Vibrating screening machine for asphalt concrete

A technology of asphalt concrete and vibrating sieve, which is applied in the direction of separating solids from solids with airflow, sieving, solid separation, etc., which can solve the problems of concrete sieving omission, sieve hole clogging, and incomplete sieving, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

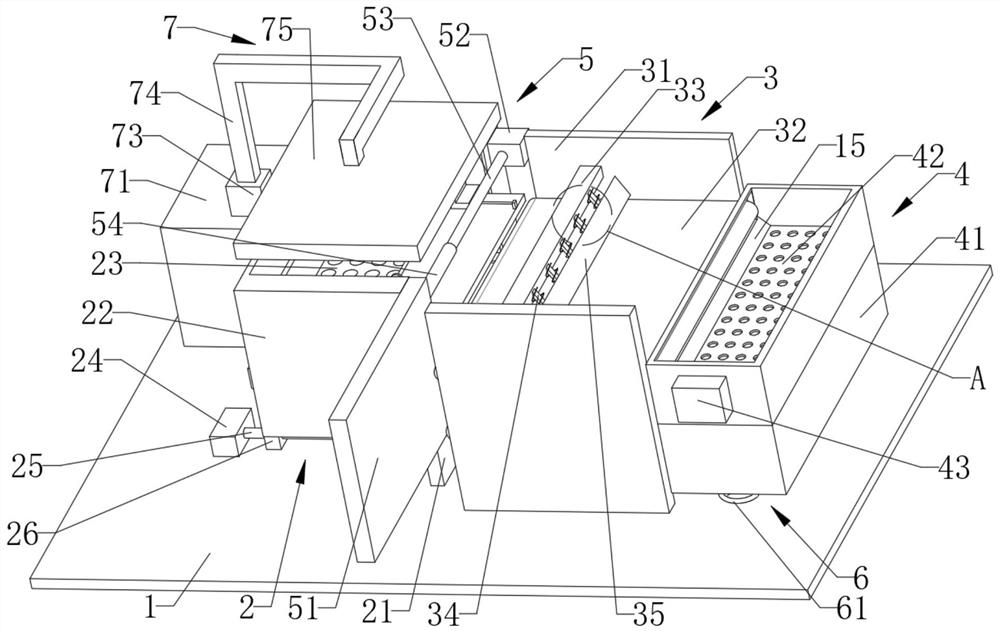

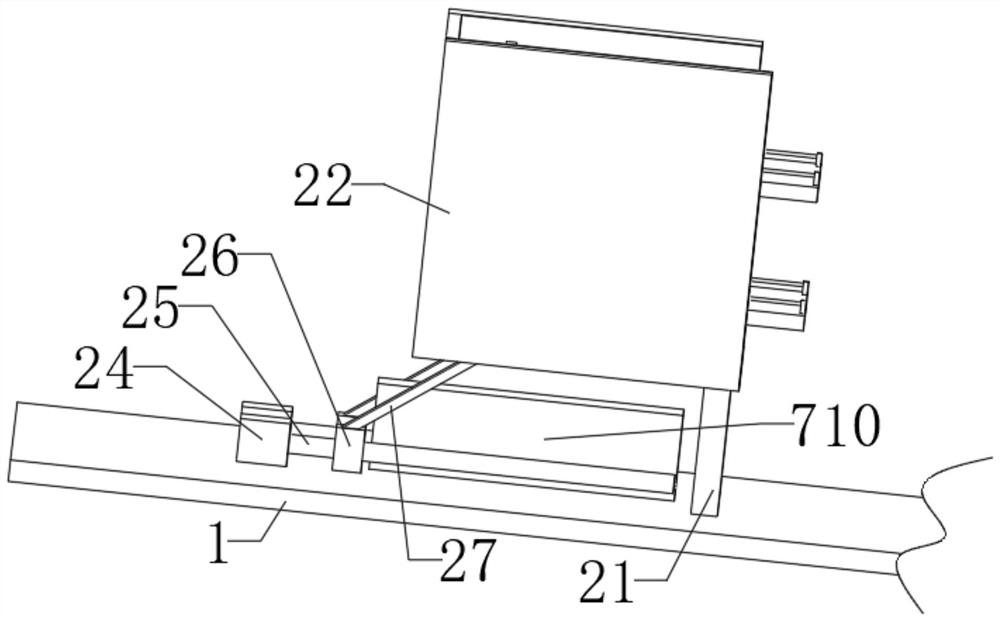

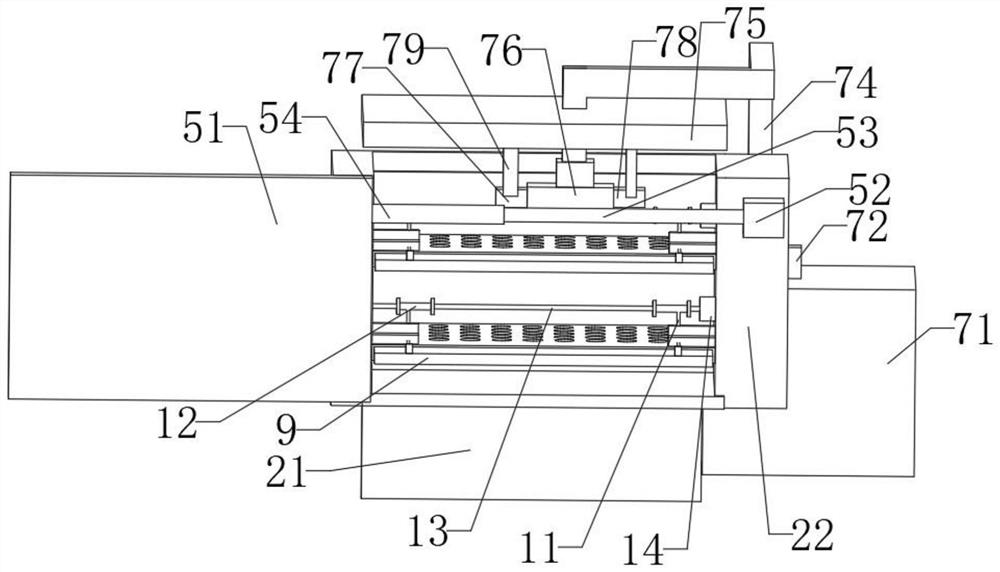

[0034] refer to figure 1 and figure 2 As shown, a vibratory screening machine for asphalt concrete provided by the present invention includes a base 1, the base 1 is set to provide support for the entire device, and one side of the base 1 is provided with a first screening assembly 2, a transmission assembly 3. The second screening assembly 4, the setting of the first screening assembly 2 is to screen the asphalt concrete, and the setting of the transmission assembly 3 is to send the screened asphalt concrete into the second screening assembly 4 , the second screening assembly 4 is in order to thoroughly screen the asphalt concrete and improve the effectiveness of the screening. The first screening assembly 2 includes a fixed platform 21, and the fixed platform 21 is set for the first screening box 22 for support, the fixed platform 21 is fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com