Automatic robot welding auxiliary tool

A technology of robot welding and auxiliary tooling, which is applied in the direction of welding/cutting auxiliary equipment, auxiliary devices, welding equipment, etc., and can solve the problems of increasing cost expenditure, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

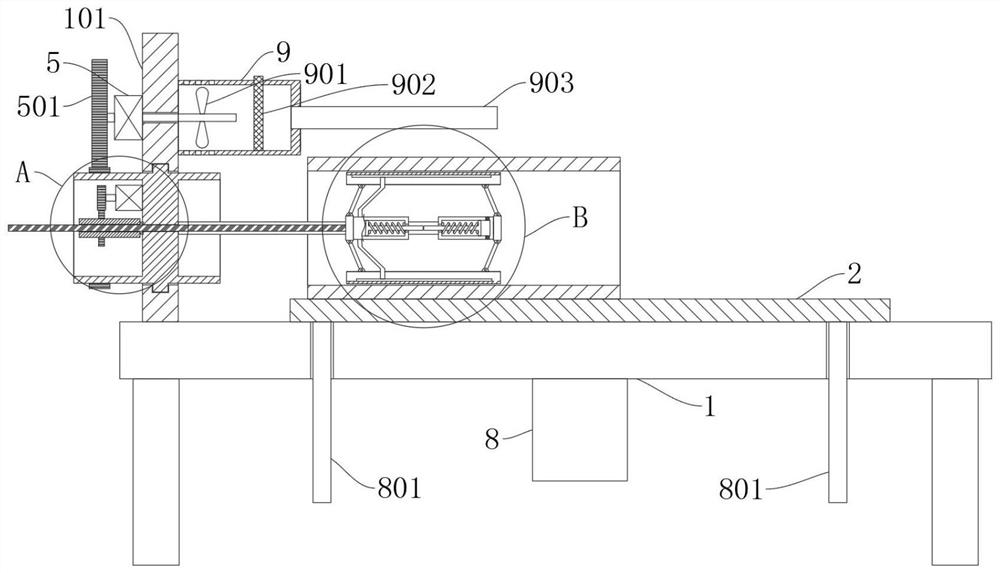

[0030] refer to Figure 1-6 , an automatic robot welding auxiliary tool, including a workbench 1, also includes: a mounting frame 101, fixedly connected to the workbench 1; a cylinder 4, connected to the mounting frame 101; a sliding rod 6, one end of which is fixedly connected to the cylinder 4 top; the first slider 601, sliding on the slider 6; the second slider 6011, fixedly connected to the end of the slider 6; the connecting rod 602, respectively rotatably connected to the two ends of the first slider 601 and the second slider 6011 Side; arc-shaped plate 603, rotatably connected to the end of connecting rod 602 away from first slider 601 and second slider 6011; driving mechanism, connected to cylinder 4 and first slider 601, for pushing the first slider The block 601 slides on the slide bar 6;

[0031] By placing the tubular part on the workbench 1, then pushing the tubular part towards the direction close to the slide bar 6, so that the slide bar 6 enters the inner circ...

