Device for automatically changing exhaust direction according to wind direction to avoid direct blowing for power distribution cabinet

A power distribution cabinet and wind direction technology, which is applied in substation/power distribution device housing, substation/switchgear cooling/ventilation, electrical components, etc., can solve the problem that the angle of cooling holes cannot be controlled, and the cooling holes of power distribution cabinets cannot be automatically controlled Open and close problems, to achieve the effect of changing the exhaust direction and enhancing the heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

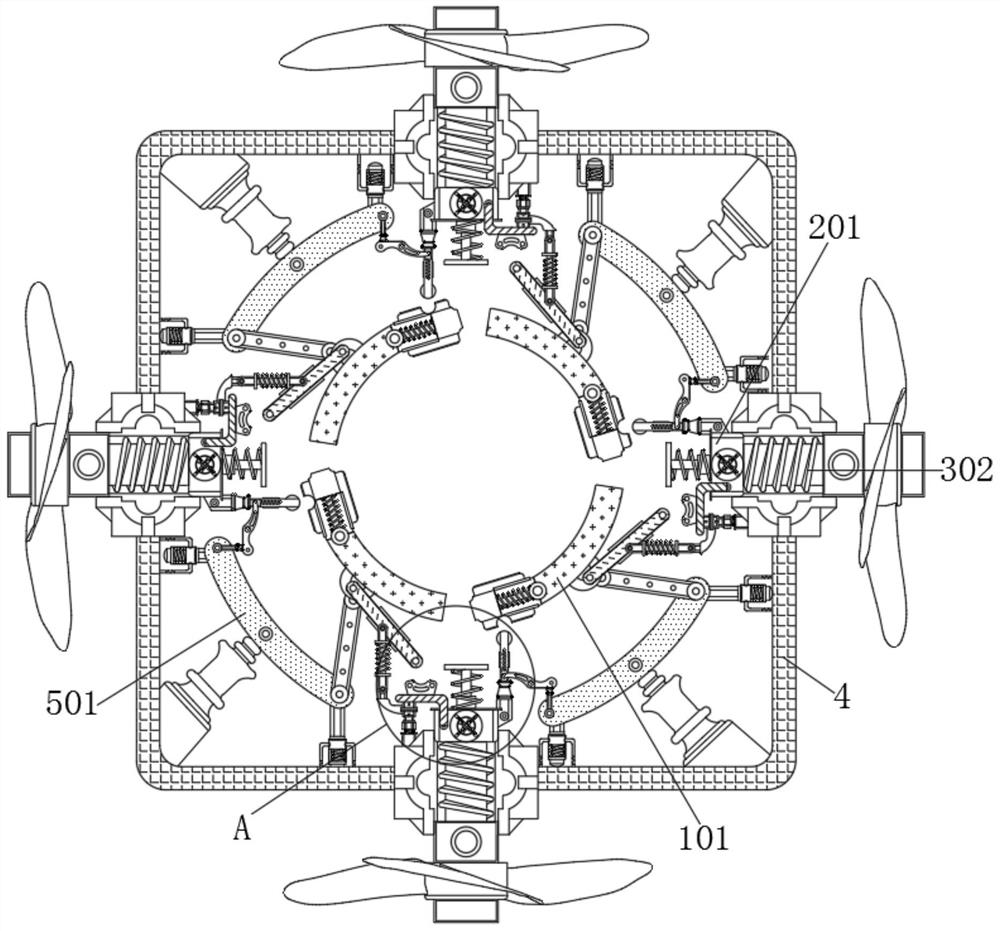

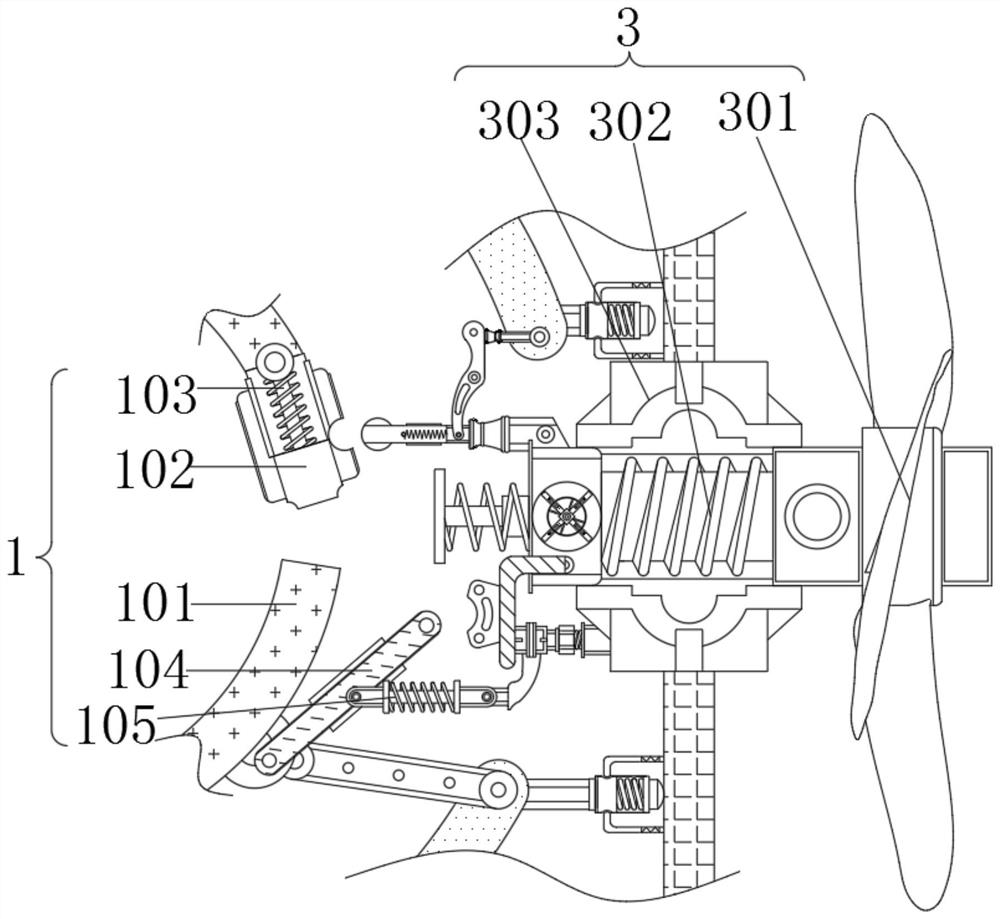

[0022] see Figure 1-3 , a device for a power distribution cabinet that automatically changes the exhaust direction according to the wind direction to avoid direct blowing, including a steering mechanism 1. A casing 4 is movably connected to the surface of the mechanism 3 , and a booster mechanism 5 is movably connected to the surface of the transmission mechanism 2 .

[0023] The inside of the steering mechanism 1 includes an installation barrel 101, a spacer 102, a spring 103, a push rod 104, and a tension spring 105. The surface of the installation barrel 101 is provided with a vent hole, and the spacer 102 is movably connected to the surface of the vent hole of the installation barrel 101. The two ends of spring 103 are respectively fixedly connected on the surface of installation bucket 101 and spacer 102, and one end of push rod 104 is movably connected on the surface of installation bucket 101, and one end of extension spring 105 is movably connected on the surface of p...

Embodiment 2

[0026] see Figure 4 , a device for a power distribution cabinet that automatically changes the exhaust direction according to the wind direction to avoid direct blowing. A casing 4 is movably connected to the surface of the mechanism 3 , and a booster mechanism 5 is movably connected to the surface of the transmission mechanism 2 .

[0027] The interior of the booster mechanism 5 includes a flexible plate 501, a pull rod 502, a telescopic rod 503, a support rod 504, and a rotating rod 505. One end of the pull rod 502 is movably connected to one end of the flexible plate 501, and one end of the rotating rod 505 is movably connected to the rotating rod. The other end of 505 , one end of support rod 504 is fixedly connected to the midpoint of flexible board 501 , and one end of telescopic rod 503 is fixedly connected to the end of flexible board 501 close to pull rod 502 .

