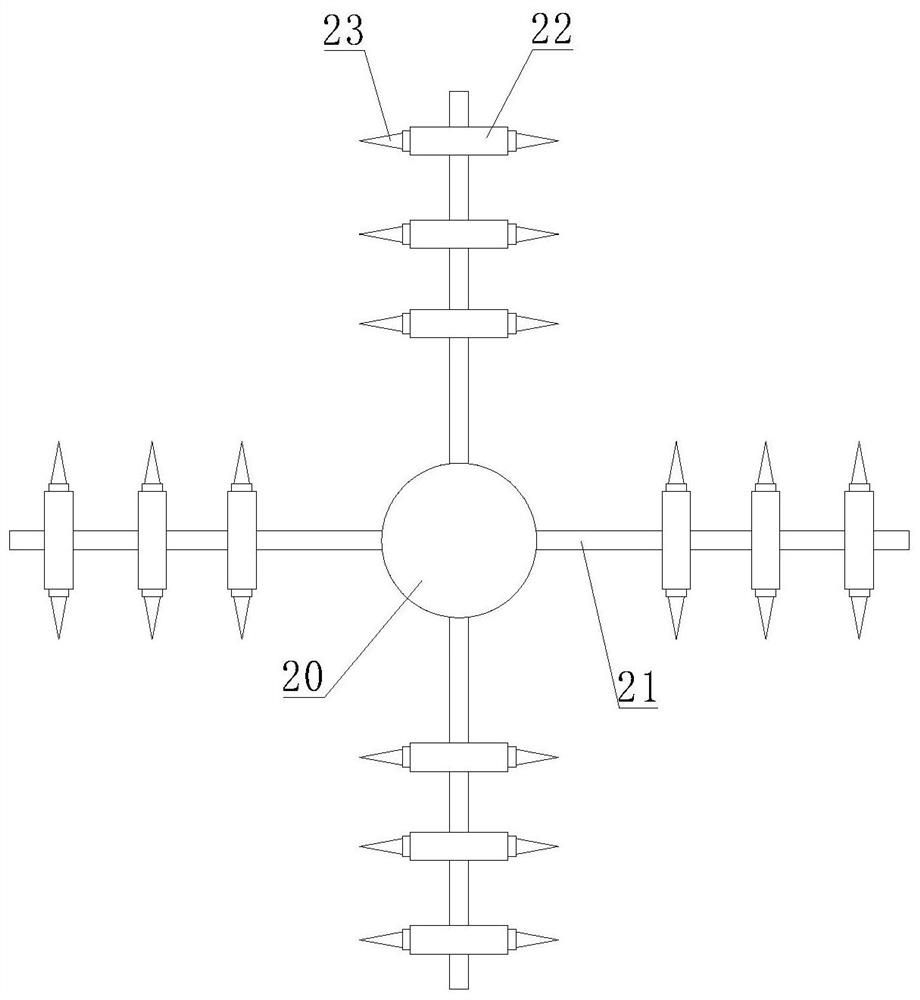

[0032] Such as Figure 1-4As shown, an anti-condensation automatic sand spreading device proposed by the present invention includes a mounting plate 1, a sand holding bucket 2, a sand storage box 3, a sand discharge pipe 11, a sand conveying pipe 17 and a sand filling port 19, and the mounting plate 1 It is fixedly installed on the mining electric locomotive by bolts, and the sand bucket 2 is fixedly installed on the installation plate 1 by bolts. The sand tube 11 spreads the sand in the sand bucket 2 to the upper surface of the rail. The sand can increase the friction between the motor wheel and the rail to ensure the normal start and operation of the electric locomotive. The sand storage box 3 is fixed by bolts Installed on the installation plate 1 and located above the sand bucket 2, sand is stored in the sand storage box 3, and the top of the sand storage box 3 is provided with a sand filling port 19, and sand is added to the sand storage box 3 through the sand filling por...

Embodiment 2

[0037] Such as Figure 5-6 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the outer wall of the sand storage box 3 is fixed with a heating cylinder 30 by bolts, and an electric heating tube 33 is fixedly installed on the side of the heating cylinder 30 away from the sand storage box 3 , the electric heating tube 33 converts electric energy into heat energy to heat the gas in the heating cylinder 30 to make it into hot gas; a piston 32 is slidably arranged in the heating cylinder 30, and the piston 32 slides in the heating cylinder 30, and the piston 32 faces away from the electric One side of the heating pipe 33 is provided with a movable rod 31, and the other end of the movable rod 31 extends into the sand storage box 3 and rotates to connect the pull rod 29. The pull rod 29 pulls or pushes the movable rod 31, and the movable rod 31 makes the piston 32 in the heating cylinder 30 Carry out reciprocating motion in the horizontal direction; the seco...