Embodiment 2

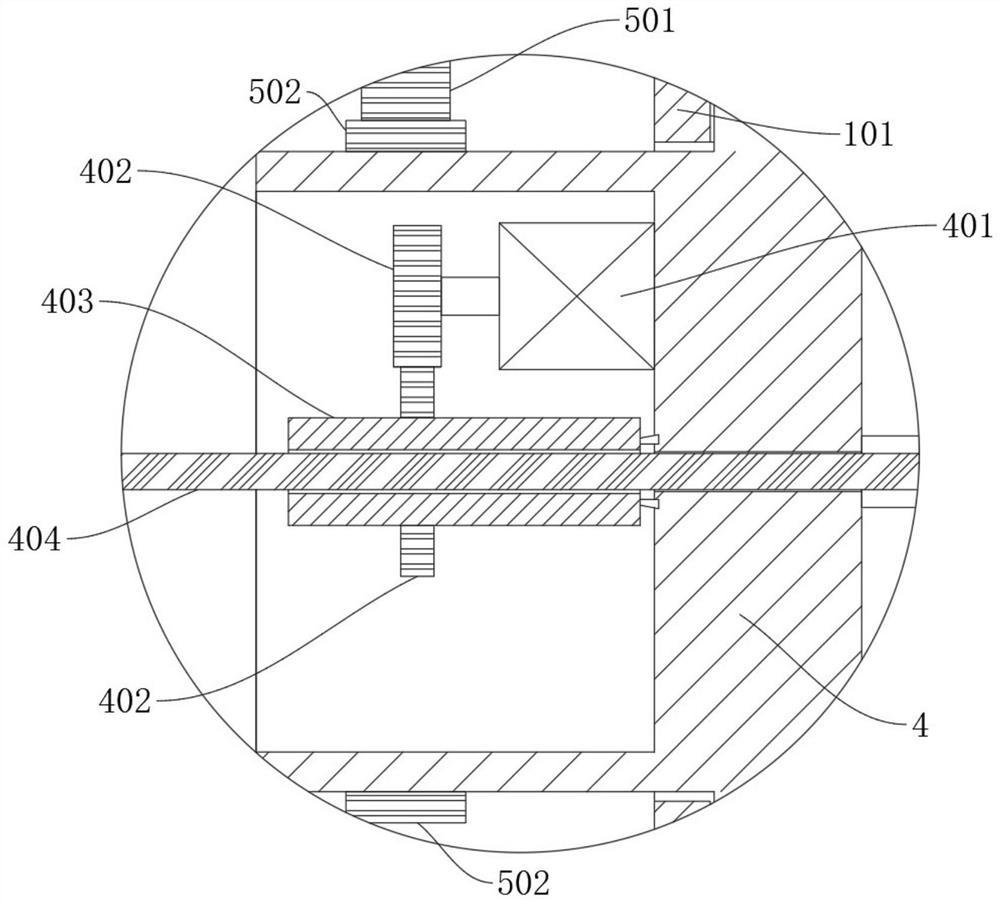

[0035] refer to image 3 , an automatic robot welding auxiliary tool, which is basically the same as that of Embodiment 1, furthermore: the driving mechanism includes a first motor 401, a sleeve 403, and a threaded rod 404, the first motor 401 is fixedly connected in the cylinder 4, and the sleeve One end of the cylinder 403 is rotatably connected to the cylinder 4, the sleeve 403 and the output end of the first motor 401 are fixedly connected with the first gear 402, the two sets of first gears 402 are meshed, and the threaded rod 404 is screwed into the sleeve 403 ;

[0036] The first motor 401 is electrically connected to an external control device;

[0037]By starting the first motor 401 and driving the first gear 402 to rotate, the sleeve 403 is rotated on the mounting bracket 101. The sleeve 403 is provided with threads corresponding to the threaded rod 404. When the sleeve 403 rotates, the threaded rod 404 will be in the The sleeve 403 moves inside, and the threaded r...

Embodiment 3

[0039] refer to figure 2 and 6 , an automatic robot welding auxiliary tooling, which is basically the same as that of Embodiment 1, furthermore: a support frame 2 is connected to the workbench 1, the support frame 2 is in a concave arc shape, and the surface of the support frame 2 is in a concave arc shape. There are balls 201, and the support frame 2 is located below the slide bar 6;

[0040] Place the tubular part on the support frame 2, then push the tubular part close to the slide bar 6, and through the friction between the tubular part and the ball 201, it is more labor-saving and easy to push the tubular part;

[0041] At the same time, the center line of the support frame 2 is coaxial with the slide bar 6 , so that the arc-shaped plate 603 can keep the tubular part coaxial with the slide bar 6 when fixing the tubular part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com