Fluid adsorption type laser cutting head

A laser cutting head and adsorption technology, which is applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of increased slag, incomplete removal, and slag drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

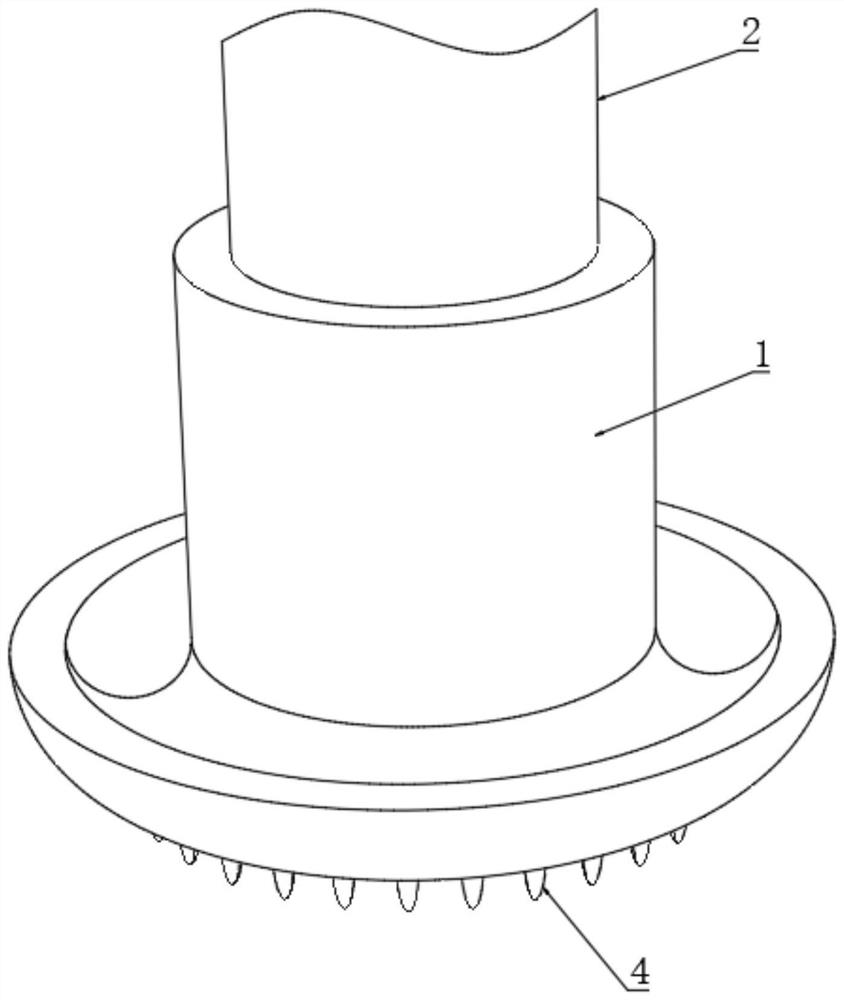

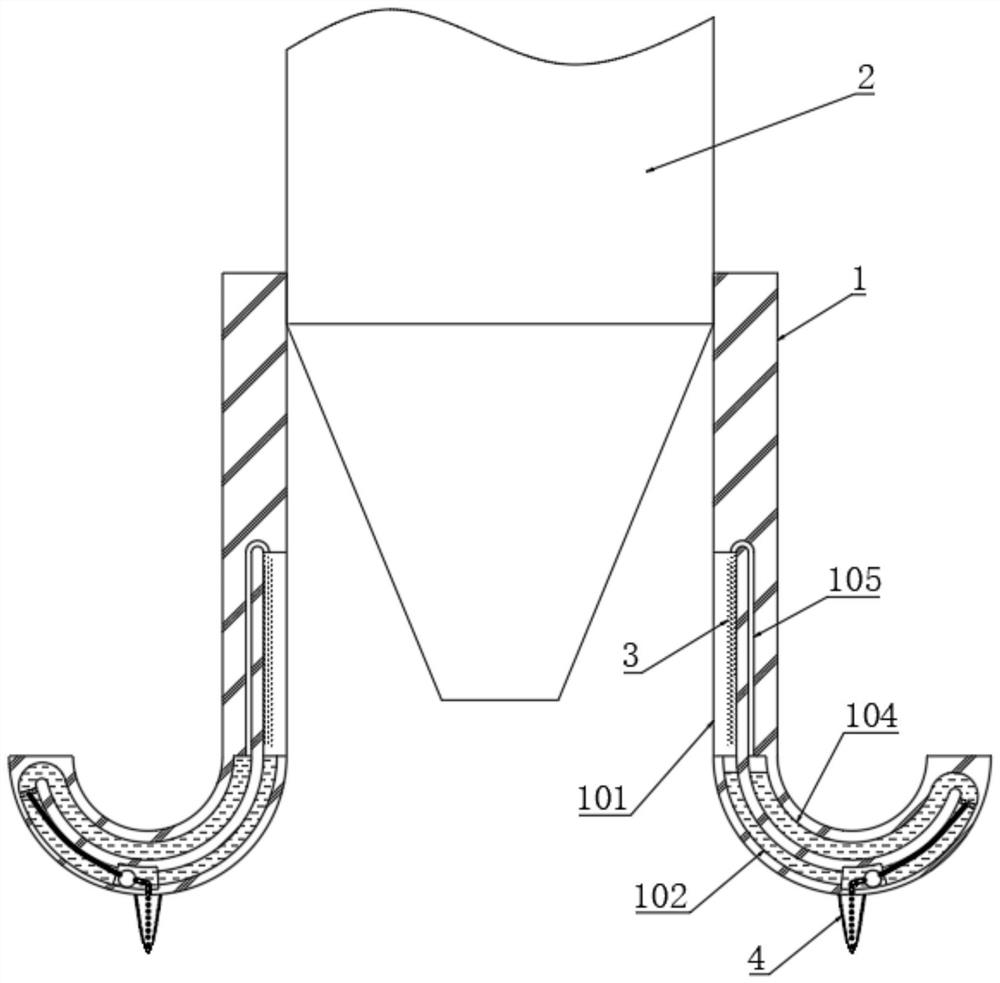

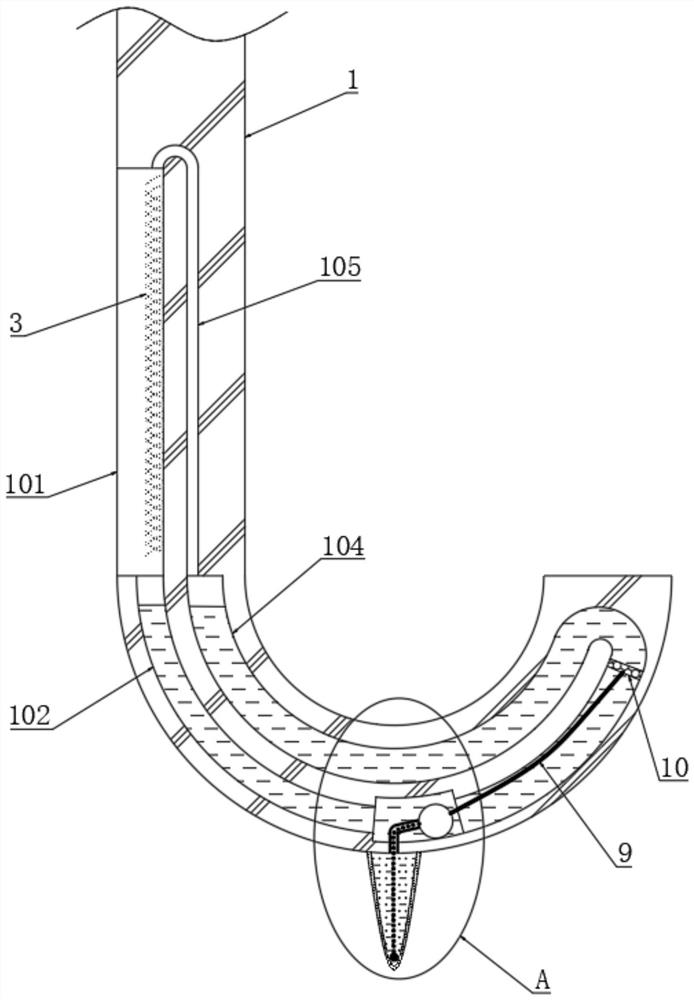

[0038] see figure 1 with figure 2 , a fluid adsorption laser cutting head, including a cutting head body 2, the outer end of the cutting head body 2 is fixedly connected with a coil tube 1, the inner surface of the coil tube 1 is provided with an annular groove 101, and the inner wall of the annular groove 101 is fixedly connected There is an adsorption wool layer 3, and the adsorption wool layer 3 is composed of a plurality of uniformly distributed rubber soft silks. The lower inner wall of the annular groove 101 is provided with a plurality of evenly distributed liquid inlet channels 102, and the liquid inlet channels 102 are far away from the edge of the annular groove 101. One end is provided with a converging channel 103, and the end of the converging channel 103 away from the liquid inlet channel 102 is provided with a liquid collecting channel 104, and the upper surface of the annular groove 101 is provided with a plurality of evenly distributed liquid outlet channels ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com