Embodiment 3

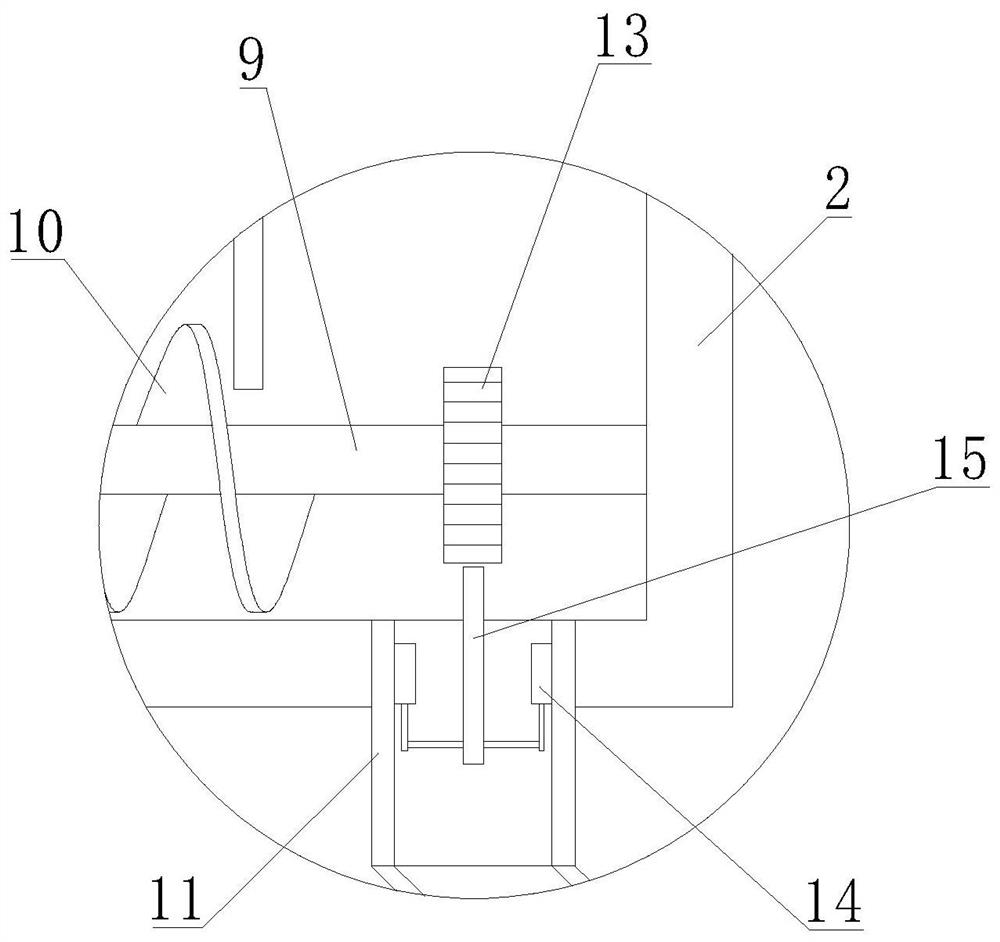

[0039] Such as Figure 7 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the elastic connection mechanism 14 includes a fixed column 1401, an insertion rod 1402, a spring 1403, a connecting rod 1404 and a slot 1405; the fixed column 1401 is vertically arranged on the sand discharge pipe 11, a slot 1405 is provided in the fixed column 1401; the insertion rod 1402 is vertically arranged and inserted into the slot 1405 upwards, the slot 1405 is provided with a guide groove, and the limit slider is located in the guide groove, and the limit slide The block slides up and down along the guide groove, and the inserting rod 1402 is slidably connected with the fixed column 1401 through the limit slider; the top of the slot 1405 is fixedly equipped with a spring 1403, and the bottom end of the spring 1403 is fixedly connected with the inserting rod 1402. Bar 1404 is horizontally arranged on the bottom end of inserting rod 1402 and is connected with loose san...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com