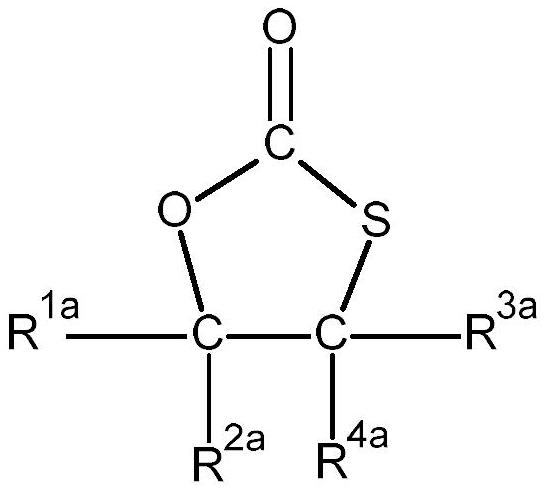

Method for preparation of thiocarbonates

A monothiocarbonate, carbocyclic technology, applied in organic chemistry and other directions, can solve problems such as performance problems, low availability of thiocarbonates, and low availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

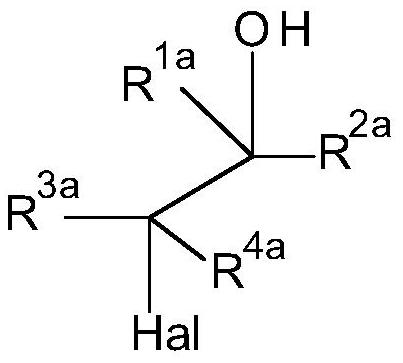

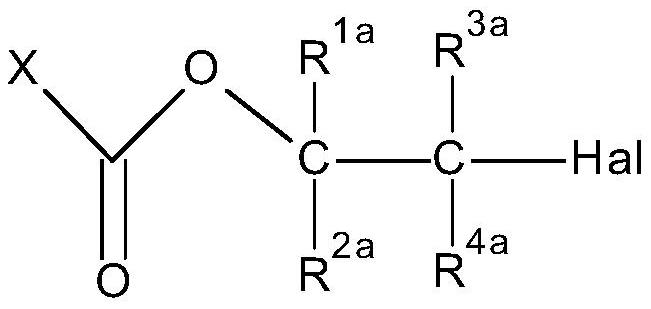

Method used

Image

Examples

Embodiment

[0179] GC analysis: Agilent Technologies 7890 A Network GC System

[0180] Column: DB1 (Agilent) 30m, Film thickness 1μm;

[0181] Carrier gas He; flow rate 1.0mL / min; split ratio: 50:1

[0182] T program: 50-300°C, heating rate 10°C / min; 30min isothermal

[0183] Temperature (injection system) 250°C

[0184] Preparation of 2-chloroethyl chloroformate, process step b)

[0185]

[0186] The synthesis was performed in a 1 L stirred tank reactor equipped with two condensers (-30°C and -78°C (dry ice)), phosgene dip tube, thermometer and dropping funnel. Phosgene (46.0 g, 0.5 mol) was introduced into the empty reactor at a temperature of 10°C until phosgene reflux was observed. Then 2-chloroethanol (161 g, 2.00 mol) was added via dropping funnel over 2 hours. The internal temperature recorded during this time can vary within 10-14 °C. Additional phosgene (404 g, 4.0 mol) was added simultaneously during the addition of 2-chloroethanol to ensure phosgene reflux throughout...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com