Full-automatic cloth-wrapping-free bean curd production system and hard bean curd processing technology

A production system, fully automatic technology, applied in the direction of food science, etc., can solve problems such as low production efficiency, aged tofu, shape deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

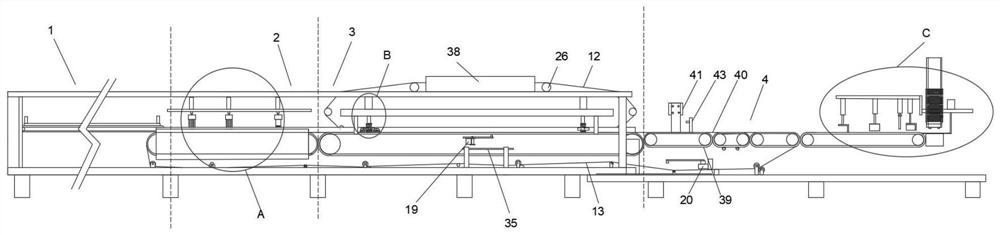

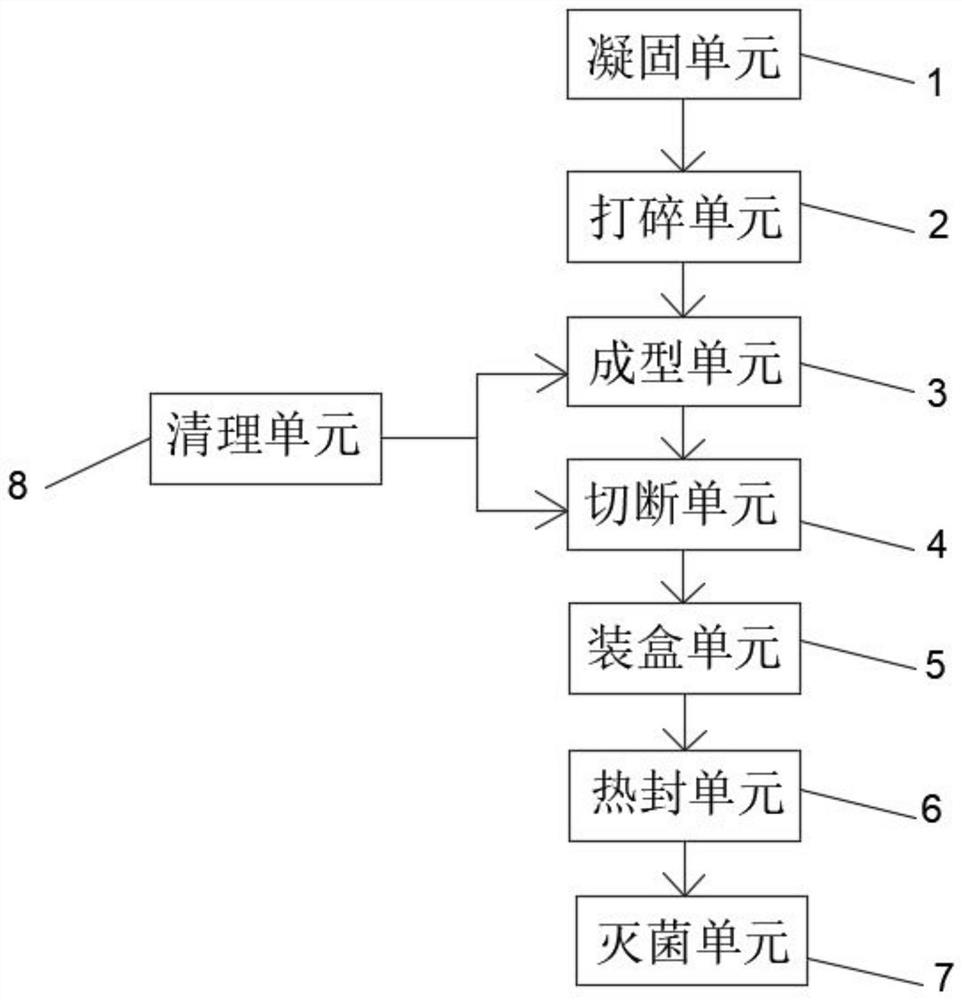

[0066] Such as figure 1 As shown, it is an embodiment of the present invention. For the traditional tofu production process, the basic process flow: cleaning-soaking-refining-filtering-boiling-solidification-forming-finished product, most of the existing mass-produced tofu is in the early stage Make it until it is solidified, and then complete the tofu molding and packaging through fully automated production. The technical solution of the present invention is: a fully automatic non-wrapped tofu production system, including a coagulation unit 1, which is suitable for marinating raw materials to form tofu flowers, and the coagulation unit 1 includes a coagulation belt part 9, and the tofu flowers are placed on the coagulation belt part 9 Upload and solidify;

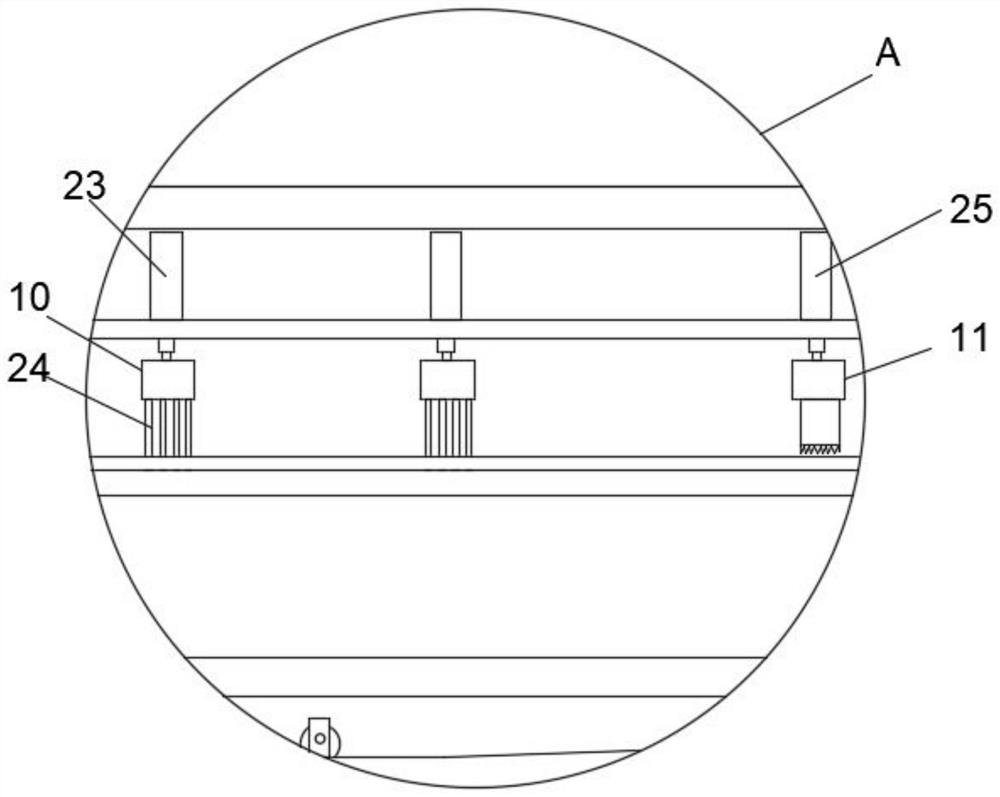

[0067] The crushing unit 2, the crushing unit 2 includes a crushing rod 10 and a fine-tuning rod 11, the crushing rod 10 is suitable for being inserted into the bottom of the tofu for crushing, and the fine-tuning rod 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com