[0028] One end of the flexible plate 501 close to the pull rod 502 moves inwardly, and the other end of ...

Embodiment 3

[0030] see Figure 1-5 , a device for a power distribution cabinet that automatically changes the exhaust direction according to the wind direction to avoid direct blowing, including a steering mechanism 1, and the inside of the steering mechanism 1 includes a mounting bucket 101, a spacer 102, a spring 103, a push rod 104, and a tension spring 105 , the surface of the installation bucket 101 is provided with a ventilation hole, the spacer 102 is movably connected to the surface of the ventilation hole of the installation bucket 101, the two ends of the spring 103 are respectively fixedly connected to the surface of the installation bucket 101 and the spacer 102, and one end of the push rod 104 is movable It is connected to the surface of the installation barrel 101 , and one end of the extension spring 105 is movably connected to the surface of the push rod 104 .

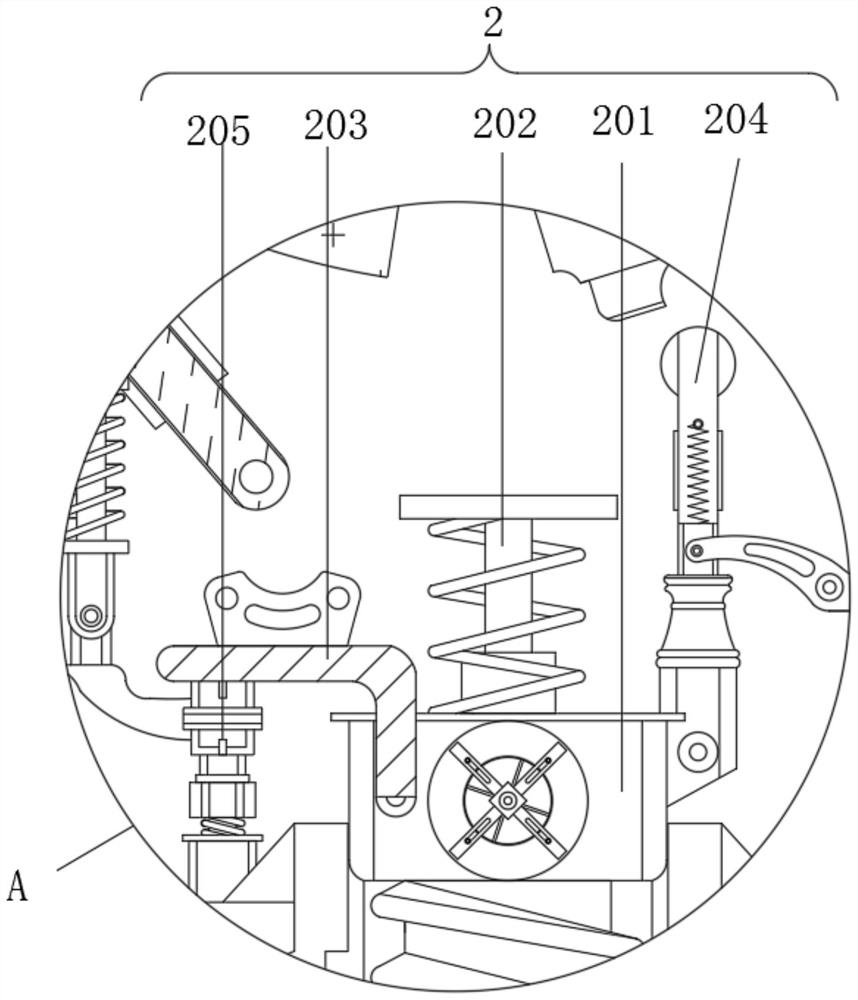

[0031] The surface of the steering mechanism 1 is movably connected with a transmission mechanism 2, and the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com