Preparation device, method and test method of sample for cable sheath shape measurement

A technology for preparing a device and a sheath, which is applied in the field of cable sheath structure and size testing, can solve problems such as sheath deformation, inability to accurately reflect the outer sheath size, etc., so as to avoid measurement errors, test results are true and reliable, and ensure measurement normalized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

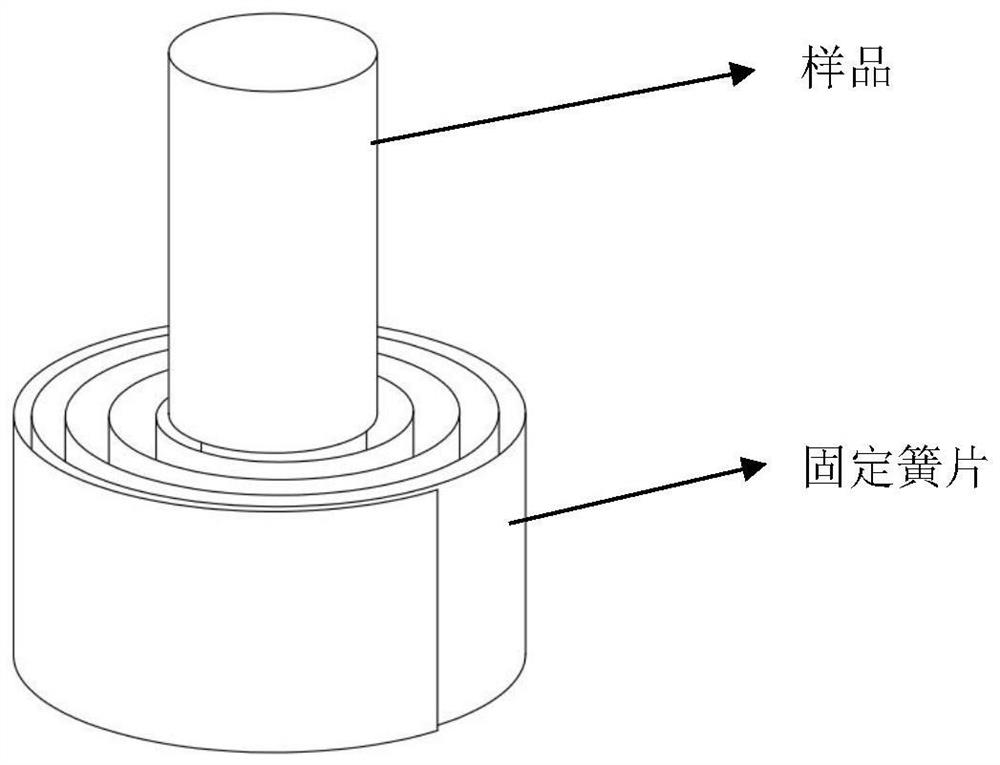

Image

Examples

preparation example Construction

[0029] The invention provides a method for preparing a sample for measuring the shape of a cable sheath, comprising the following steps:

[0030] (1) Embedding and fixing: the sheath sample with the cable core removed is vertically inserted into the epoxy resin, and the epoxy resin is completely cured to obtain the sheath sample embedded in the epoxy resin;

[0031] The epoxy resin, preferably bisphenol A type epoxy resin, is added with an accelerator so that its viscosity is preferably in the range of 200-1200mPa·s, the curing time at room temperature is between 0.5-4 hours, and the light can pass through after curing. The rate is greater than or equal to 50% and the Shore hardness is not less than 60HD. The accelerator is an organic solvent such as polybutadiene peroxide, which changes the viscosity and curing time of the resin;

[0032] In order to achieve batch measurement, the prepared sample for cable sheath shape measurement needs to have good imaging performance to re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com